Single point to double point and double point to single point information

Single point to double point information

This example shows how to convert single point information from Modbus RTU to double point information for IEC 60870-5-104.

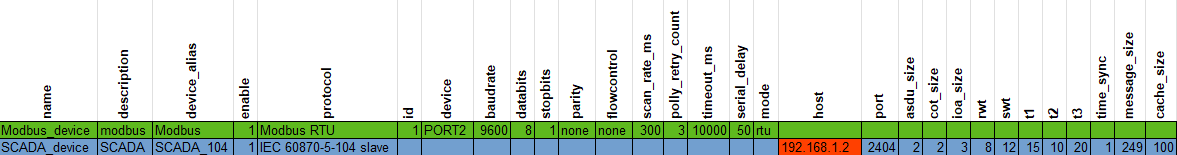

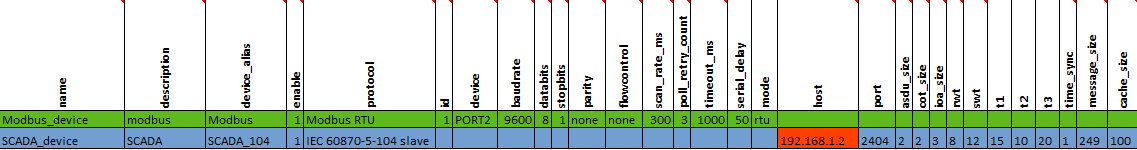

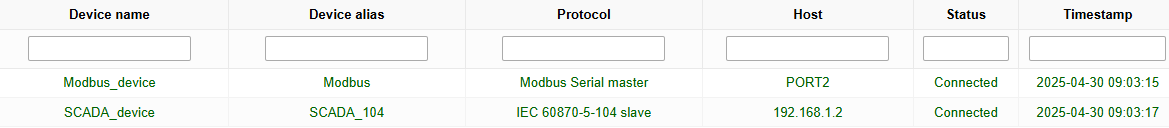

To begin, open the Devices sheet and define two protocols. One row should specify the Modbus RTU master configuration, including which physical port on WCC Lite will be used for communication. Another row should define the IEC104 slave protocol and its network parameters. Make sure all other fields follow the requirements of your setup.

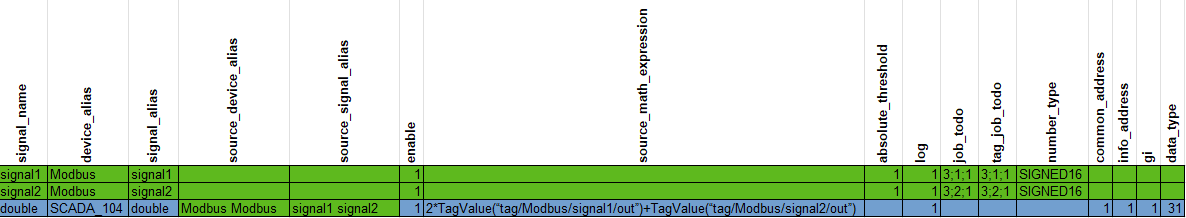

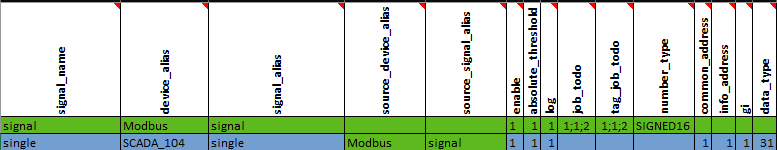

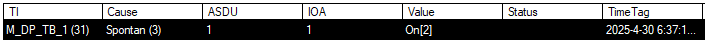

In the Signals sheet, define two separate Modbus input signals with distinct aliases. These signals will represent the two bits used to build the double point status. Then create a signal for the IEC104 slave with data type 31 ("M_DP_TB_1" Double-point information with time tag). In the source alias field, write both signal aliases separated by a space. This way, both Modbus signals will be used to generate a single double point value.

To determine the correct double point output, use a source math expression. The following logic is used:

If both signal1 and signal2 are 0, the double point result will be 0.

If both are 1, the result will be 3.

If signal1 is 1 and signal2 is 0, the result will be 2.

If signal1 is 0 and signal2 is 1, the result will be 1.

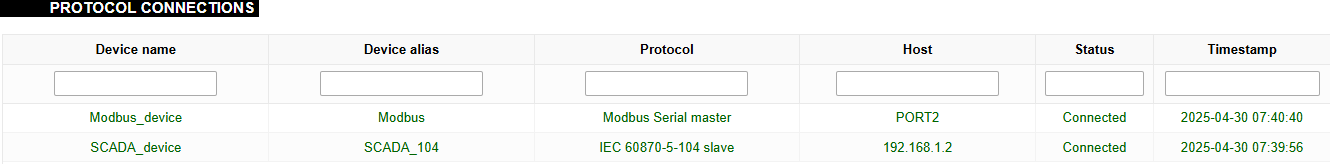

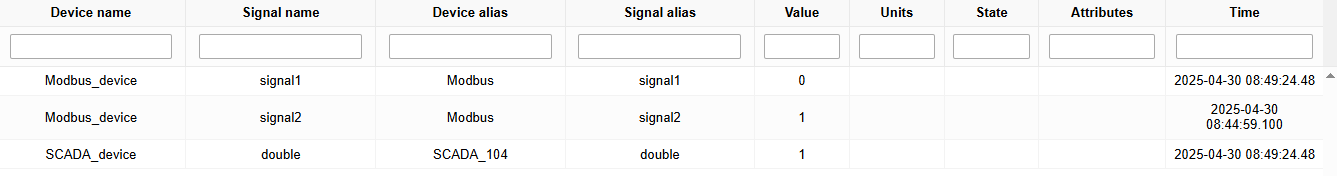

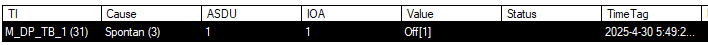

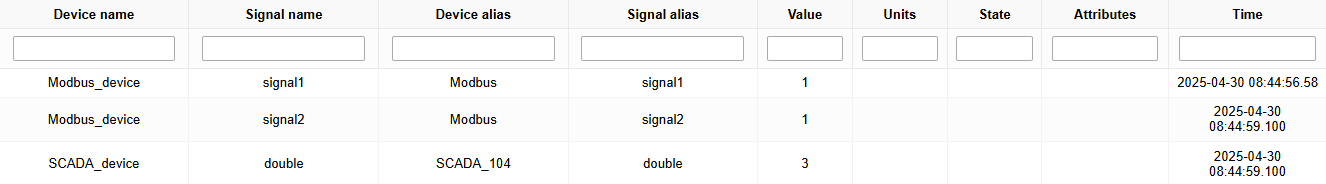

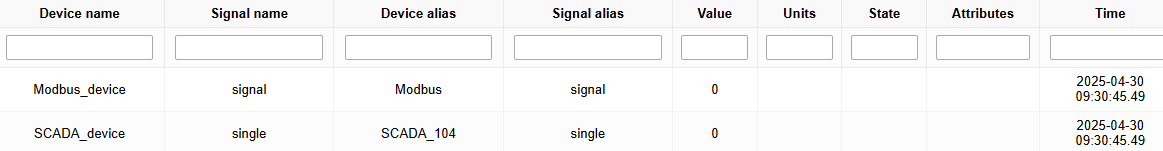

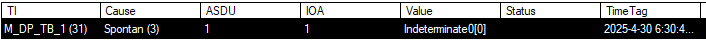

To test the setup, upload the Excel configuration to WCC Lite. Connect WCC Lite to your computer via Vinci expert (or other RS to USB converter) and run VINCI simulation program. Use one VINCI window configured as IEC104 master. Use a second VINCI window as a Modbus RTU slave. Ensure all settings (e.g. ports, baud rate) match your Excel configuration. Run both simulations and make sure both protocols are connected.

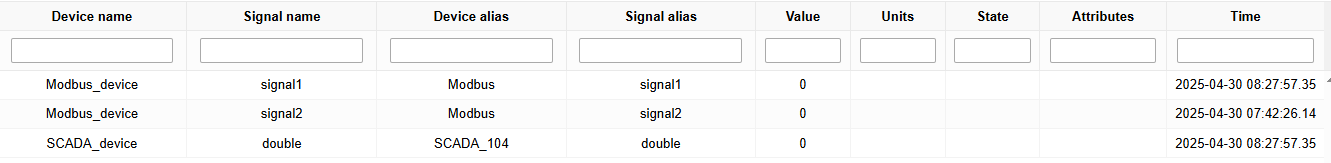

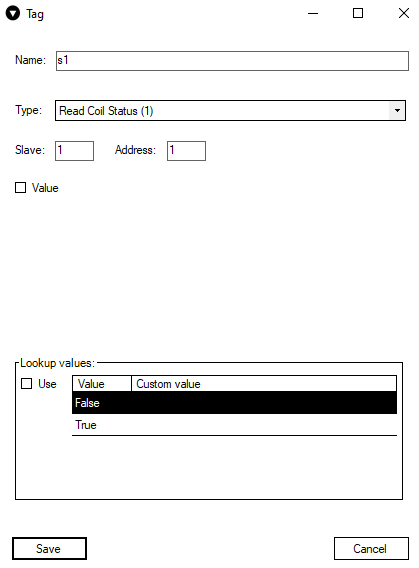

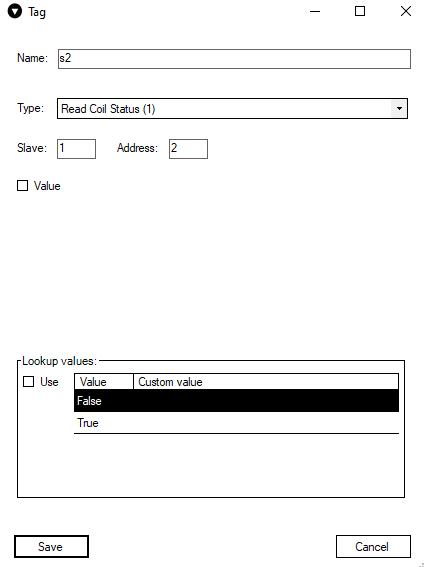

On the Modbus slave side, create a tag matching the address used in your configuration. Change the tag value to trigger a change in double point state, and observe the corresponding updates in the IEC104 master tab or web interface

Double point to single point information

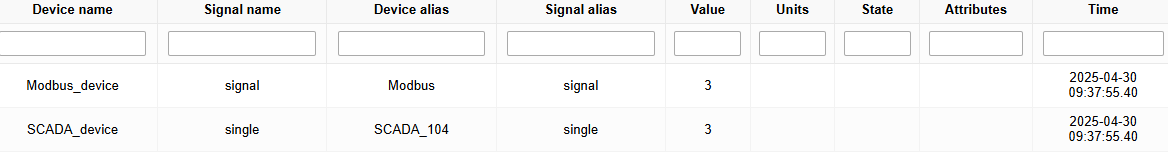

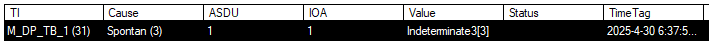

This example demonstrates how to convert double point information from IEC 60870-5-104 to single point data for Modbus RTU.

Begin with the Devices sheet. One row should define the IEC104 slave using the appropriate port and the IP address of the host computer. Another row should define the Modbus RTU master, specifying which physical port on WCC Lite will be used for communication. Make sure all protocol parameters are correctly set.

Open the Signals sheet. Define a Modbus signal using a function 1 (read discrete output coils). Then define a double point signal with data type 31 ("M_DP_TB_1" Double-point information with time tag) for the IEC104 protocol. Set the source alias to the Modbus signal you just created.

WCC Lite will interpret the double point values and convert them to single point logic.

| Value | State |

| 00 | indeterminate |

| 01 | off |

| 10 | on |

| 11 | indeterminate |

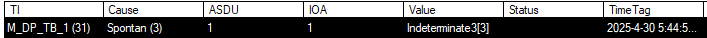

To simulate this setup, upload your configuration file to WCC Lite. Connect WCC Lite to your computer via Vinci expert (or any other RS to USB converter) and run VINCI simulation program. Start two simulations. One should act as the IEC104 master. The second should be a Modbus RTU slave, connected to the VINCI Expert port. Ensure all settings (e.g. ports, baud rate) match your Excel configuration. Run both simulations and make sure both protocols are connected.

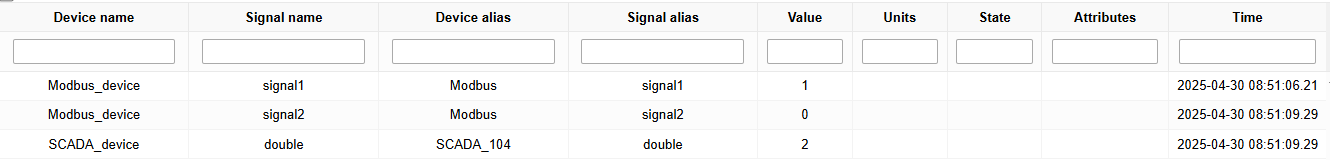

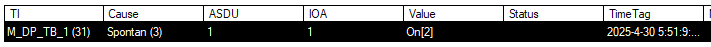

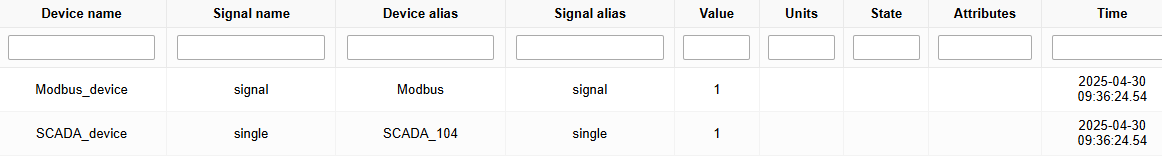

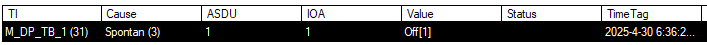

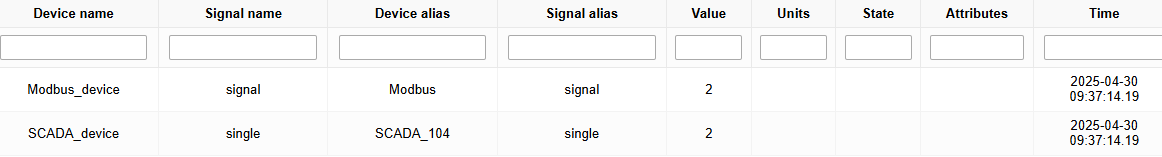

On the Modbus slave side, create a tag matching the address used in your configuration. Change the tag value to trigger a change in double point state, and observe the corresponding updates in the IEC104 master tab or web interface.

If Value box is checked, it means that this value is 1. Change tag values accordingly and observe the results on the web and IEC104 master tab:

Configurations:

Single point to double point --> Download

Double point to single point --> Download