IOMod Meter User Manual

1. Introduction

IOMod Meter is a compact-sized, stand-alone power meter for measuring analog AC input signals from low-power current and voltage sensors. It measures three phases of AC voltage and current amplitudes and phase shifts. Unlike IOMod 4Cs4Vs IOMod Meter only has three inputs for each phase current and voltage measurements. The measured and calculated values are transmitted to the host system via the communication protocol Modbus RTU, IEC 60870-5-101 or IEC 60870-5-103.

1.1 Features

- 3 AC current sensor inputs according to IEC 60044-8 (nominal value 225 mV);

- 3 AC voltage sensor inputs according to IEC 60044-7 (nominal value 3.25/√3 V);

- 32 samples per cycle;

- FFT-based calculation with harmonic information;

- Additional measurements of:

- Frequency (Nominal frequencies: 50 and 60 Hz; Frequency range: 45–65 Hz);

- Active, reactive, and apparent power;

- Neutral voltage, neutral current;

- Power factor;

- Phase angle;

- Firmware upgrade over USB, RS485;

- Configurable using the IOMOD Utility app for user-friendly setup;

- RS-485 interface with a switchable terminating resistor;

- Compact case with a removable transparent front panel;

- DIN rail mounting for seamless integration into industrial systems;

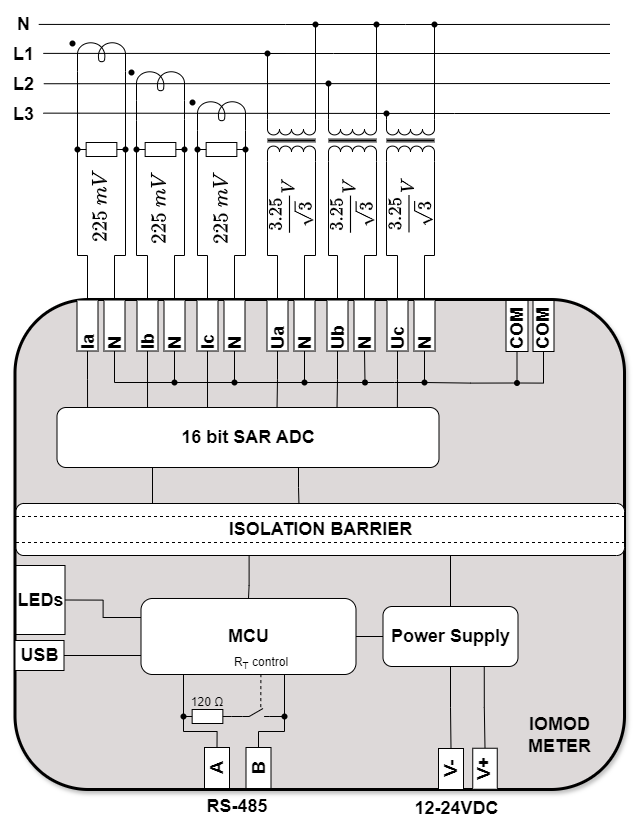

1.2 Block diagram

Fig. 1.2.1. IOMOD Meter internal structure and block diagram

2. Hardware data

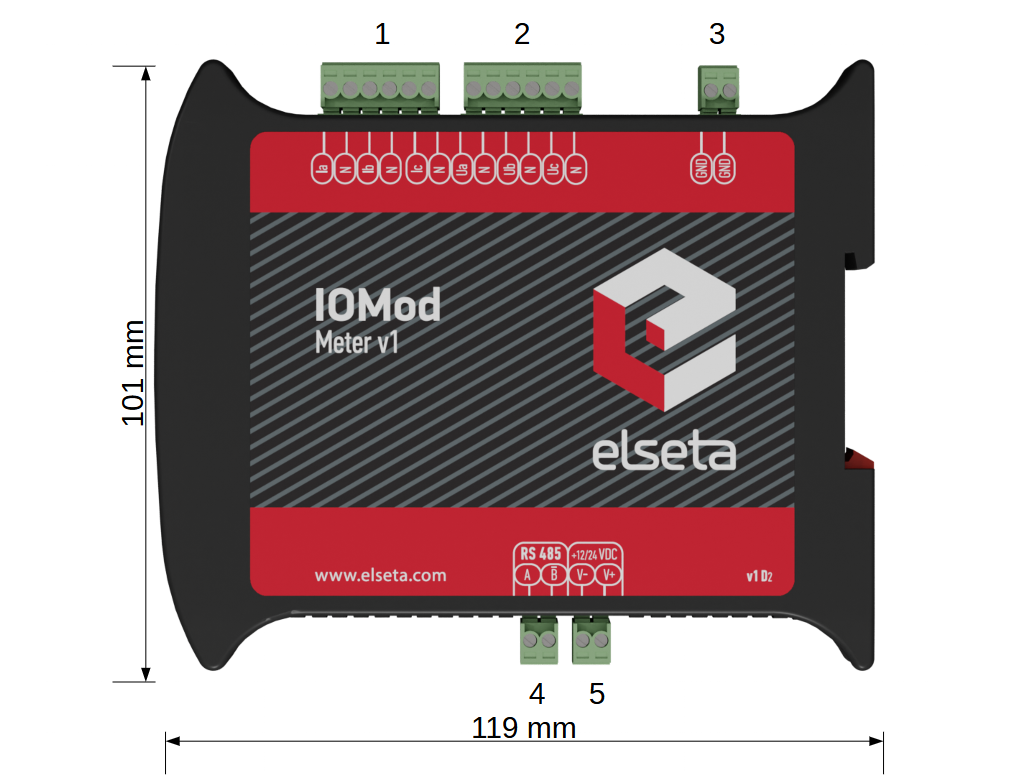

2.1 Mechanical drawings

Fig. 2.1.1. IOMod Meter side view with dimensions and terminal description. 1 – current measurement inputs; 2 – voltage measurement inputs; 3 – ground input for analogue measurements; 4 - RS485 interface; 5 - power supply input

Fig. 2.1.2 IOMOD Meter front view with measurements

2.2 Terminal Connections

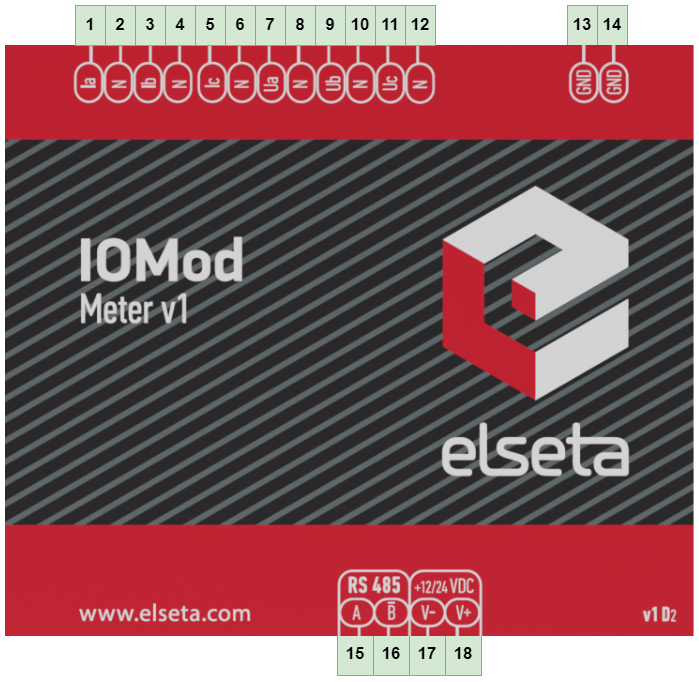

IOMod Meter has 18 terminals, which are depicted below:

Fig. 2.2.1 IOMod Meter terminal diagram

The description of each terminal can be found in the table below:

Table 2.2.1 Terminal Specifications

|

Terminal number |

Terminal name |

Description |

|

1 |

Ia |

Phase current 1 |

|

2 |

N |

|

|

3 |

Ib |

Phase current 2 or neutral current in case of I0 metered mode |

|

4 |

N |

|

|

5 |

Ic |

Phase current 3 |

|

6 |

N |

|

|

7 |

Ua |

Phase voltage 1 or phase current 1 in case of 3I3I connection mode |

|

8 |

N |

|

|

9 |

Ub |

Phase voltage 2 or phase current 2 in case of 3I3I connection mode, or neutral current in case of 3I3I connection mode, along with I0 metered mode |

|

10 |

N |

|

|

11 |

Uc |

Phase voltage 3 or phase current 3 in case of 3I3I connection mode |

|

12 |

N |

|

|

13 |

COM |

Analogue measurements common neutral terminals |

|

14 |

COM |

|

|

15 |

A |

RS-485 interface port |

|

16 |

B̄ |

|

|

17 |

V- |

Power source inputs |

|

18 |

V+ |

2.3 Status indication

IOMod Meter have 2 LEDs (Fig. 2.3.1), which indicate communication and power statuses.

Fig. 2.3.1. IOMod Meter LEDs physical location

The description of each IOMod Meter LED can be found in the table below:

Table 2.3.1. Description of LEDs.

|

Name |

LED color |

Description |

|

RX/TX |

🟢 (green) |

A blinking green light indicates active communication via the RS-485 interface. |

|

STAT |

🟢 (green) |

The power source is connected to the power supply input. |

|

🔵 (blue) |

IOMod Meter is connected to an external device via a USB mini cable. |

3. Technical information

Table 3.1. Technical specifications.

| System | ||

| Dimension | 101 x 119 x 17.5 mm |

|

| Case | ABS, black |

|

| Working environment | Indoor |

|

| Operating temperature | -40°C ... +85°C | |

| Recommended operating conditions | 5–60°C and 20–80%RH; |

|

| Configuration |

USB, RS485 |

|

| Firmware upgrade | USB, RS485 |

|

| Electrical specifications |

||

|

Inputs |

Resolution |

16 bits |

|

Input resistance |

~1 MΩ |

|

|

Input capacitance |

< 170 pF |

|

|

Input ranges |

±10 V (amplitude) |

|

|

Nominal values |

Current input: 225 mV (rms) Voltage input: 1.876 V (rms) |

|

|

Overvoltage protection for all inputs |

up to ±20 V (amplitude) |

|

| Power |

||

| Power Supply | 9–33 VDC (full range) |

|

| Current consumption | 40 mA @ 12 VDC, 20 mA @ 24 VDC |

|

4. Mounting and Installation

4.1 Connection Diagrams

In this chapter the various options of connecting the device to medium-voltage systems are discussed.

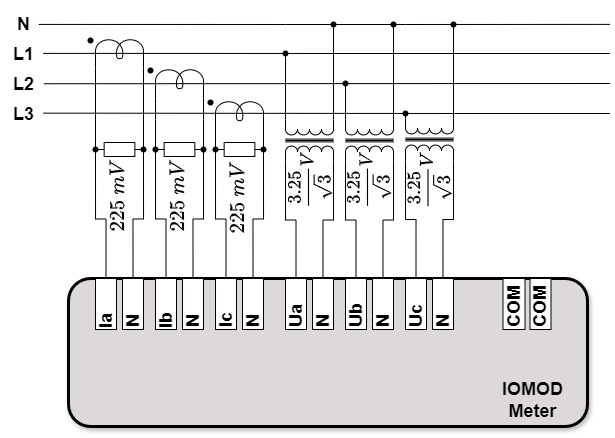

4.1.1 3 Low-Power Current Sensor, 3 Low-Power Voltage Sensors

In the case of 3I3U connection mode, IOMod Meter can be connected to a medium-voltage system by using low-power current and low-power voltage sensors (Fig. 4.1.1.1). In this scenario, the neutral current I0 and the neutral voltage U0 are calculated by taking a vector sum of appropriate measurements. IOMod Meter GND inputs are not required to be connected to the neutral line because they are interconnected with signal neutral inputs (Fig. 1.2.1).

Fig. 4.1.1.1. Connection diagram with 3 low-power current and 3 low-power voltage sensors

4.1.2 Fault Passage Indicator for two feeders

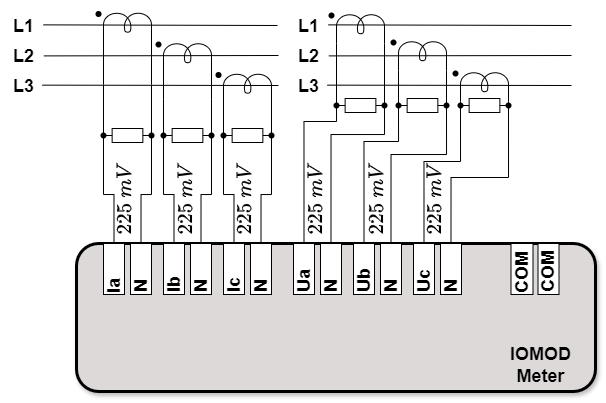

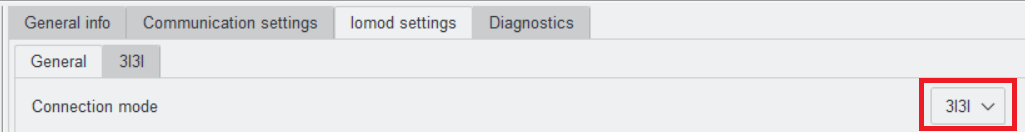

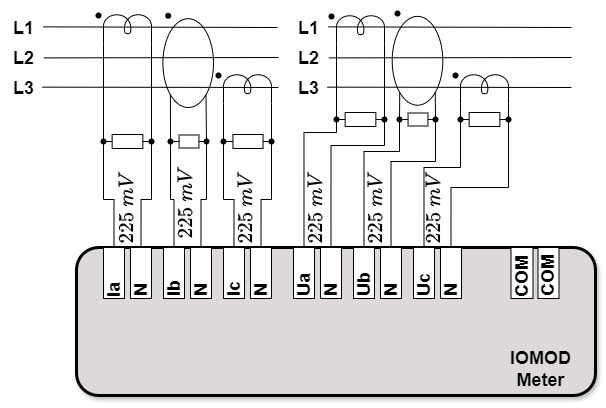

The special feature of IOMod Meter is the ability to perform the metering of two feeders (Fig. 4.1.2.1). In this case, 3I3I connection mode needs to be enabled in the IOMod Utility (Fig. 4.1.2.2).

Fig. 4.1.2.1. IOMod Meter connection diagram for two feeders

Fig. 4.1.2.2. IOMod Utility General settings tab with Connection mode set to 3I3I

This mode allows us to use IOMod Meter voltage inputs for current measurements, so that the currents of both feeders are measured simultaneously. In the connection scheme above (Fig. 4.1.2.1), IOMod Meter, each input is connected to the pair of feeders via low-power current sensors.

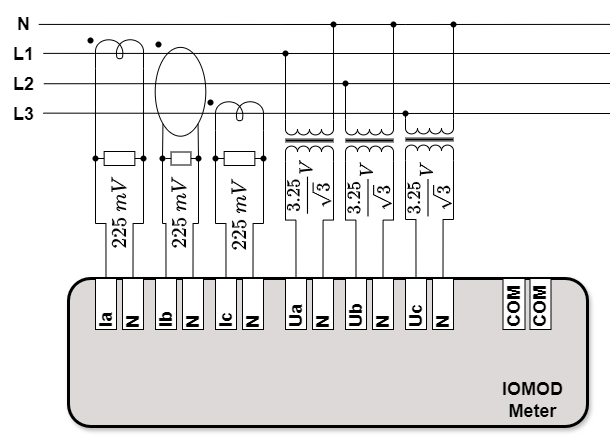

4.1.3 3 Low-Power Voltage Sensor, 2 Phase Current, and Core Balance Current Transformer

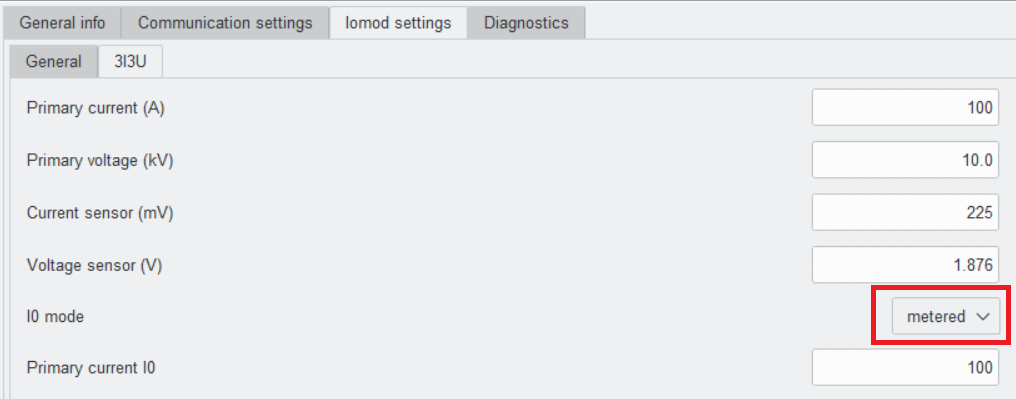

IOMod Meter allows direct measurement of the neutral current. To use this feature, I0 current acquiring mode needs to be switched in IOMod Utility from calculated to metered (Fig. 4.1.3.1).

Fig. 4.1.3.1. IOMod Utility 3I3U settings view with I0 mode switched to metered

After enabling I0 metered mode IOMod Meter second phase input (Ib+/N) becomes neutral current input. Since neutral current measurements are performed directly instead of being calculated, it allows to achieve much higher precision and sensitivity. While neutral current is being metered directly, the second phase measurements are calculated by taking a vector sum of the measured currents. In the scheme below (Fig. 4.1.3.2), current and voltage measurements are taken by using low-power current and low-power voltage sensors. The second input (Ib+/N) is connected to a low-power current sensor, which is placed on the neutral line.

Fig. 4.1.3.2. IOMod Meter I0 metered mode connection diagram

4.1.4 2-Phase Current and Core Balance Current Transformer for two feeders

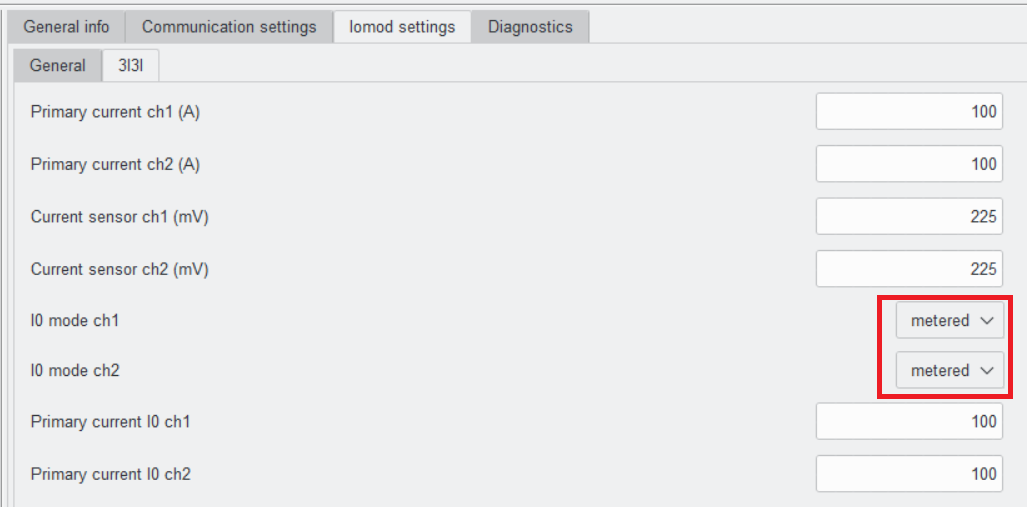

IOMod Meter operating in I0 metered mode preserves the ability of monitoring the currents of two feeders (Fig. 4.1.4.1). In this case, 3I3I connection mode needs to be enabled in IOMod Utility (Fig. 4.1.4.2). 3I3I connection mode allows using voltage inputs as second channel current inputs.

Fig. 4.1.4.1. IOMod Meter connection diagram for two feeders

with both channels I0 metered mode

In the connection scheme above (Fig. 4.1.4.1), IOMod Meter current inputs are connected to the pair of feeders via low-power current sensors. Moreover, in IOMod Utility I0 mode of both current input channels needs to be changed from calculated to metered (Fig. 4.1.4.2).

Fig. 4.1.4.2. IOMod Utility 3I3I settings view with I0 mode of both channels set to metered.

4.1.5 Conventional Current transformers (CT) connection via CT adapters.

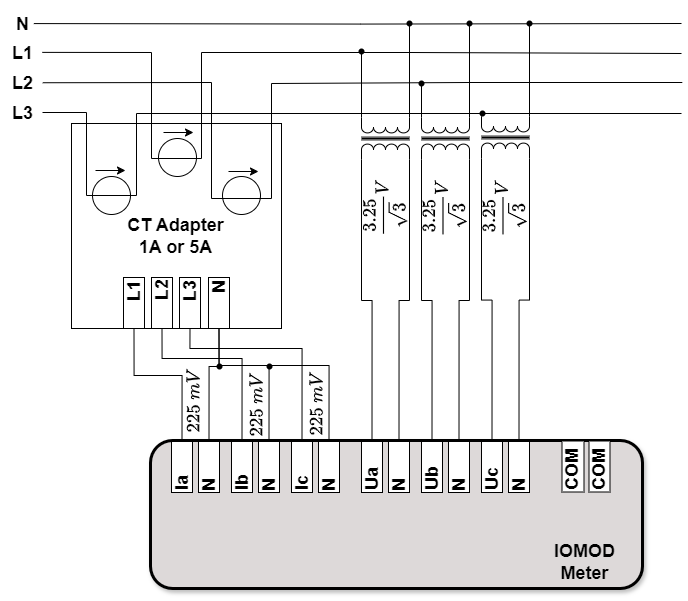

IOMod Meter can take current measurements via a current transformer adapter (Fig. 4.1.5.1). Contrary to the current sensors, current transformers are usually intended for transforming priorly lowered currents from secondary distribution networks.

Fig. 4.1.5.1. IOMod Meter connection diagram with current transformer adapter

and low-power voltage sensors

4.1.6 Conventional Voltage transformers (VT) connection via VT adapters.

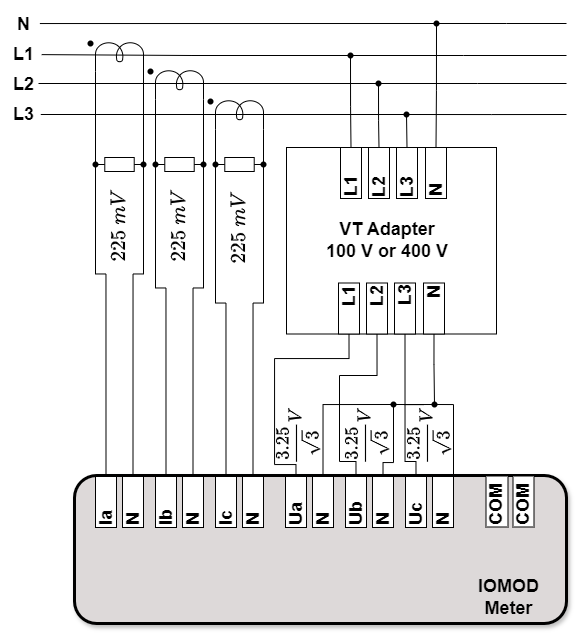

IOMod Meter can take voltage measurements via a voltage transformer adapter (Fig. 4.1.6.1). Contrary to the voltage sensors, voltage transformers are usually intended for transforming priorly lowered voltages from secondary distribution networks.

Fig. 4.1.6.1. IOMod Meter connection diagram with low-power current sensors

and voltage transformer adapter

4.2 RS485 Interface

IOMod Meter has an integrated 120 Ω termination resistor, which can be enabled or disabled via the configuration terminal. It is recommended that termination be used at each end of the RS-485 cable. IOMod Meter has a 1/8 Unit load receiver, allowing up to 255 units on a single line (compared to the standard 32 units). To reduce reflections, keep the stubs (cable distance from the main RS485 bus line) as short as possible.

4.3 Power Supply

IOMod Meter need to be powered by a 9–33 V power source. IOMOD Meter power supply inputs are located next to RS485 interface inputs (Fig. 4.3.1).

Fig. 4.3.1. Power supply inputs physical location

4.4 USB Connection

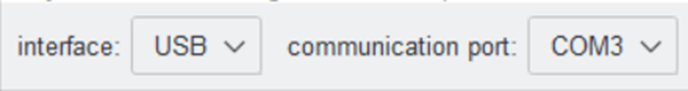

IOMod Meter device has a USB mini connection port. Its primary function is the physical connection establishment between the IOMod and a PC. By selecting the USB interface and correct communication port in IOMod Utility (Fig. 4.4.1), a user can connect to the IOMod to control its parameters and monitor its measured data and the status of fault detection functions. Also, this connection can be used for powering the module.

Fig. 4.4.1. IOMOD Utility interface and communication port parameters

Fig. 4.4.2. IOMOD Meter USB connection port physical location

5. Parametrization

In this section, the IOMod Meter settings configuration is described. IOMod Meter configuration is performed via IOMod Utility (the manual can be accessed here). All IOMod-related settings can be found in the "Iomod settings" tab (Fig. 5.1).

![]()

Fig. 5.1. IOMod settings tab

5.1 General Parameters

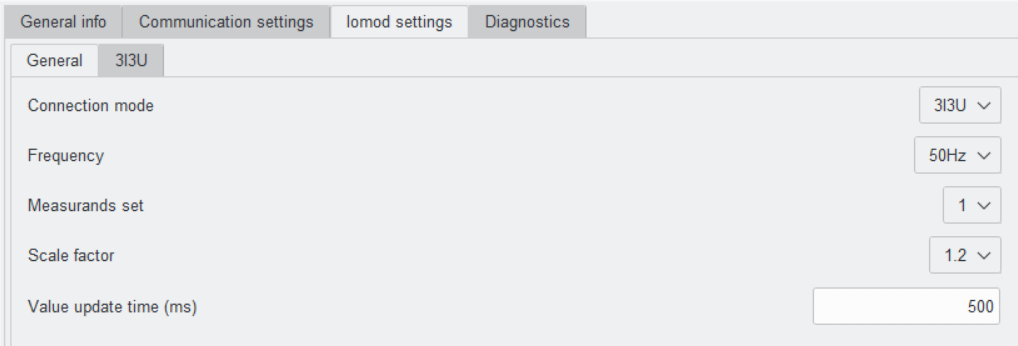

To configure IOMod Meter general settings, open the "Iomod settings" tab in IOMod Utility. After clicking on "Iomod settings", the "General" section opens (Fig. 5.1.1).

Fig. 5.1.1. IOMod Utility with IOMod Meter general settings window opened.

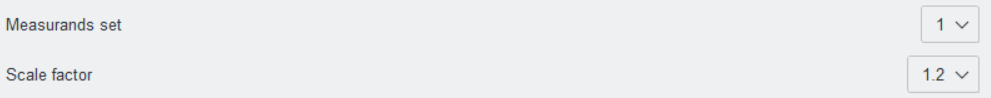

The general settings consist of two parameters, which apply to all communication protocols (Table 5.1.1). "Measurands set" and "Scale factor" are defined only in the context of the IEC 60870-5-103 communication protocol. The last parameter, "Value update time (ms)", is defined only in the context of IEC 60870-5-101 and IEC 60870-5-103 communication protocols.

Table 5.1.1. IOMOD Meter general parameter ranges and default values.

|

Parameter |

Range |

Default value |

|

Connection mode |

3I3I, 3I3U |

3I3U |

|

Frequency |

50 Hz, 60 Hz |

50 Hz |

|

Value update time (ms) * |

20-60000 |

500 |

|

Measurands set ** |

1-4 |

1 |

|

Scale factor ** |

1.2, 1.4 |

1.2 |

*The parameter is defined only for IEC 60870-5-101 and IEC 60870-5-103 communication protocols.

** The parameters are defined only for the IEC 60870-5-103 communication protocol.

The first parameter "Connection mode" allows us to define how the values measured with voltage inputs (terminals 7–12, see Fig. 2.2.1) are supposed to be interpreted. The values are interpreted as voltage measurements by default. This connection mode is denoted by the 3I3U designation. 3I3U designation means "3 currents and 3 voltages", meaning that both current and voltage measurements are being taken from a feeder. 3I3U connection mode parameters can be found in a separate settings section, which is labelled with the communication mode designation (connection mode settings are described in the next section).

Selecting 3I3I connection mode in IOMod Utility changes IOMod Setting sections – 3I3U changes to 3I3I. IOMod Meter, in 3I3I connection mode, interprets the values measured with voltage inputs (terminals 7–12, see Fig. 2.2.1) as current measurements. 3I3I designation means – "3 currents and 3 currents", meaning that the voltage inputs become the second channel current inputs. The 3I3I settings section allows us to modify connection mode parameters (described in the next section).

The "Frequency" parameter allows us to set the nominal frequency of the power line to which the IOMod Meter is connected.

If the IEC 60870-5-103 communication protocol is selected, the "Measurands set" parameter sets one of the lists of measurements (Table 6.3.2, Table 6.3.3), which is going to be sent to a master device.

If the IEC 60870-5-103 communication protocol is selected, the "Scale factor" parameter sets a value by which all measurements are going to be multiplied.

The value update time (ms) parameter defines how frequently the updated values are going to be sent to a controlling station via IEC 60870-5-101 or IEC 60870-5-103 communication protocols.

5.2 Connection mode settings

As was described earlier IOMod Meter supports two connection modes – 3I3U and 3I3I. After selecting one of them in General settings (Fig. 5.1.1), a new respectively named section appears. In this subsection, the parameters of a specific connection mode are going to be described.

5.2.1 3I3U connection mode parameters

The 3I3U connection mode parameters section has six parameters (Table 5.2), which are going to be described below.

Table 5.2.1.1 3I3U connection mode parameters.

|

Parameter |

Range |

Default value |

|

Primary current (A) |

1–2000 |

100 |

|

Primary voltage (kV) |

0.2–60.0 |

10.0 |

|

Current sensor (mV) |

100–300 |

225 |

|

Voltage sensor (V) |

1.0–3.0 |

1.876 |

|

I0 mode |

Calculated, Metered |

Calculated |

|

Primary current I0 |

1–2000 |

100 |

- The "Primary current (A)" parameter defines the nominal input current of a current sensor or a current transformer.

- The "Primary voltage (kV)" parameter sets the nominal input line voltage of a voltage sensor or a voltage transformer. If instead of the line voltage, the sensor or adapter converts the phase voltage, still, the value of the line voltage must be used. For example, if a voltage sensor declares the primary voltage of 10/√3 kV, then 10 kV must be used for the "Primary voltage (kV)" parameter, for it is the line voltage of the network.

- The "Current sensor (mV)" parameter defines the nominal output voltage of a current sensor or a current transformer.

- The "Voltage sensor (V)" parameter defines the nominal output phase voltage of a voltage sensor or a voltage transformer. Contrary to the Primary Voltage, the phase voltage must be used for this parameter. For example, if a voltage sensor declares the secondary voltage of 3.25/√3 V, then the approximate phase voltage value must be used. It means, that the given expression must be evaluated (3.25/√3 ≈ 1.876 V) and the result must be entered into the "Voltage sensor (V)" parameter (1.876 V).

- The "I0 mode" parameter defines the way of obtaining the neutral current values. The default parameter value is "Calculated", meaning that the value of the neutral current is going to be calculated by taking the phase current measurements. If "Metered" is selected, then the neutral current values are expected to be measured directly.

- The "Primary current I0" parameter defines the nominal input neutral current which is being measured by a Core Balance Current Transformer.

5.2.2 3I3I connection mode parameters

The 3I3I connection mode parameters section has eight parameters (Table 5.3), which are going to be described below.

Table 5.2.2.1 3I3I connection mode parameters.

|

Parameter |

Range |

Default value |

|

Primary current ch1 (A) |

1–2000 |

100 |

|

Primary current ch2 (A) |

1–2000 |

100 |

|

Current sensor ch1 (mV) |

100–300 |

225 |

|

Current sensor ch2 (mV) |

100–300 |

225 |

|

I0 mode ch1 |

Calculated, Metered |

Calculated |

|

I0 mode ch2 |

Calculated, Metered |

Calculated |

|

Primary current I0 ch1 |

1–2000 |

100 |

|

Primary current I0 ch2 |

1–2000 |

100 |

- The "Primary current ch1 (A)" parameter sets the nominal input current of a current sensor or a current transformer which is connected to the first channel current inputs.

- The "Primary current ch2 (A)" parameter sets the nominal input current of a current sensor or a current transformer which is connected to the second channel current inputs.

- The "Current sensor ch1 (mV)" parameter defines the nominal output voltage of a current sensor or a current transformer which is connected to the first channel current inputs.

- The "Current sensor ch2 (mV)" parameter defines the nominal output voltage of a current sensor or a current transformer which is connected to the second channel current inputs.

- The "I0 mode ch1" parameter defines the way of obtaining the neutral current values with the first channel current inputs. The default parameter value is "Calculated", meaning that the value of the neutral current is going to be calculated by taking the phase current measurements. If "Metered" is selected, then the neutral current values are expected to be measured directly.

- The "I0 mode ch2" parameter defines the way of obtaining the neutral current values with the second channel current inputs. The default parameter value is "Calculated", meaning that the value of the neutral current is going to be calculated by taking the phase current measurements. If "Metered" is selected, then the neutral current values are expected to be measured directly.

- The "Primary current I0 ch1" parameter defines the nominal input neutral current which is being measured by a Core Balance Current Transformer connected to the first channel current inputs.

- The "Primary current I0 ch2" parameter defines the nominal input neutral current which is being measured by a Core Balance Current Transformer connected to the second channel current inputs.

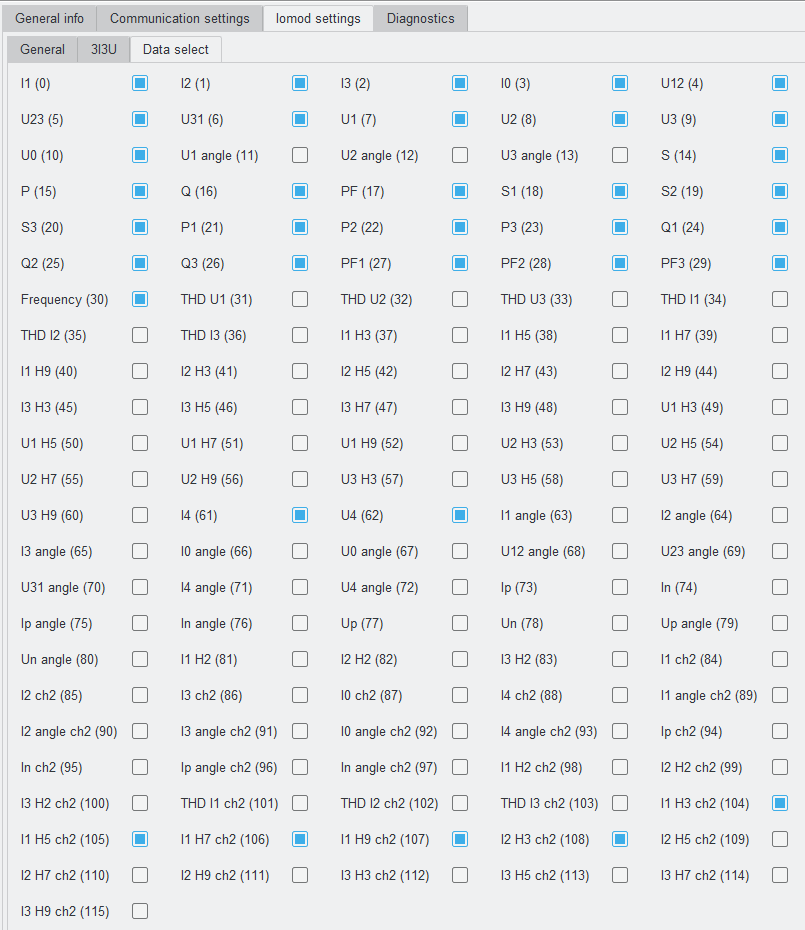

5.3 Data Select

The data select tab (Fig. 5.3.1) is the last IOMod settings section, which provides a way to control the data being sent via the IEC 60870-5-101 communication protocol. The IOA (Information Object Address) of each data unit is specified in the brackets to the right of a parameter's name. To include a parameter to a set of parameters which are sent via IEC 60870-5-101 communication protocol a checkbox to the right of a parameter's name needs to be checked.

Fig. 5.3.1. IOMOD Meter Data select tab view

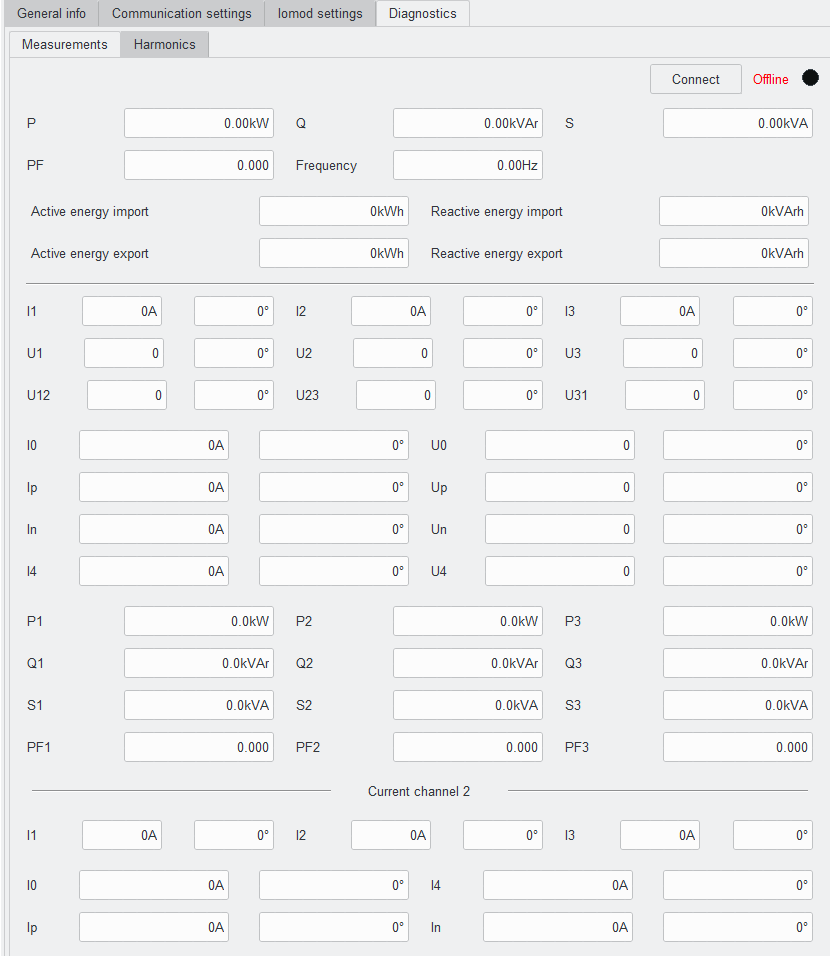

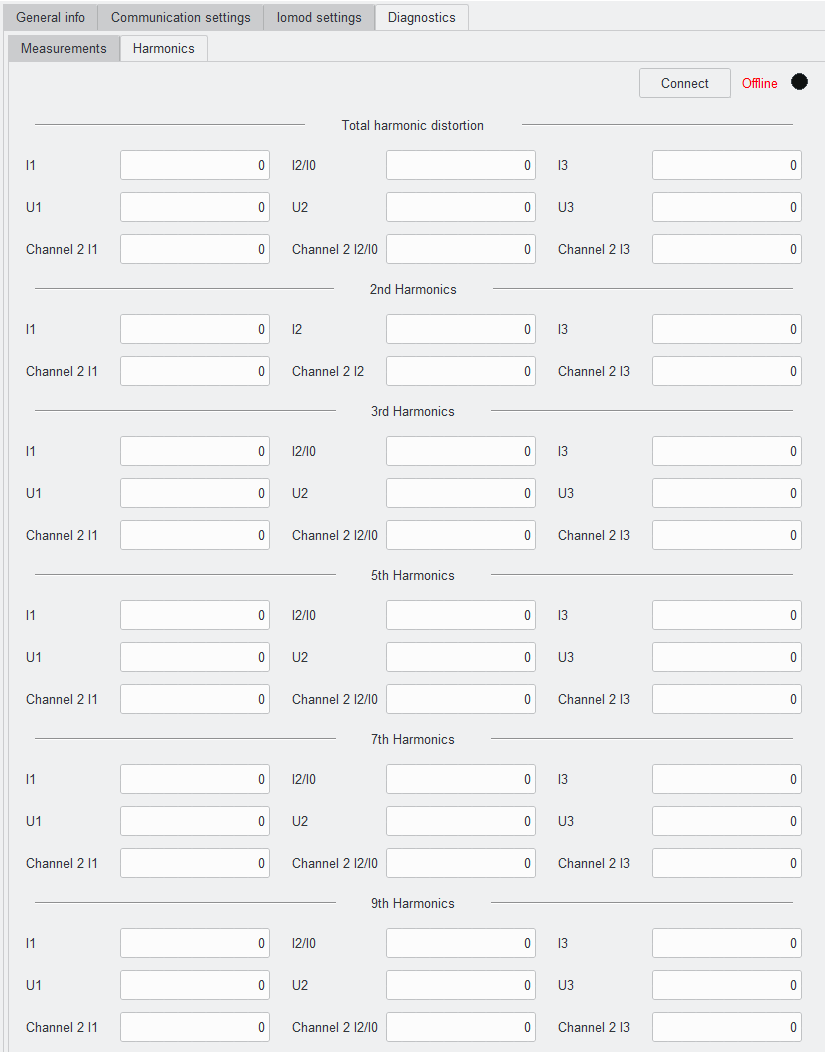

5.4 Diagnostics

The IOMod Utility Diagnostics tab allows real-time monitoring of IOMod Meter measurements and harmonics statuses. The diagnostics mode of both measurements and harmonics is turned off by default. This is indicated by the red "Offline" word designation and by the unchanging black circle (Fig. 5.4.1, Fig. 5.4.2).

Fig. 5.4.1. IOMod Utility Diagnostics tab, Measurements section in offline mode

Fig. 5.4.2 IOMod Utility Diagnostics tab Harmonics section in offline mode

To turn on real-time monitoring of both Diagnostics sections, the "Connect" button to the left of the "Offline" word designation needs to be pressed. The button can be pressed in either the Diagnostics sections (Measurements or Harmonics). After pressing the "Connect" button, the word designation of Diagnostics mode changes to "Online", the black circle starts blinking, and the button name changes to "Disconnect".

It is advisable to turn off Diagnostics mode before setting new IOMod Meter parameters. To turn off Diagnostics real-time monitoring mode, the "Disconnect" button needs to be pressed.

6. Communication Protocols

IOMod Meter supports three communication protocols: Modbus RTU, IEC 60870-5-101 and IEC 60870-5-103. Using these communication protocols, a user via a master device can read the measured data from the device. The communication protocol can be selected using the IOMod Utility (the IOMod Utility manual can be accessed here).

6.1 Modbus RTU operational information

When the Modbus RTU protocol is selected IOMod Meter acts as a slave device and waits for requests from the Modbus master. For reading the measurements, a master can send a Read Input Register (FC 04) request. A request with an unsupported function code or register number out of range will be answered with the corresponding exception. Measurement results in nominal values have an integer type, while results in primary values are 32-bit float type.

Table 6.1.1 Nominal values in integer format. The data can be read using a Modbus FC4 request.

|

Address (Dec) |

Description |

Units |

Data type |

Access |

|

0 |

Phase L1 current |

% x10 |

UINT16 |

R |

|

1 |

Phase L2 current |

% x10 |

UINT16 |

R |

|

2 |

Phase L3 current |

% x10 |

UINT16 |

R |

|

3 |

Calculated neutral current |

% x10 |

UINT16 |

R |

|

4 |

Calculated line voltage U12 |

% x10 |

UINT16 |

R |

|

5 |

Calculated line voltage U23 |

% x10 |

UINT16 |

R |

|

6 |

Calculated line voltage U31 |

% x10 |

UINT16 |

R |

|

7 |

Calculated zero sequence voltage |

% x10 |

UINT16 |

R |

|

8 |

Total 3-phase apparent power (S1+S2+S3) |

% x10 |

UINT16 |

R |

|

9 |

Total 3-phase active power (P1+P2+P3) |

% x10 |

INT16 |

R |

|

10 |

Total 3-phase reactive power (Q1+Q2+Q3) |

% x10 |

INT16 |

R |

|

11 |

Total 3-phase power factor |

x1000 |

INT16 |

R |

|

12 |

Total harmonic distortions of U1 voltage |

UINT16 |

R |

|

|

13 |

Total harmonic distortions of U2 voltage |

UINT16 |

R |

|

|

14 |

Total harmonic distortions of U3 voltage |

UINT16 |

R |

|

|

15 |

Total harmonic distortions of I1 current |

UINT16 |

R |

|

|

16 |

Total harmonic distortions of I2 current |

UINT16 |

R |

|

|

17 |

Total harmonic distortions of I3 current |

UINT16 |

R |

|

|

18 |

3rd harmonic level of the I1 current |

% |

UINT16 |

R |

|

19 |

5th harmonic level of I1 current |

% |

UINT16 |

R |

|

20 |

7th harmonic level of I1 current |

% |

UINT16 |

R |

|

21 |

9th harmonic level of I1 current |

% |

UINT16 |

R |

|

22 |

3rd harmonic level of the I2 current |

% |

UINT16 |

R |

|

23 |

5th harmonic level of I2 current |

% |

UINT16 |

R |

|

24 |

7th harmonic level of I2 current |

% |

UINT16 |

R |

|

25 |

9th harmonic level of I2 current |

% |

UINT16 |

R |

|

26 |

3rd harmonic level of the I3 current |

% |

UINT16 |

R |

|

27 |

5th harmonic level of I3 current |

% |

UINT16 |

R |

|

28 |

7th harmonic level of I3 current |

% |

UINT16 |

R |

|

29 |

9th harmonic level of I3 current |

% |

UINT16 |

R |

|

30 |

3rd harmonic level of U1 voltage |

% |

UINT16 |

R |

|

31 |

5th harmonic level of U1 voltage |

% |

UINT16 |

R |

|

32 |

7th harmonic level of U1 voltage |

% |

UINT16 |

R |

|

33 |

9th harmonic level of U1 voltage |

% |

UINT16 |

R |

|

34 |

3rd harmonic level of U2 voltage |

% |

UINT16 |

R |

|

35 |

5th harmonic level of U2 voltage |

% |

UINT16 |

R |

|

36 |

7th harmonic level of U2 voltage |

% |

UINT16 |

R |

|

37 |

9th harmonic level of U2 voltage |

% |

UINT16 |

R |

|

38 |

3rd harmonic level of U3 voltage |

% |

UINT16 |

R |

|

39 |

5th harmonic level of U3 voltage |

% |

UINT16 |

R |

|

40 |

7th harmonic level of U3 voltage |

% |

UINT16 |

R |

|

41 |

9th harmonic level of U3 voltage |

% |

UINT16 |

R |

|

42 |

Phase L1 active power |

% x10 |

INT16 |

R |

|

43 |

Phase L2 active power |

% x10 |

INT16 |

R |

|

44 |

Phase L3 active power |

% x10 |

INT16 |

R |

|

45 |

Phase L1 reactive power |

% x10 |

INT16 |

R |

|

46 |

Phase L2 reactive power |

% x10 |

INT16 |

R |

|

47 |

Phase L3 reactive power |

% x10 |

INT16 |

R |

|

48 |

The phase angle of U1 voltage |

0.1 deg |

INT16 |

R |

|

49 |

The phase angle of U2 voltage |

0.1 deg |

INT16 |

R |

|

50 |

The phase angle of U3 voltage |

0.1 deg |

INT16 |

R |

|

51 |

Phase L1 voltage |

% x10 |

UINT16 |

R |

|

52 |

Phase L2 voltage |

% x10 |

UINT16 |

R |

|

53 |

Phase L3 voltage |

% x10 |

UINT16 |

R |

|

54 |

Frequency of phase L1 voltage |

Hz x100 |

UINT16 |

R |

|

55 |

Input I4 current |

% x10 |

UINT16 |

R |

|

56 |

Input U4 voltage |

% x10 |

UINT16 |

R |

|

57 |

S1 phase apparent power |

% x10 |

INT16 |

R |

|

58 |

S2 phase apparent power |

% x10 |

INT16 |

R |

|

59 |

S3 phase apparent power |

% x10 |

INT16 |

R |

|

60 |

L1 phase power factor |

% x10 |

INT16 |

R |

|

61 |

L2 phase power factor |

% x10 |

INT16 |

R |

|

62 |

L3 phase power factor |

% x10 |

INT16 |

R |

|

63 |

The angle of the I1 current |

0.1 deg |

INT16 |

R |

|

64 |

The angle of the I2 current |

0.1 deg |

INT16 |

R |

|

65 |

The angle of the I3 current |

0.1 deg |

INT16 |

R |

|

66 |

Line voltage U12 angle |

0.1 deg |

INT16 |

R |

|

67 |

Line voltage U23 angle |

0.1 deg |

INT16 |

R |

|

68 |

Line voltage U31 angle |

0.1 deg |

INT16 |

R |

|

69 |

Current positive sequence |

Data * 10 |

UINT16 |

% |

|

70 |

Current negative sequence |

% x10 |

UINT16 |

R |

|

71 |

Voltage positive sequence |

% x10 |

UINT16 |

R |

|

72 |

Voltage negative sequence |

% x10 |

UINT16 |

R |

|

73 |

Current I0 angle |

0.1 deg |

UINT16 |

R |

|

74 |

Current I4 angle |

0.1 deg |

UINT16 |

R |

|

75 |

Voltage U0 angle |

0.1 deg |

UINT16 |

R |

|

76 |

Voltage U4 angle |

0.1 deg |

UINT16 |

R |

|

77 |

Current Ip angle |

0.1 deg |

UINT16 |

R |

|

78 |

Current In angle |

0.1 deg |

UINT16 |

R |

|

79 |

Current Up angle |

0.1 deg |

UINT16 |

R |

|

80 |

Current Un angle |

0.1 deg |

UINT16 |

R |

|

81 |

Current I1 2nd harmonic |

% x10 |

UINT16 |

R |

|

82 |

Current I2 2nd harmonic |

% x10 |

UINT16 |

R |

|

83 |

Current I3 2nd harmonic |

% x10 |

UINT16 |

R |

|

84 |

Current I1 channel 2 |

% x10 |

UINT16 |

R |

|

85 |

Current I2 channel 2 |

% x10 |

UINT16 |

R |

|

86 |

Current I3 channel 2 |

% x10 |

UINT16 |

R |

|

87 |

Current I0 channel 2 |

% x10 |

UINT16 |

R |

|

88 |

Current I4 channel 2 |

% x10 |

UINT16 |

R |

|

89 |

Current Ip channel 2 |

% x10 |

UINT16 |

R |

|

90 |

Current In channel 2 |

% x10 |

UINT16 |

R |

|

91 |

Current I1 channel 2 angle |

0.1 deg |

UINT16 |

R |

|

92 |

Current I2 channel 2 angle |

0.1 deg |

UINT16 |

R |

|

93 |

Current I3 channel 2 angle |

0.1 deg |

UINT16 |

R |

|

94 |

Current I0 channel 2 angle |

0.1 deg |

UINT16 |

R |

|

95 |

Current I4 channel 2 angle |

0.1 deg |

UINT16 |

R |

|

96 |

Current Ip channel 2 angle |

0.1 deg |

UINT16 |

R |

|

97 |

Current In channel 2 angle |

0.1 deg |

UINT16 |

R |

|

98 |

Current I1 2nd harmonic channel 2 |

0.1 deg |

UINT16 |

R |

|

99 |

Current I2 2nd harmonic channel 2 |

0.1 deg |

UINT16 |

R |

|

100 |

Current I3 2nd harmonic channel 2 |

0.1 deg |

UINT16 |

R |

|

101 |

THD of current I1 channel 2 |

UINT16 |

R |

|

|

102 |

THD of current I2 channel 2 |

UINT16 |

R |

|

|

103 |

THD of current I3 channel 2 |

UINT16 |

R |

|

|

104 |

Current I1 3rd harmonic channel 2 |

% |

UINT16 |

R |

|

105 |

Current I1 5th harmonic channel 2 |

% |

UINT16 |

R |

|

106 |

Current I1 7th harmonic channel 2 |

% |

UINT16 |

R |

|

107 |

Current I1 9th harmonic channel 2 |

% |

UINT16 |

R |

|

108 |

Current I2 3rd harmonic channel 2 |

% |

UINT16 |

R |

|

109 |

Current I2 5th harmonic channel 2 |

% |

UINT16 |

R |

|

110 |

Current I2 7th hamonic channel 2 |

% |

UINT16 |

R |

|

111 |

Current I2 9th harmonic channel 2 |

% |

UINT16 |

R |

|

112 |

Current I3 3rd harmonic channel 2 |

% |

UINT16 |

R |

|

113 |

Current I3 5th harmonic channel 2 |

% |

UINT16 |

R |

|

114 |

Current I3 7th harmonic channel 2 |

% |

UINT16 |

R |

|

115 |

Current I3 9th harmonic channel 2 |

% |

UINT16 |

R |

|

116-117 |

Active import energy |

kWh |

UINT32 |

R |

|

118-119 |

Active export energy |

kWh |

UINT32 |

R |

|

120-121 |

Reactive import energy |

kVArh |

UINT32 |

R |

|

122-123 |

Reactive export energy |

kVArh |

UINT32 |

R |

Table 6.1.2 Primary values in float format. The data can be read using Modbus FC4.

|

Address (Dec) |

Description |

Units |

Data type |

Access |

|

200 - 201 |

Current I1 |

A |

FLOAT |

R |

|

202 - 203 |

Current I2 |

A |

FLOAT |

R |

|

204 - 205 |

Current I3 |

A |

FLOAT |

R |

|

206 - 207 |

Current I0 |

A |

FLOAT |

R |

|

208 - 209 |

Voltage U12 |

U |

FLOAT |

R |

|

210 - 211 |

Voltage U23 |

U |

FLOAT |

R |

|

212 - 213 |

Voltage U31 |

U |

FLOAT |

R |

|

214 - 215 |

Voltage U1 |

U |

FLOAT |

R |

|

216 - 217 |

Voltage U2 |

U |

FLOAT |

R |

|

218 - 219 |

Voltage U3 |

U |

FLOAT |

R |

|

220 - 221 |

Voltage U0 |

U |

FLOAT |

R |

|

222 - 223 |

Voltage U1 angle |

° |

FLOAT |

R |

|

224 - 225 |

Voltage U2 angle |

° |

FLOAT |

R |

|

226 - 227 |

Voltage U3 angle |

° |

FLOAT |

R |

|

228 - 229 |

Apparent power Σ3 phase |

VA |

FLOAT |

R |

|

230 - 231 |

Active power Σ3 phase |

W |

FLOAT |

R |

|

232 - 233 |

Reactive power Σ3 phase |

Var |

FLOAT |

R |

|

234 - 235 |

Power factor Σ3 phase |

FLOAT |

R |

|

|

236 - 237 |

Apparent power S1 |

VA |

FLOAT |

R |

|

238 - 239 |

Apparent power S2 |

VA |

FLOAT |

R |

|

240 - 241 |

Apparent power S3 |

VA |

FLOAT |

R |

|

242 - 243 |

Active power P1 |

W |

FLOAT |

R |

|

244 - 245 |

Active power P2 |

W |

FLOAT |

R |

|

246 - 247 |

Active power P3 |

W |

FLOAT |

R |

|

248 - 249 |

Reactive power Q1 |

Var |

FLOAT |

R |

|

250 - 251 |

Reactive power Q2 |

Var |

FLOAT |

R |

|

252 - 253 |

Reactive power Q3 |

Var |

FLOAT |

R |

|

254 - 255 |

Power factor PF1 |

FLOAT |

R |

|

|

256 - 257 |

Power factor PF2 |

FLOAT |

R |

|

|

258 - 259 |

Power factor PF3 |

FLOAT |

R |

|

|

260 - 261 |

Frequency |

Hz |

FLOAT |

R |

|

262 - 263 |

THD Voltage U1 |

FLOAT |

R |

|

|

264 - 265 |

THD Voltage U2 |

FLOAT |

R |

|

|

266 - 267 |

THD Voltage U3 |

FLOAT |

R |

|

|

268 - 269 |

THD Current I1 |

FLOAT |

R |

|

|

270 - 271 |

THD Current I2 |

FLOAT |

R |

|

|

272 - 273 |

THD Current I3 |

FLOAT |

R |

|

|

274 - 275 |

Current I1 3rd harmonic |

FLOAT |

R |

|

|

276 - 277 |

Current I1 5th harmonic |

FLOAT |

R |

|

|

278 - 279 |

Current I1 7th harmonic |

FLOAT |

R |

|

|

280 - 281 |

Current I1 9th harmonic |

FLOAT |

R |

|

|

282 - 283 |

Current I2 3rd harmonic |

FLOAT |

R |

|

|

284 - 285 |

Current I2 5th harmonic |

FLOAT |

R |

|

|

286 - 287 |

Current I2 7th harmonic |

FLOAT |

R |

|

|

288 - 289 |

Current I2 9th harmonic |

FLOAT |

R |

|

|

290 - 291 |

Current I3 3rd harmonic |

FLOAT |

R |

|

|

292 - 293 |

Current I3 5th harmonic |

FLOAT |

R |

|

|

294 - 295 |

Current I3 7th harmonic |

FLOAT |

R |

|

|

296 - 297 |

Current I3 9th harmonic |

FLOAT |

R |

|

|

298 - 299 |

Voltage U1 3rd harmonic |

FLOAT |

R |

|

|

300 - 301 |

Voltage U1 5th harmonic |

FLOAT |

R |

|

|

302 - 303 |

Voltage U1 7th harmonic |

FLOAT |

R |

|

|

304 - 305 |

Voltage U1 9th harmonic |

FLOAT |

R |

|

|

306 - 307 |

Voltage U2 3rd harmonic |

FLOAT |

R |

|

|

308 - 309 |

Voltage U2 5th harmonic |

FLOAT |

R |

|

|

310 - 311 |

Voltage U2 7th harmonic |

FLOAT |

R |

|

|

312 - 313 |

Voltage U2 9th harmonic |

FLOAT |

R |

|

|

314 - 315 |

Voltage U3 3rd harmonic |

FLOAT |

R |

|

|

316 - 317 |

Voltage U3 5th harmonic |

FLOAT |

R |

|

|

318 - 319 |

Voltage U3 7th harmonic |

FLOAT |

R |

|

|

320 - 321 |

Voltage U3 9th harmonic |

FLOAT |

R |

|

|

322 - 323 |

Current I4 |

A |

FLOAT |

R |

|

324 - 325 |

Voltage U4 |

U |

FLOAT |

R |

|

326 - 327 |

Current I1 angle |

° |

FLOAT |

R |

|

328 - 329 |

Current I2 angle |

° |

FLOAT |

R |

|

330 - 331 |

Current I3 angle |

° |

FLOAT |

R |

|

332 - 333 |

Current I0 angle |

° |

FLOAT |

R |

|

334 - 335 |

Voltage U0 angle |

° |

FLOAT |

R |

|

336 - 337 |

Voltage U12 angle |

° |

FLOAT |

R |

|

338 - 339 |

Voltage U23 angle |

° |

FLOAT |

R |

|

340 - 341 |

Voltage U31 angle |

° |

FLOAT |

R |

|

342 - 343 |

Current I4 angle |

° |

FLOAT |

R |

|

344 - 345 |

Voltage U4 angle |

° |

FLOAT |

R |

|

346 - 347 |

Current positive seq Ip |

A |

FLOAT |

R |

|

348 - 349 |

Current negative seq In |

A |

FLOAT |

R |

|

350 - 351 |

Current Ip angle |

° |

FLOAT |

R |

|

352 - 353 |

Current In angle |

° |

FLOAT |

R |

|

354 - 355 |

Voltage positive seq Up |

U |

FLOAT |

R |

|

356 - 357 |

Voltage negative seq Un |

U |

FLOAT |

R |

|

358 - 359 |

Voltage Up angle |

° |

FLOAT |

R |

|

360 - 361 |

Voltage Un angle |

° |

FLOAT |

R |

|

362 - 363 |

Current I1 2nd harmonic |

FLOAT |

R |

|

|

364 - 365 |

Current I2 2nd harmonic |

FLOAT |

R |

|

|

366 - 367 |

Current I3 2nd harmonic |

FLOAT |

R |

|

|

368 - 369 |

Current I1 channel 2 |

A |

FLOAT |

R |

|

370 - 371 |

Current I2 channel 2 |

A |

FLOAT |

R |

|

372 - 373 |

Current I3 channel 2 |

A |

FLOAT |

R |

|

374 - 375 |

Current I0 channel 2 |

A |

FLOAT |

R |

|

376 - 377 |

Current I4 channel 2 |

A |

FLOAT |

R |

|

378 - 379 |

Current I1 channel 2 angle |

° |

FLOAT |

R |

|

380 - 381 |

Current I2 channel 2 angle |

° |

FLOAT |

R |

|

382 - 383 |

Current I3 channel 2 angle |

° |

FLOAT |

R |

|

384 - 385 |

Current I0 channel 2 angle |

° |

FLOAT |

R |

|

386 - 387 |

Current I4 channel 2 angle |

° |

FLOAT |

R |

|

388 - 389 |

Current Ip channel 2 |

A |

FLOAT |

R |

|

390 - 391 |

Current In channel 2 |

A |

FLOAT |

R |

|

392 - 393 |

Current Ip channel 2 angle |

° |

FLOAT |

R |

|

394 - 395 |

Current In channel 2 angle |

° |

FLOAT |

R |

|

396 - 397 |

Current I1 2nd harmonic ch2 |

FLOAT |

R |

|

|

398 - 399 |

Current I2 2nd harmonic ch2 |

FLOAT |

R |

|

|

400 - 401 |

Current I3 2nd harmonic ch2 |

FLOAT |

R |

|

|

402 - 403 |

THD Current I1 ch2 |

FLOAT |

R |

|

|

404 - 405 |

THD Current I2 ch2 |

FLOAT |

R |

|

|

406 - 407 |

THD Current I3 ch2 |

FLOAT |

R |

|

|

408 - 409 |

Current I1 3rd harmonic ch2 |

FLOAT |

R |

|

|

410 - 411 |

Current I1 5th harmonic ch2 |

FLOAT |

R |

|

|

412 - 413 |

Current I1 7th harmonic ch2 |

FLOAT |

R |

|

|

414 - 415 |

Current I1 9th harmonic ch2 |

FLOAT |

R |

|

|

416 - 417 |

Current I2 3rd harmonic ch2 |

FLOAT |

R |

|

|

418 - 419 |

Current I2 5th harmonic ch2 |

FLOAT |

R |

|

|

420 - 421 |

Current I2 7th harmonic ch2 |

FLOAT |

R |

|

|

422 - 423 |

Current I2 9th harmonic ch2 |

FLOAT |

R |

|

|

424 - 425 |

Current I3 3rd harmonic ch2 |

FLOAT |

R |

|

|

426 - 427 |

Current I3 5th harmonic ch2 |

FLOAT |

R |

|

|

428 - 429 |

Current I3 7th harmonic ch2 |

FLOAT |

R |

|

|

430 - 431 |

Current I3 9th harmonic ch2 |

FLOAT |

R |

6.2 IEC 60870-5-101 operational information

IEC 60870-5-101 (IEC101) is a communication protocol designed for telecontrol applications in power systems, enabling communication between a master station and slave devices (e.g., Remote Terminal Units or RTUs). The implementation of IEC101 protocol allows for a data transfer to be initiated only by a master (unbalanced mode).

IOMod Meter via IEC101 protocol transmits various measurement signals in a standardized format. These signals are predefined in the IOMod and mapped to corresponding Information Object Addresses (IOA).

Using IOMod devices along with WCC Lite allows sending broadcast time synchronization messages to multiple IOMod devices simultaneously.

The protocol distinguishes between Type Identifiers (TI), which, according to the standard, define the format, structure and type of the data being sent. The measurement signals are assigned to two different Type Identifiers, 7 and 13.

All the measurements are represented in absolute values without any scaling and using standard units. Almost every measurement can be sent using 13 ("measured value, short floating-point number"). The measurements which are sent with TI 13 signals are not marked with timestamps. This is because these signals are not intended for spontaneous transmission upon a change, but rather are to be polled by a controlling (master) station. All energy measurements are assigned to the signals with TI 7, which stands for "bitstring of 32 bits". The necessity for other data formats for the energy measurements comes from the fact that they are saved in a 32-bit unsigned integer data type. The usage of an integer type instead of a float ensures better precision.

Table 6.2.1 List of IEC101 measurement signals

|

IOA |

Description |

Units |

TI |

|

0 |

Current I1 |

A |

13 (M_ME_NC_1) |

|

1 |

Current I2 |

A |

13 (M_ME_NC_1) |

|

2 |

Current I3 |

A |

13 (M_ME_NC_1) |

|

3 |

Current I0 |

A |

13 (M_ME_NC_1) |

|

4 |

Voltage U12 |

U |

13 (M_ME_NC_1) |

|

5 |

Voltage U23 |

U |

13 (M_ME_NC_1) |

|

6 |

Voltage U31 |

U |

13 (M_ME_NC_1) |

|

7 |

Voltage U1 |

U |

13 (M_ME_NC_1) |

|

8 |

Voltage U2 |

U |

13 (M_ME_NC_1) |

|

9 |

Voltage U3 |

U |

13 (M_ME_NC_1) |

|

10 |

Voltage U0 |

U |

13 (M_ME_NC_1) |

|

11 |

Voltage U1 angle |

° |

13 (M_ME_NC_1) |

|

12 |

Voltage U2 angle |

° |

13 (M_ME_NC_1) |

|

13 |

Voltage U3 angle |

° |

13 (M_ME_NC_1) |

|

14 |

Apparent power Σ 3-phase |

VA |

13 (M_ME_NC_1) |

|

15 |

Active power Σ 3-phase |

W |

13 (M_ME_NC_1) |

|

16 |

Reactive power Σ 3-phase |

Var |

13 (M_ME_NC_1) |

|

17 |

Power factor Σ 3-phase |

13 (M_ME_NC_1) |

|

|

18 |

Apparent power S1 |

VA |

13 (M_ME_NC_1) |

|

19 |

Apparent power S2 |

VA |

13 (M_ME_NC_1) |

|

20 |

Apparent power S3 |

VA |

13 (M_ME_NC_1) |

|

21 |

Active power P1 |

W |

13 (M_ME_NC_1) |

|

22 |

Active power P2 |

W |

13 (M_ME_NC_1) |

|

23 |

Active power P3 |

W |

13 (M_ME_NC_1) |

|

24 |

Reactive power Q1 |

Var |

13 (M_ME_NC_1) |

|

25 |

Reactive power Q2 |

Var |

13 (M_ME_NC_1) |

|

26 |

Reactive power Q3 |

Var |

13 (M_ME_NC_1) |

|

27 |

Power factor PF1 |

13 (M_ME_NC_1) |

|

|

28 |

Power factor PF2 |

13 (M_ME_NC_1) |

|

|

29 |

Power factor PF3 |

13 (M_ME_NC_1) |

|

|

30 |

Frequency |

Hz |

13 (M_ME_NC_1) |

|

31 |

THD Voltage U1 |

13 (M_ME_NC_1) |

|

|

32 |

THD Voltage U2 |

13 (M_ME_NC_1) |

|

|

33 |

THD Voltage U3 |

13 (M_ME_NC_1) |

|

|

34 |

THD Current I1 |

13 (M_ME_NC_1) |

|

|

35 |

THD Current I2 |

13 (M_ME_NC_1) |

|

|

36 |

THD Current I3 |

13 (M_ME_NC_1) |

|

|

37 |

Current I1 3rd harmonic |

13 (M_ME_NC_1) |

|

|

38 |

Current I1 5th harmonic |

13 (M_ME_NC_1) |

|

|

39 |

Current I1 7th harmonic |

13 (M_ME_NC_1) |

|

|

40 |

Current I1 9th harmonic |

13 (M_ME_NC_1) |

|

|

41 |

Current I2 3rd harmonic |

13 (M_ME_NC_1) |

|

|

42 |

Current I2 5th harmonic |

13 (M_ME_NC_1) |

|

|

43 |

Current I2 7th harmonic |

13 (M_ME_NC_1) |

|

|

44 |

Current I2 9th harmonic |

13 (M_ME_NC_1) |

|

|

45 |

Current I3 3rd harmonic |

13 (M_ME_NC_1) |

|

|

46 |

Current I3 5th harmonic |

13 (M_ME_NC_1) |

|

|

47 |

Current I3 7th harmonic |

13 (M_ME_NC_1) |

|

|

48 |

Current I3 9th harmonic |

13 (M_ME_NC_1) |

|

|

49 |

Voltage U1 3rd harmonic |

13 (M_ME_NC_1) |

|

|

50 |

Voltage U1 5th harmonic |

13 (M_ME_NC_1) |

|

|

51 |

Voltage U1 7th harmonic |

13 (M_ME_NC_1) |

|

|

52 |

Voltage U1 9th harmonic |

13 (M_ME_NC_1) |

|

|

53 |

Voltage U2 3rd harmonic |

13 (M_ME_NC_1) |

|

|

54 |

Voltage U2 5th harmonic |

13 (M_ME_NC_1) |

|

|

55 |

Voltage U2 7th harmonic |

13 (M_ME_NC_1) |

|

|

56 |

Voltage U2 9th harmonic |

13 (M_ME_NC_1) |

|

|

57 |

Voltage U3 3rd harmonic |

13 (M_ME_NC_1) |

|

|

58 |

Voltage U3 5th harmonic |

13 (M_ME_NC_1) |

|

|

59 |

Voltage U3 7th harmonic |

13 (M_ME_NC_1) |

|

|

60 |

Voltage U3 9th harmonic |

13 (M_ME_NC_1) |

|

|

61 |

Current I4 |

A |

13 (M_ME_NC_1) |

|

62 |

Voltage U4 |

U |

13 (M_ME_NC_1) |

|

63 |

Current I1 angle |

° |

13 (M_ME_NC_1) |

|

64 |

Current I2 angle |

° |

13 (M_ME_NC_1) |

|

65 |

Current I3 angle |

° |

13 (M_ME_NC_1) |

|

66 |

Current I0 angle |

° |

13 (M_ME_NC_1) |

|

67 |

Voltage U0 angle |

° |

13 (M_ME_NC_1) |

|

68 |

Voltage U12 angle |

° |

13 (M_ME_NC_1) |

|

69 |

Voltage U23 angle |

° |

13 (M_ME_NC_1) |

|

70 |

Voltage U31 angle |

° |

13 (M_ME_NC_1) |

|

71 |

Current I4 angle |

° |

13 (M_ME_NC_1) |

|

72 |

Voltage U4 angle |

° |

13 (M_ME_NC_1) |

|

73 |

Current positive seq Ip |

A |

13 (M_ME_NC_1) |

|

74 |

Current negative seq In |

A |

13 (M_ME_NC_1) |

|

75 |

Current Ip angle |

° |

13 (M_ME_NC_1) |

|

76 |

Current In angle |

° |

13 (M_ME_NC_1) |

|

77 |

Voltage positive seq Up |

U |

13 (M_ME_NC_1) |

|

78 |

Voltage negative seq Un |

U |

13 (M_ME_NC_1) |

|

79 |

Voltage Up angle |

° |

13 (M_ME_NC_1) |

|

80 |

Voltage Un angle |

° |

13 (M_ME_NC_1) |

|

81 |

Current I1 2nd harmonic |

13 (M_ME_NC_1) |

|

|

82 |

Current I2 2nd harmonic |

13 (M_ME_NC_1) |

|

|

83 |

Current I3 2nd harmonic |

13 (M_ME_NC_1) |

|

|

84 |

Current I1 channel 2 |

A |

13 (M_ME_NC_1) |

|

85 |

Current I2 channel 2 |

A |

13 (M_ME_NC_1) |

|

86 |

Current I3 channel 2 |

A |

13 (M_ME_NC_1) |

|

87 |

Current I0 channel 2 |

A |

13 (M_ME_NC_1) |

|

88 |

Current I4 channel 2 |

A |

13 (M_ME_NC_1) |

|

89 |

Current I1 channel 2 angle |

° |

13 (M_ME_NC_1) |

|

90 |

Current I2 channel 2 angle |

° |

13 (M_ME_NC_1) |

|

91 |

Current I3 channel 2 angle |

° |

13 (M_ME_NC_1) |

|

92 |

Current I0 channel 2 angle |

° |

13 (M_ME_NC_1) |

|

93 |

Current I4 channel 2 angle |

° |

13 (M_ME_NC_1) |

|

94 |

Current Ip channel 2 |

A |

13 (M_ME_NC_1) |

|

95 |

Current In channel 2 |

A |

13 (M_ME_NC_1) |

|

96 |

Current Ip channel 2 angle |

° |

13 (M_ME_NC_1) |

|

97 |

Current In channel 2 angle |

° |

13 (M_ME_NC_1) |

|

98 |

Current I1 2nd harmonic ch2 |

13 (M_ME_NC_1) |

|

|

99 |

Current I2 2nd harmonic ch2 |

13 (M_ME_NC_1) |

|

|

100 |

Current I3 2nd harmonic ch2 |

13 (M_ME_NC_1) |

|

|

101 |

THD Current I1 ch2 |

13 (M_ME_NC_1) |

|

|

102 |

THD Current I2 ch2 |

13 (M_ME_NC_1) |

|

|

103 |

THD Current I3 ch2 |

13 (M_ME_NC_1) |

|

|

104 |

Current I1 3rd harmonic ch2 |

13 (M_ME_NC_1) |

|

|

105 |

Current I1 5th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

106 |

Current I1 7th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

107 |

Current I1 9th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

108 |

Current I2 3rd harmonic ch2 |

13 (M_ME_NC_1) |

|

|

109 |

Current I2 5th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

110 |

Current I2 7th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

111 |

Current I2 9th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

112 |

Current I3 3rd harmonic ch2 |

13 (M_ME_NC_1) |

|

|

113 |

Current I3 5th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

114 |

Current I3 7th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

115 |

Current I3 9th harmonic ch2 |

13 (M_ME_NC_1) |

|

|

400 |

Active import energy |

kWh |

7 (M_BO_NA_1) |

|

401 |

Active export energy |

kWh |

7 (M_BO_NA_1) |

|

402 |

Reactive import energy |

kVArh |

7 (M_BO_NA_1) |

|

403 |

Reactive export energy |

kVArh |

7 (M_BO_NA_1) |

6.3 IEC 60870-5-103 operational information

When the IEC-60870-5-103 protocol is selected, IOMod Meter uses a standard communication scheme. Initiation, control messages, and queries are initiated by a master (controlling station), while the IOMod device (controlled station) only answers requests and sends values. The first message sent by the master should be RESET CU to restart communication. When an acknowledge (ACK) packet is sent from a slave device, a master may proceed with acquiring General Interrogation and sending Time synchronization packets.

When this initialization is complete, the master should poll the IOMod Meter with Class 1 and Class 2 requests. Class 2 is used when the master polls for cyclic data. The controlled device responds when spontaneous data exists and the master then sends a request for Class 1. The controlled station responds with a time-tagged message.

Time synchronization is critical for logging events. To synchronize time, the master sends a Time Sync command with function 0 and Cause of Transmission (COT) 8. According to the IEC 60870-5-103 protocol specification, time synchronization can be performed for multiple devices using broadcast messages. For broadcast time synchronization, the master device sends a periodic signal with a time stamp to synchronize the system time of slave devices. If synchronization fails, devices default to their local system time until they successfully resynchronize.

As IOMod Meter does not have any digital inputs, only analog ones, the general interrogation returns nothing. Values of measurements are returned cyclically as a response to Class 2 data requests.

Specific settings for the IEC 60870-5-103 protocol:

- Measurand set selection. A user can select which predefined measurand set will be transmitted to the host system. Available measurand sets are presented in Table 6.3.1.

- Scale factor. The communication protocol IEC 60870-5-103 only lets 13-bit signed values in the range of -1...+1. When an IEC 60870-5-103 measurand, for example, phase voltage, is scaled as 2.4, it means that the measurand value 1 corresponds to 2.4 multiplied by Un, the measurand value 0.5 corresponds to 1.2 multiplied by In, and so on. If the measurand value, in this case, exceeds 2.4 multiplied by Un, the IEC 60870-5-103 object value saturates at its maximum value, and an overflow flag is set in the IEC 60870-5-103 object transmission.

- Device function type. By default, IOMod has the IEC 60870-5-103 Function Type set to 253. If this Function type, for some reason, is not suitable, a user can define any other type

Table 6.3.1. Data sets for 3I3U connection mode

|

Set Nr. |

TYPE |

FUN* |

INF |

Qty of data |

Information elements (measurands) |

|

1 |

9 |

253 |

148 |

9 |

I1, I2, I3, U1, U2, U3, P, Q, f |

|

2 |

9 |

253 |

149 |

23 |

I1, I2, I3, I4, U1, U2, U3, U4, P1, P2, P3, Q1, Q2, Q3, S1, S2, S3, PF1, PF2, PF3, U12(angle), U23(angle), U13(angle) |

|

3 |

9 |

253 |

150 |

60 |

I1, I2, I3, IN, U1, U2, U3, UN, P1, P2, P3, Q1, Q2, Q3, S1, S2, S3, PF1, PF2, PF3, U12, U23, U13, f, THDU1, THDU2, THDU3, THDI1, THDI2, THDI3, I1(h2), I1(h3), I1(h5), I1(h7), I1(h9), I2(h2), I2(h3), I2(h5), I2(h7), I2(h9), I3(h2), I3(h3), I3(h5), I3(h7), I3(h9), U1(h2), U1(h3), U1(h5), U1(h7), U1(h9), U2(h2), U2(h3), U2(h5), U2(h7), U2(h9), U3(h2), U3(h3), U3(h5), U3(h7), U3(h9) |

|

4 |

9 |

253 |

151 |

54 |

I1, I2, I3, IN, U12, U23, U13, UN, S, P, Q, PF, THDU1, THDU2, THDU3, THDI1, THDI2, THDI3, I1(h3), I1(h5), I1(h7), I1(h9), I2(h3), I2(h5), I2(h7), I2(h9), I3(h3), I3(h5), I3(h7), I3(h9), U1(h3), U1(h5), U1(h7), U1(h9), U2(h3), U2(h5), U2(h7), U2(h9), U3(h3), U3(h5), U3(h7), U3(h9), P1, P2, P3, Q1, Q2, Q3, U1(angle), U2(angle), U3(angle), U1, U2, U3 |

6.3.2 Data sets for 3I3I connection mode

|

Set Nr. |

TYPE |

FUN* |

INF |

Qty of data |

Information elements (measurands) |

|

1 |

9 |

253 |

148 |

7 |

I1(ch1), I2(ch1), I3(ch1), I1(ch2), I2(ch2), I3(ch2), f |

|

2 |

9 |

253 |

149 |

8 |

I1(ch1), I2(ch1), I3(ch1), I4(ch1), I1(ch2), I2(ch2), I3(ch2), I4(ch2) |

|

3 |

9 |

253 |

150 |

45 |

I1(ch1), I2(ch1), I3(ch1), I0(ch1), I1(ch2), I2(ch2), I3(ch2), I0(ch2), f, THDI1(ch1), THDI2(ch1), THDI3(ch1), I1(h3, ch1), I1(h5, ch1), I1(h7, ch1), I1(h9, ch1), I2(h3, ch1), I2(h5, ch1), I2(h7, ch1), I2(h9, ch1), I3(h3, ch1), I3(h5, ch1), I3(h7, ch1), I3(h9, ch1), THDI1(ch2), THDI2(ch2), THDI3(ch2), I1(h3, ch2), I1(h5, ch2), I1(h7, ch2), I1(h9, ch2), I2(h3, ch2), I2(h5, ch2), I2(h7, ch2), I2(h9, ch2), I3(h3, ch2), I3(h5, ch2), I3(h7, ch2), I3(h9, ch2) |

A certain set of measurements can be configured in IOMod Utility General settings (see Table 5.1.1, Fig. 6.3.1).

Fig. 6.3.1. IOMod Utility General settings IEC 60870-5-103 protocol parameters

Type 9 signals allocate only 13 bits for measurement values, which is not enough for float values to be transferred. For that reason, all measurement data are being scaled. However, not all values are scaled the same. All currents, voltages and power measurements are scaled using the same algorithm. The range of the maximum and the minimum measurement values, which can be transferred with the IEC103 protocol, is calculated by multiplying the nominal value by the scale factor:

MMV = SF ⋅ NV (6.3.1)

- MMV – maximum measurement value;

- NV – nominal value;

- SF – scale factor;

The scale factor of most measurements can be selected in IOMod Utility General settings (Table 5.1.1, Fig. 6.3.1). The maximum measurement value (MMV) is only the upper limit of the allowed range. The full allowed range goes from -MMV up to +MMV. Since the first bit is used to denote the sign, the maximum absolute value, which can be sent via IEC 60870-5-103 communication protocol, is 212 = 4096. The MMV is mapped to this value, so that if the measured value is equal to the MMV, 4096 is going to be sent to a controlling station via IEC103 protocol. If a measurement value exceeds MMV, then the overflow is going to be indicated by the signal and 4096 is going to be sent. If a measured value is inside the allowed range, then the scaled value, which is going to be sent using the IEC103 signal, is calculated by multiplying it by 4096 and dividing it by the maximum measurement value:

SV = MV ⋅ 4096MMV, where -MMV ≤ MV ≤ +MMV (6.3.2)

- SV – scaled value, which is going to be sent using IEC103 protocol;

- MV – measured value, which must be in the allowed range;

- MMV – maximum measurement value;

In the special case where the measured value is equal to the nominal value, the scaled value formula can be simplified as:

SV = NV ⋅ 4096SF ⋅ NV = 4096SF (6.3.3)

The scaled values of other measurands are calculated by using different scaling techniques. The scaled frequency is calculated by multiplying the measured frequency by 50. All angle measurements are scaled by a factor of 10.