CLMod manual

Introduction

CL MOD is RS485 interface converter-splitter to 6X 20mA current loop interface designed to be used with power meters (SLAVE device with current loop interface) and data loggers, gateways or other equipment (MASTER device with half-duplex RS485 interface). This converter was developed to read multiple meters data over 20mA current loop interface with long distance lines up to 2km. CLMod with 6 current loop interfaces is capable to readout data up to 30 meters (5 meters per single current loop). CLMod is protocol agnostic and can be used with any type of protocol.

Features

⦁ 6X 3kVRMS isolated 20mA current loop interface;

⦁ supports up to 5 power meters on each current loop (30 meters total);

⦁ baud rates: 1200 to 9600;

⦁ 24VDC (21.6-26.4VDC full range) power supply;

⦁ automatic open loop detection and disconnection;

⦁ fail indication for each current loop;

⦁ integrated current loop protection (optional);

⦁ operating range from -40°C to +80°C;

⦁ dimensions 101x119x17.5mm.

⦁ LED indication of data transmission on every current loop interface

⦁ Compatible with Elgama Elektronika meters

⦁ RS485 interface for RTU/Datalogger

Device operational information

CL MOD connects to a MASTER device over RS485 half-duplex interface, splits and transmits MASTER requests into 6 current loop interfaces. Power meters connects to current loop interface in series (up to 5 meters on each CL interface). One power meter (SLAVE device) can transmit simultaneously, so some time delay need to be added between MASTER’s requests according to selected baud rate.

CL MOD automatically detects and disconnects open current loop (not connected or flooding) and has a status indication for each of 6 current loop interfaces. CL MOD automatically reconnects to current loop when fault is fixed.

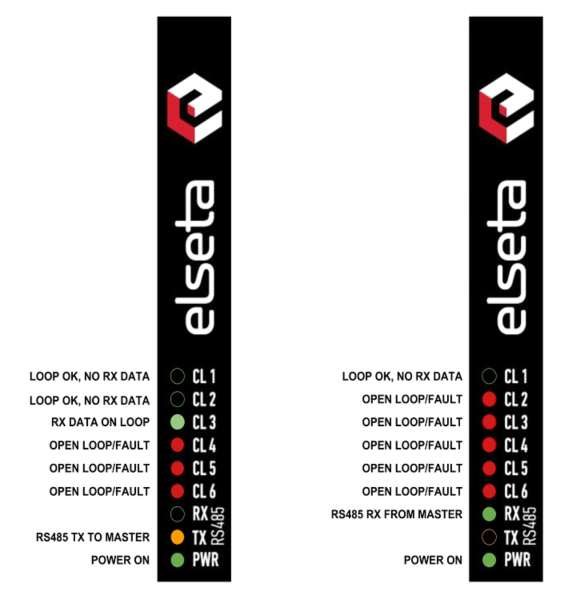

Indication examples are demonstrated on Fig 1.

Fig 1. CL MOD indication examples

Technical information

| System | ||

|

1. |

Dimension | 101 x 119 x 17.5 mm |

| 2. | Case | ABS, black |

| 3. | Working environment | Indoors |

| 4. | Working temperature | -40 ÷ +80°C |

| 5. | Recommended operating conditions | 5 – 60°C and 20 – 80% RH; |

| Electrical specifications |

||

| 6. | Power Supply | 24VDC, 4W (nominal); 21.6-26.4VDC (full range) |

| 7. | Current loop voltage | 24VDC (max) |

| 8. | Current loop IMARK | ≥12mA |

| 9. | Current loop ISPACE | ≤3mA |

| 10. | CL1-CL6 surge protection (optional) |

20kA, 8/20µs |

Device Connection

Power connection

CL MOD should be powered from a DC power supply of 24V, 4W (minimum). Power connector is shown on Fig. 5.1. Apply +24V to V+ and 0V to V-. The device has a built-in reverse voltage polarity, overcurrent and overvoltage protection.

Fig 2. Power connector

RS485 serial interface

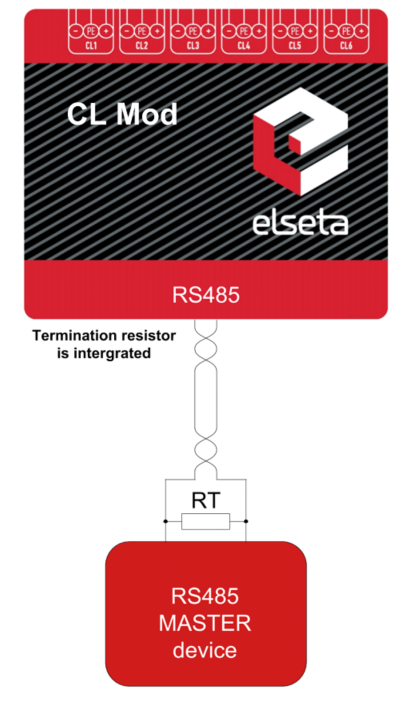

CL MOD has integrated 120Ω termination resistor. It is recommended to use termination at each end of the RS485 cable. See typical connection diagram on Fig 3.

Fig 3. RS485 connection diagram

Current loop serial interface

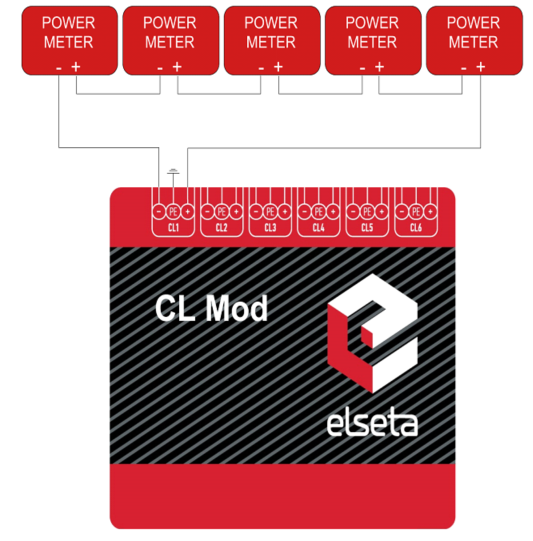

CL MOD can support up to 5 power meters on each current loop interface. Fig 4. shows an example of CL MOD current loop interface connection.

Fig 4. CL interface connection diagram

If a number of meters is > 1, it is recommended to group meters to use as little current loop interfaces as possible. This will help to reduce heat dissipation of CL MOD. For example, if 8 meters need to be connected, it is recommended to connect 4 meters to CL1 interface and 4 meters to CL2 interface (if possible).