# How To

# Connect to WCC Lite

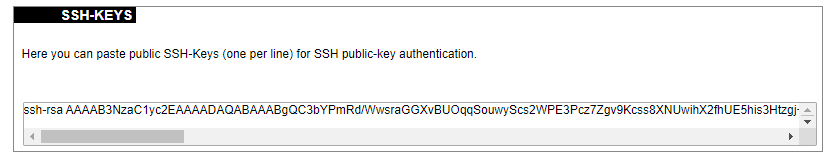

In order to connect to the WCC Lite:

1. Power up the WCC Lite

2. Once the WCC Lite boots up, plug an ethernet cable into the **ETH0** port.

3. Connect the other end of the cable to the Ethernet interface of your PC/Mac

4. Make sure DHCP is enabled on your Ethernet interface

5. Open [https://192.168.1.1](http://192.168.1.1/) in your web browser (username: root, password: wcclite)

Remember, by default WCC Lite interfaces have following designations

Interface

Designation

Specs

ETH0

LAN

DHCP server, without firewall protection by default.

ETH1

WAN

DHCP client, strict firewall rules

# WAN IP Setup

## Description

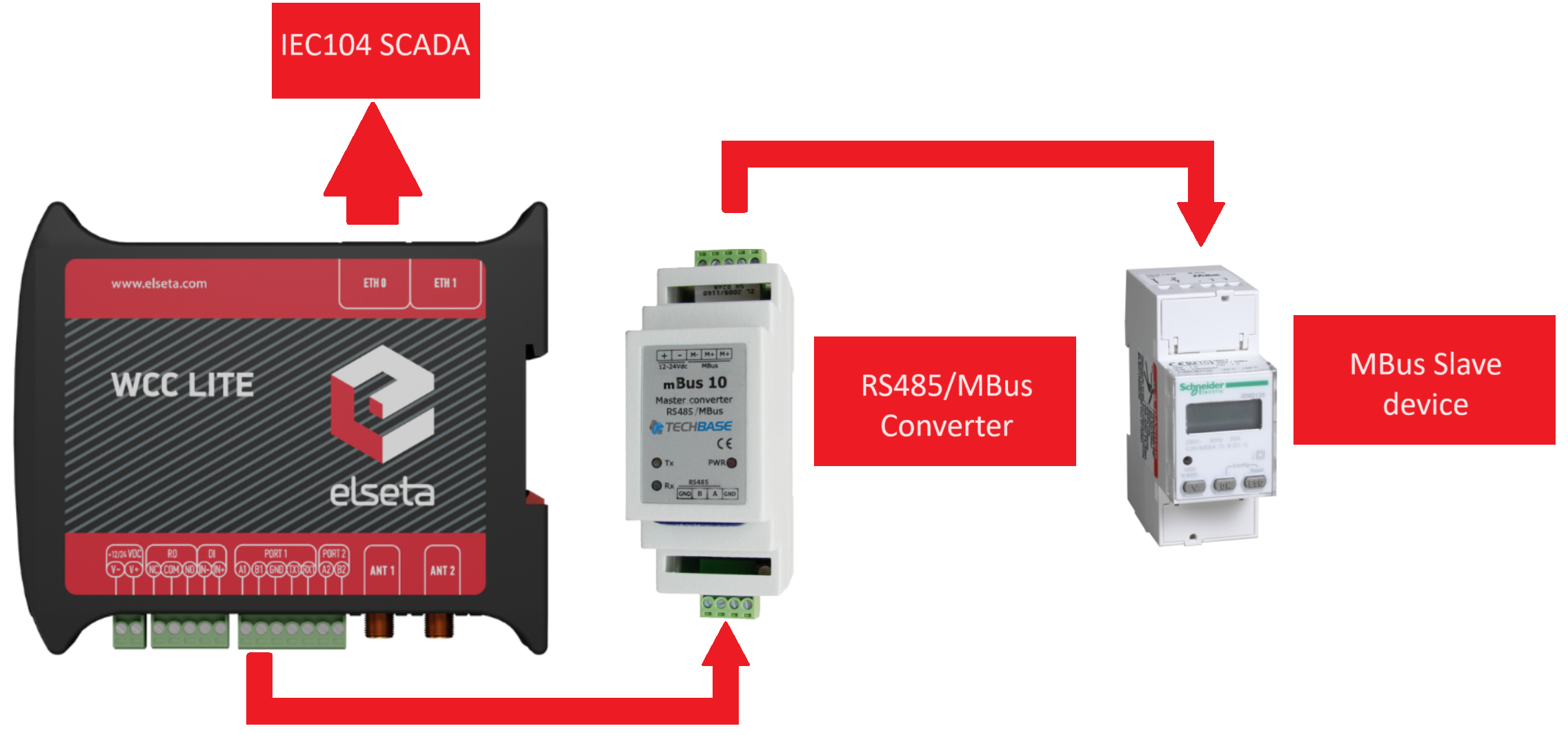

One o the first steps in RTU/Datalogger setting up is to prepare connection to internet or a specific private network over Ethernet or GSM. This article describes WAN over Ethernet connection setup.

[](https://wiki.elseta.com/uploads/images/gallery/2020-10/image-1601990457991.png)

## Setting WAN IP

1. Go to Network → Interfaces → Edit (WAN)

2. Select protocol - Static address and click on Switch protocol

3. Enter addresses of your WAN network and click on Save & Apply

Example:

Video how to setup WAN IP address:

# Enable Internet or WAN for connected devices

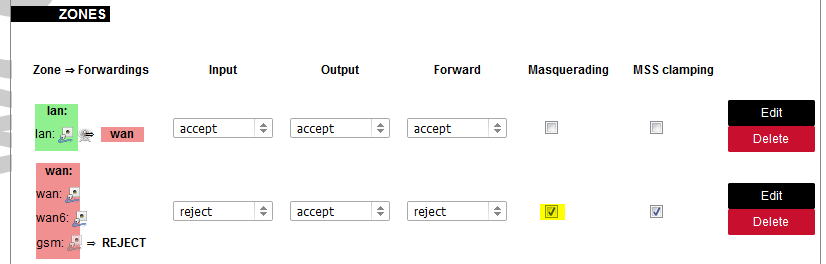

In order to enable connected devices communication through the router it is needed to enable Masquerading for outgoing packets on WAN interface:

1. Go to Network → Firewall→ General settings

2. Select Masquerading on WAN interface and click on Save & Apply

[](https://wiki.elseta.com/uploads/images/gallery/2020-10/image-1601989913581.png)

A short video about this:

# Capture packets using tcpdump

### Description

This article describes how to log packets using tcpdump.

### Installing tcpdump

Before starting, you need to install required packages. **Tcpdump** and **Libpcap**. These packages can be found attached to the article.

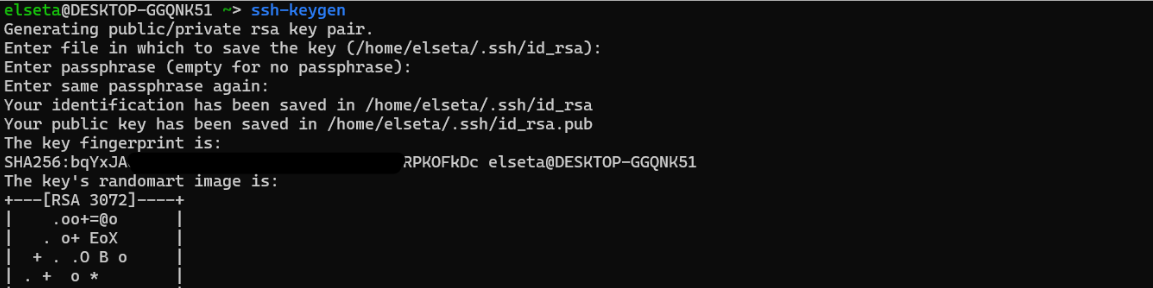

To install, you need to upload the packages to your **WCCLite** /tmp/ directory. You can achieve this by using **scp** or any other software that has scp compatibility, for example: WinSCP, PSCP, FileZilla.

We are going to upload using **scp.**

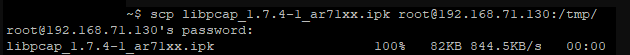

1. Navigate to the directory where **libpcap** is.

2. Open the command terminal in that directory.

3. Execute command: *scp libpcap\_1.7.4-1\_ar71xx.ipk root@192.168.1.1:/tmp/*

4. It will ask you for the password. Enter the default wcclite password - *wcclite*.

[](https://wiki.elseta.com/uploads/images/gallery/2021-08/image-1627892977493.png)

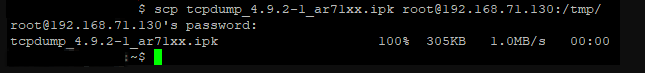

1. Navigate to the directory where **tcpdump** is.

2. Open the command terminal in that directory.

3. Execute command: *scp tcpdump\_4.9.2-1\_ar71xx.ipk root@192.168.1.1:/tmp/*

4. It will ask you for the password. Enter the default wcclite password - *wcclite*.

[](https://wiki.elseta.com/uploads/images/gallery/2021-08/image-1627893107060.png)

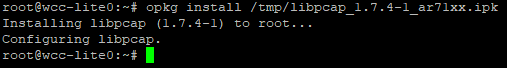

After uploading the packages, you need to install them.

1. Connect to the **WCCLite** using an ssh client. We recommend using [*putty*](https://www.chiark.greenend.org.uk/~sgtatham/putty/latest.html)

2. Execute command: *opkg install /tmp/libpcap\_1.7.4-1\_ar71xx.ipk* to install **libpcap**

3. If successful you will get this message.

[](https://wiki.elseta.com/uploads/images/gallery/2021-08/image-1627890317789.png)

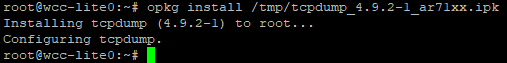

Now to install **tcpdump**:

1. Execute: *opkg install /tmp/tcpdump\_4.9.2-1\_ar71xx.ipk* to install **tcpdump.**

2. If successful you will get this message.

[](https://wiki.elseta.com/uploads/images/gallery/2021-08/image-1627890567145.png)

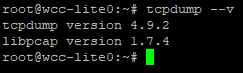

To check if everything installed correctly, execute this command: *tcpdump --v*

[](https://wiki.elseta.com/uploads/images/gallery/2021-07/image-1627654474783.png)

Now **Tcpdump** has been successfully installed.

### Running tcpdump

To run **tcpdump** you need to give it specific options. You can find all of them in the [manual](https://www.tcpdump.org/manpages/tcpdump.1.html). Here are some of the more frequent ones:

**Switch**

**Syntax**

**Description**

-i any

tcpdump -i any

Capture from all interfaces

-i eth0

tcpdump -i eth0

Capture from specific interface

-D

tcpdump -D

Show available interfaces

-w

tcpdump -i eth0 -w capture.pcap

Save capture to file (.pcap for reading it with *Wireshark* or other packet analysis tools)

-c

tcpdump -i eth0 -c 100

Capture first 100 packets and exit

-n

tcpdump -n -i eth0

Do not resolve host names

port

tcpdump -i eth0 port 2404

Capture traffic from a defined port only

host

tcpdump host 192.168.1.100

Capture packets from specific host

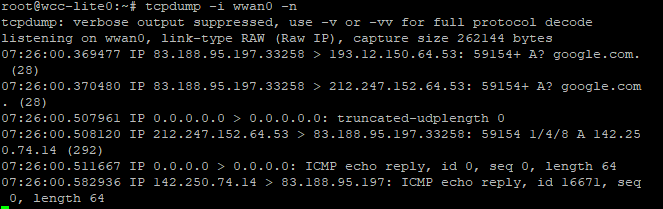

After you write your specific command you execute it via the console.

Here is shown ***tcpdump -i wwan0 -n.*** This command shows all traffic that goes through the gsm interface.

[](https://wiki.elseta.com/uploads/images/gallery/2021-08/image-1627889271177.png)

#### Examples

Capture packets that go through gsm interface and write a new file to /tmp/capture-<count>.pcap file every 3600 seconds.

tcpdump -i any -n port 2404 -w /tmp/capture-%H.pcap -G 3600

Capture packets that are on port 2404 that go through all interfaces and save a new file to /tmp/capture-<count>.pcap every 3600 seconds.

### Downloading packet files

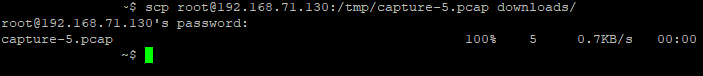

If you save your **tcpdump** files, you need to download them from the **WCCLite.** This can be achieved by using **scp** or any software that has scp compatibility, for example: WinSCP, PSCP, FileZilla.

We are going to use **scp** to download the file.

1. Open the command terminal on your computer.

2. Execute command with the location of your *packet dump* file and directory where to save it. *scp root@192.168.1.1:/<dump directory>/<dump name> <directory where to save it>*

3. It will ask for the **WCCLite** password. Enter the default password - *wcclite*.

4. If successful the file will appear in the determined location.

Example of the command.

[](https://wiki.elseta.com/uploads/images/gallery/2021-08/image-1627903702658.png "Example of the command")

### Files

1. PuTTy ssh software [Download](https://www.chiark.greenend.org.uk/~sgtatham/putty/latest.html)

2. WinSCP software [Download](https://winscp.net/eng/index.php)

3. TCPDump [manual](https://www.tcpdump.org/manpages/tcpdump.1.html)

4. Libpcap [Download](https://wiki.elseta.com/attachments/7)

5. Tcpdump [Download](https://wiki.elseta.com/attachments/8)# IOMod setup with WCC Lite

In this chapter you will learn how to connect all kinds of Elseta IOMods to the WCC Lite

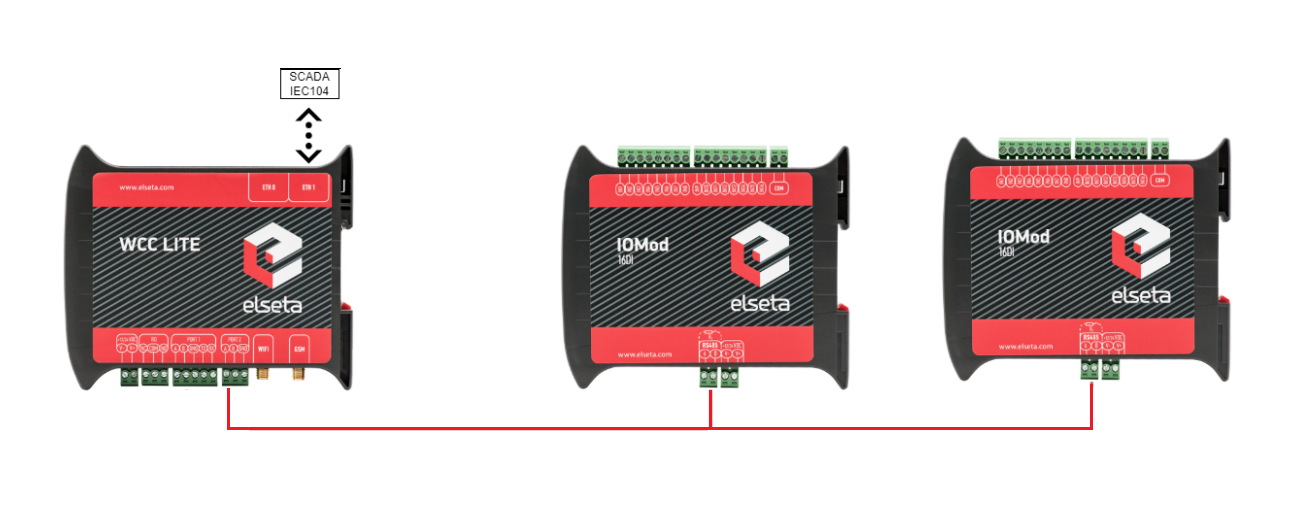

# Connecting IOMod 16DI to the WCC Lite

### Description

This article describes connecting and configuring IOMOD 16DI to the WCC Lite using IEC101, IEC103, and Modbus RTU.

[](https://wiki.elseta.com/uploads/images/gallery/2021-12/image-1638361303133.png)

Typical connection schematic for IOMod 16DI

WCC Lite can be connected to IOMod 16DI via PORT1 or PORT2.

### Preparing the configuration

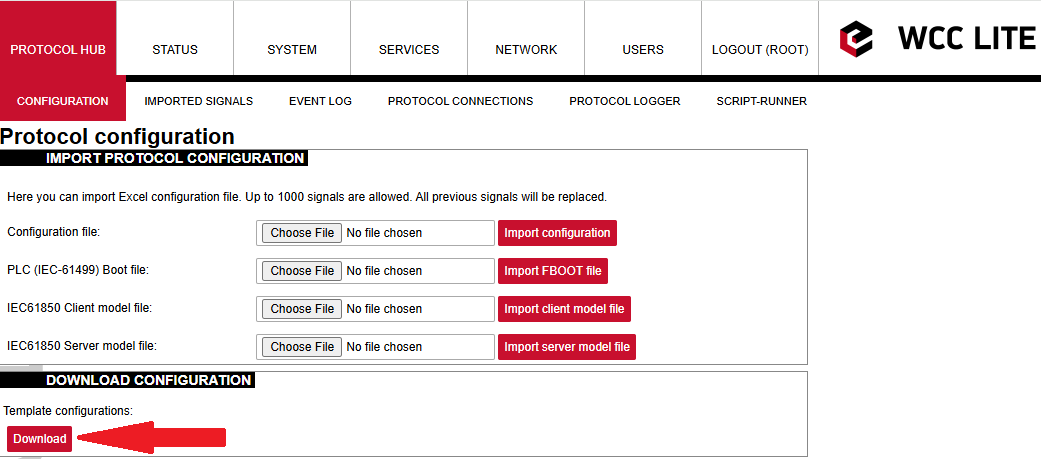

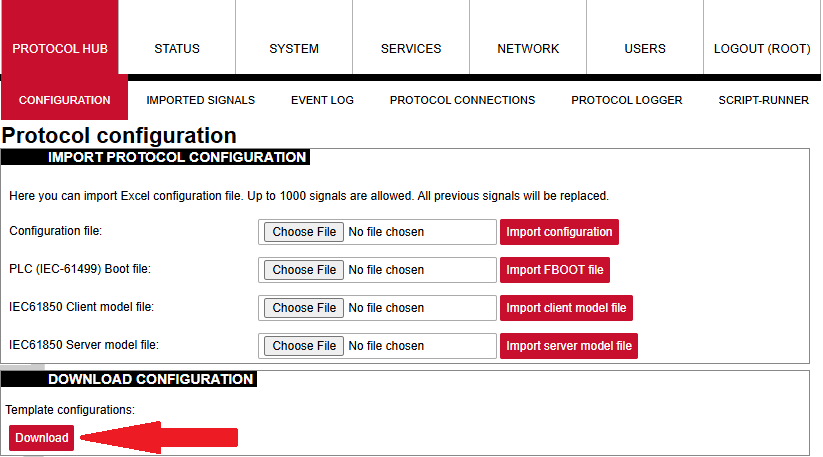

First, you need to configure WCC Lite using any spreadsheet editing program. The configuration templates can be found on the WCC Lite web: Protocol Hub --> Configuration. At the bottom of the page, there will be a *Download* button for template configurations.

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745391989421.png)

You can download the example configuration for each firmware version at the bottom of the article, or create your own using these links:

- For [IEC103 ](https://wiki.elseta.com/attachments/650)

- For [IEC101](https://wiki.elseta.com/attachments/649)

- For [Modbus](https://wiki.elseta.com/attachments/648)

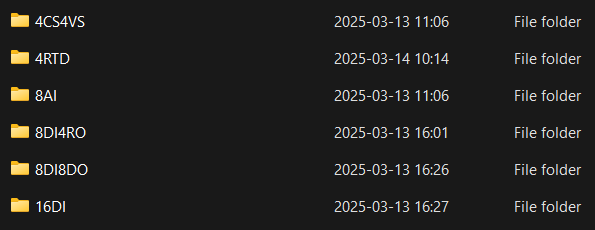

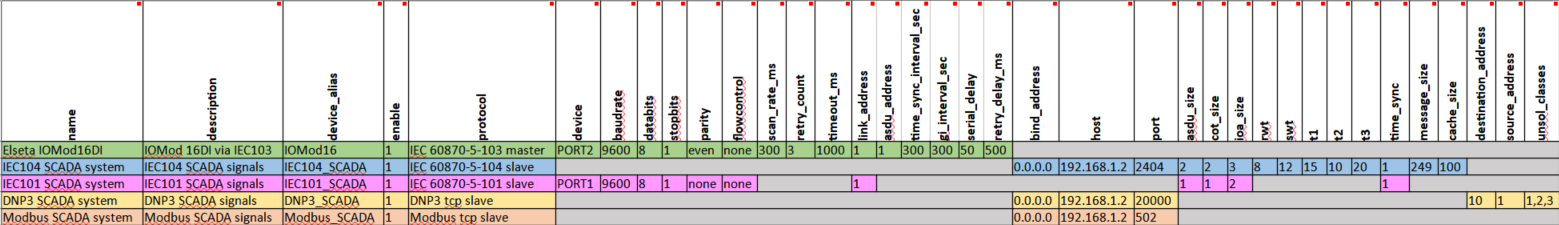

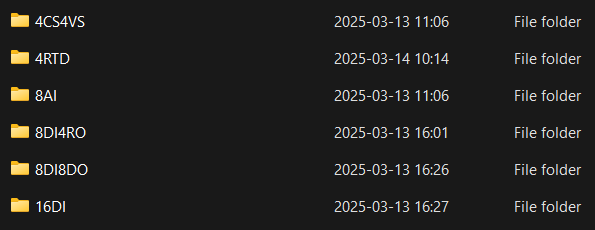

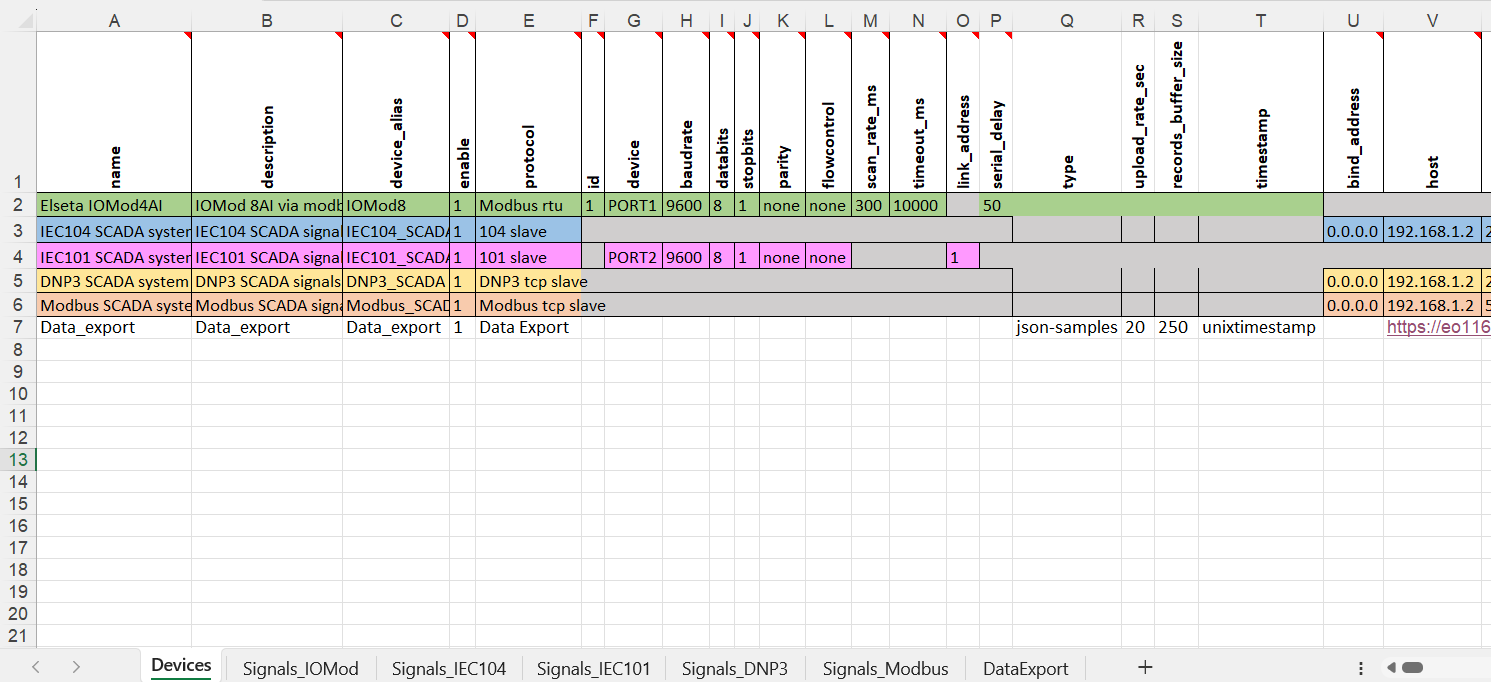

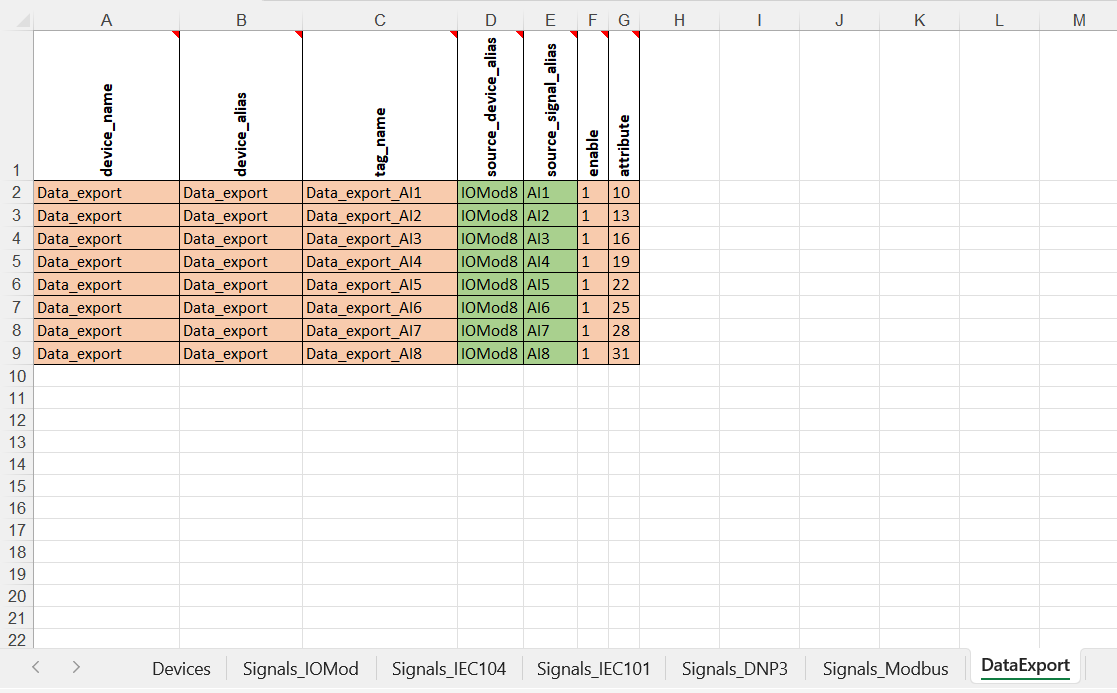

You need to configure the Devices and Signals sheets before continuing. After downloading template configurations, open the phub templates folder. You will see that there are different template folders for each IOMod:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741952060514.png)

To select the correct configuration, check the sticker on the back of the IOMod. There, you will find which protocol to use according to Factory FW type. For example, if you have IOMod 16DI with IEC103 FW, select configuration iomod\_16DI\_IEC103\_to\_IEC104\_DNP3\_Modbus\_SCADA.

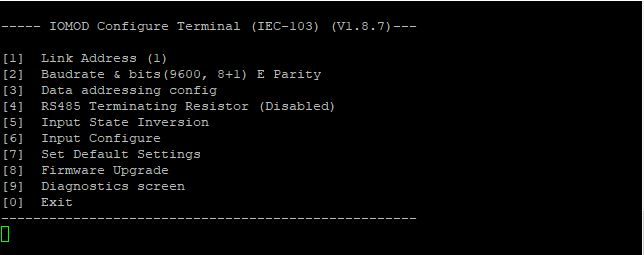

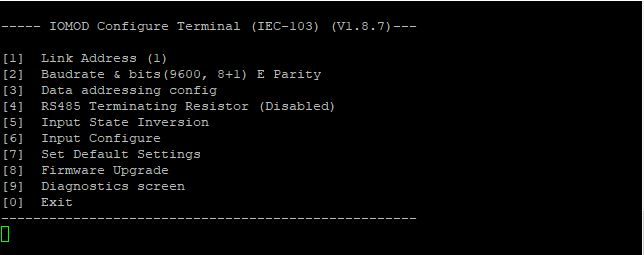

IOMOD needs to be configured, as in the Excel configuration. If templates are being used, default parameters should be set for the IOMOD. IOMODs with firmware version 1 are configured via PuTTY or other SSH programs using the USB port on the device's front panel. This can be done following the [IOMod 16DI user manual](https://wiki.elseta.com/attachments/647).

IOMOD also has a series of parameters that can be configured directly for the IOMOD without changing the WCC Lite configuration. Each IOMOD has its unique parameters, which can be seen on the configuration menu.

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745916922979.png)

A new menu opens by clicking \[6\], allowing the user to configure the 16DI inputs. Input grouping allows grouping of neighbour inputs, the first being an odd-numbered input. This then makes the grouped inputs a double-point input. When making an Excel configuration for WCC Lite with double-point information, the even-numbered input signal should be deleted, and the odd-numbered input signal should be configured as a double-point signal.

The user can also change the input filter time. This parameter is set in milliseconds and determines the time after which the input is represented with the changed state. For example, if the filter time is 1000ms, and the input has been on for 500ms, the state won't change from OFF to ON. This is relevant when seeking to avoid unnecessary data.

### Uploading configuration

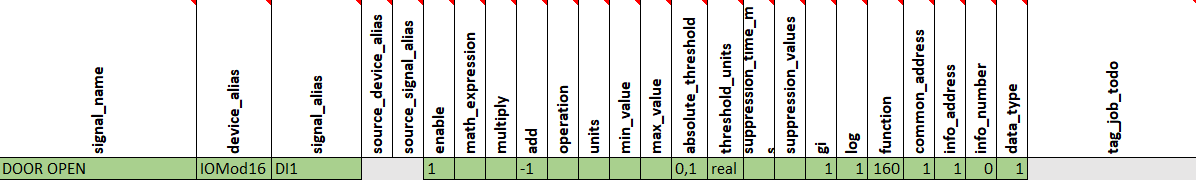

Template configurations can work with default settings without any further changes. These template configurations can also be used to configure protocols like Modbus-master and DNP3. Configuration can be modified according to the functionality needed. For that, you can rely on the examples given in the links above (Preparing the configuration). If you need to specify different IEC104 slave settings, you can do that by changing the Excel configuration. By changing settings such as *info\_address* or *data\_type,* you can adapt the IEC104 slave to work as needed. To test this example, specify your computer's IP address in the Excel configuration for the IEC104 slave.

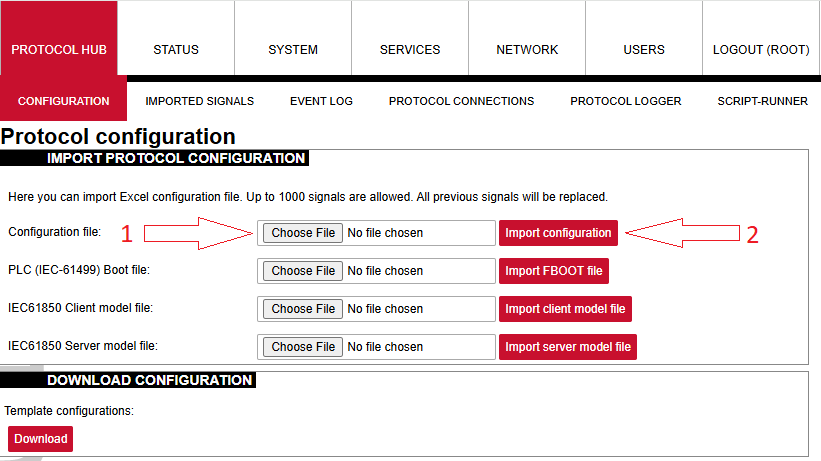

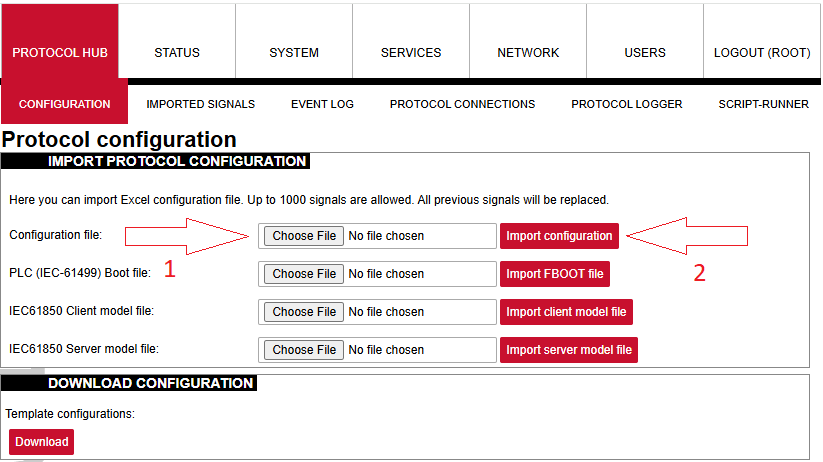

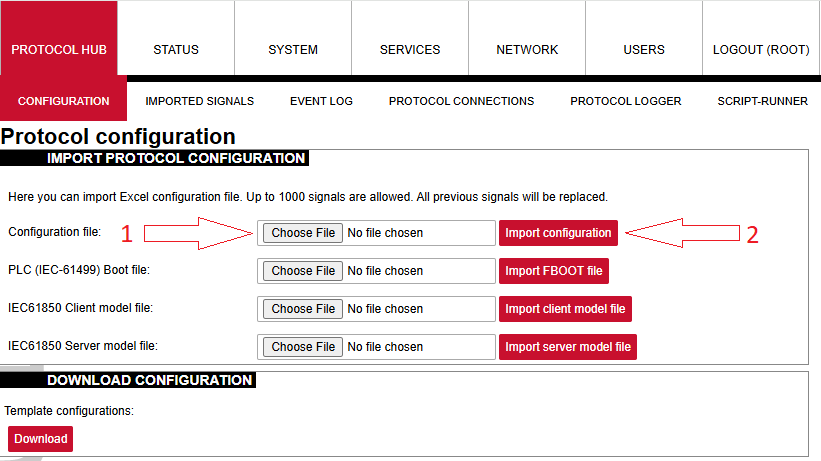

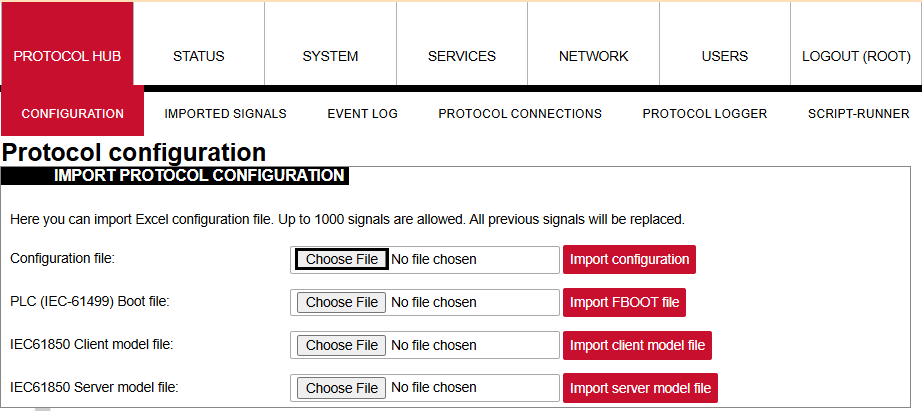

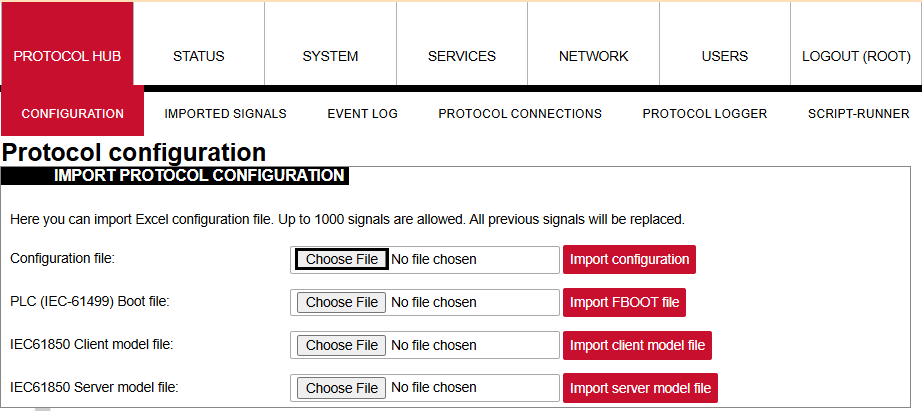

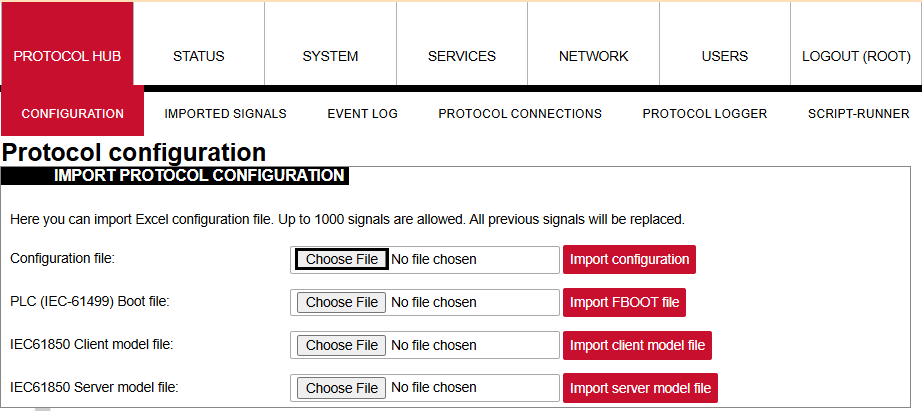

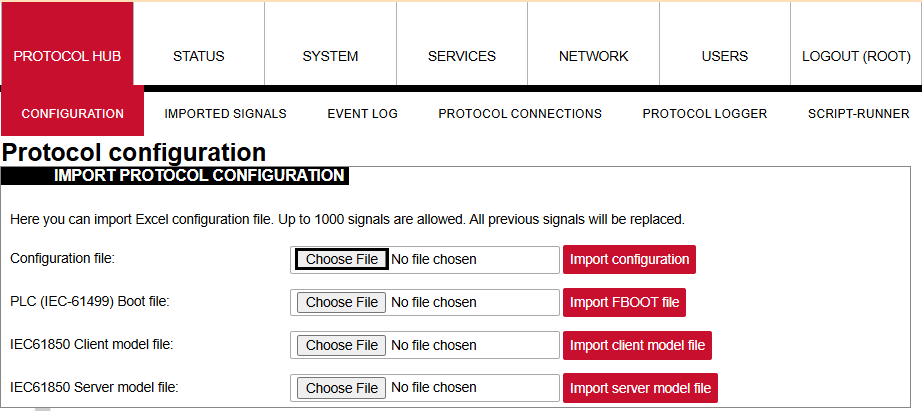

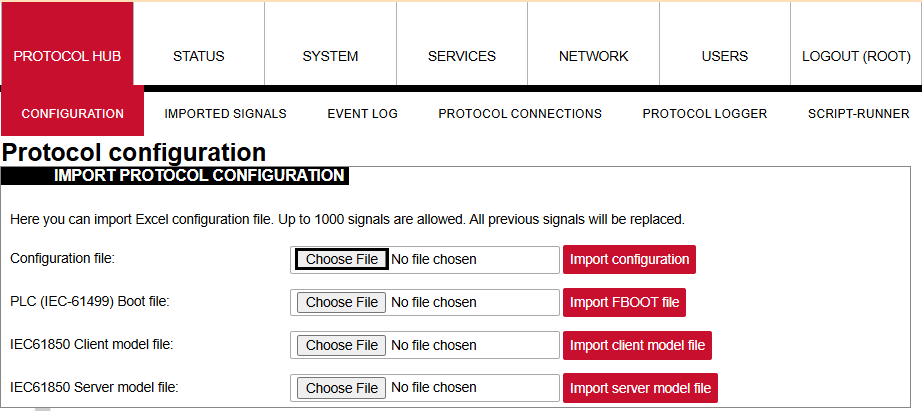

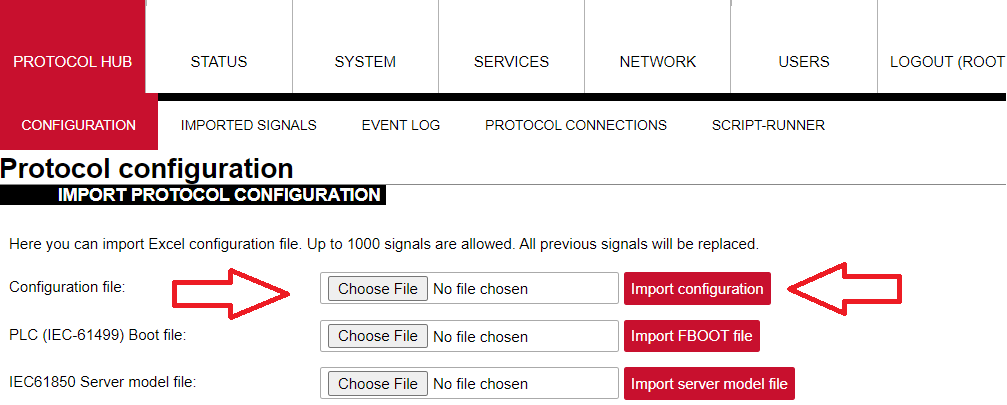

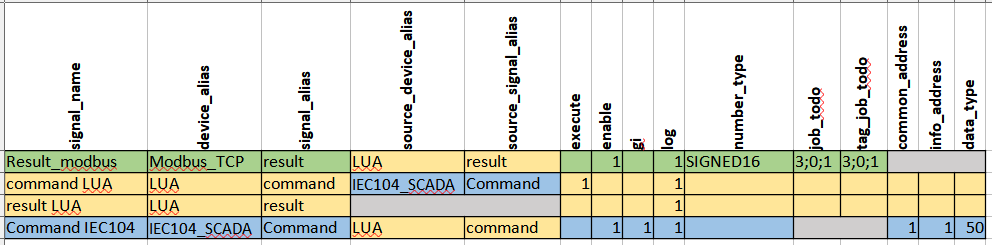

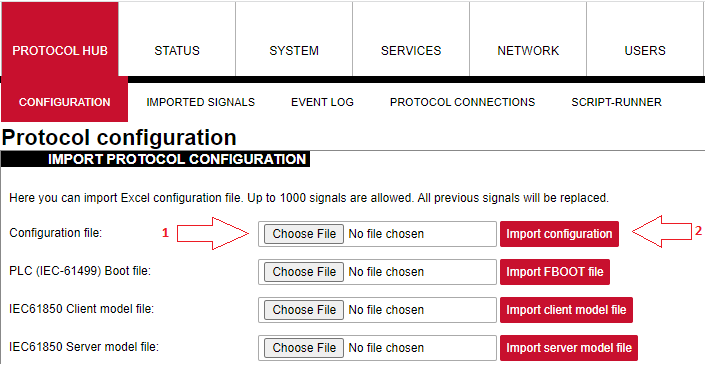

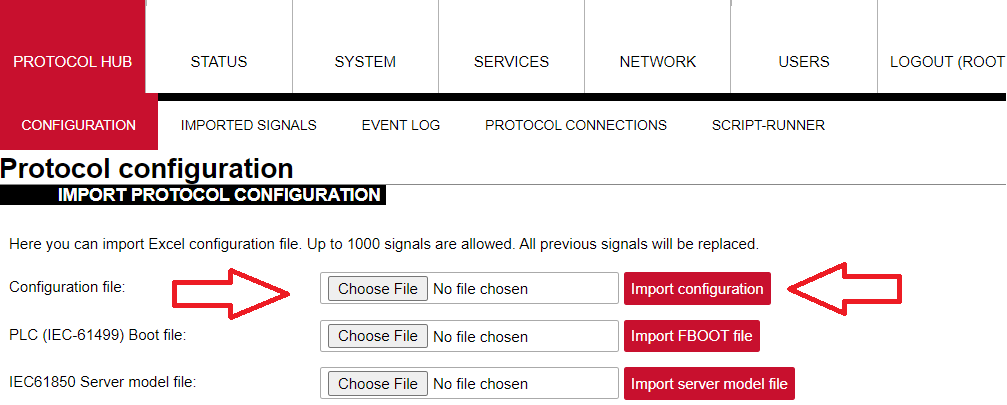

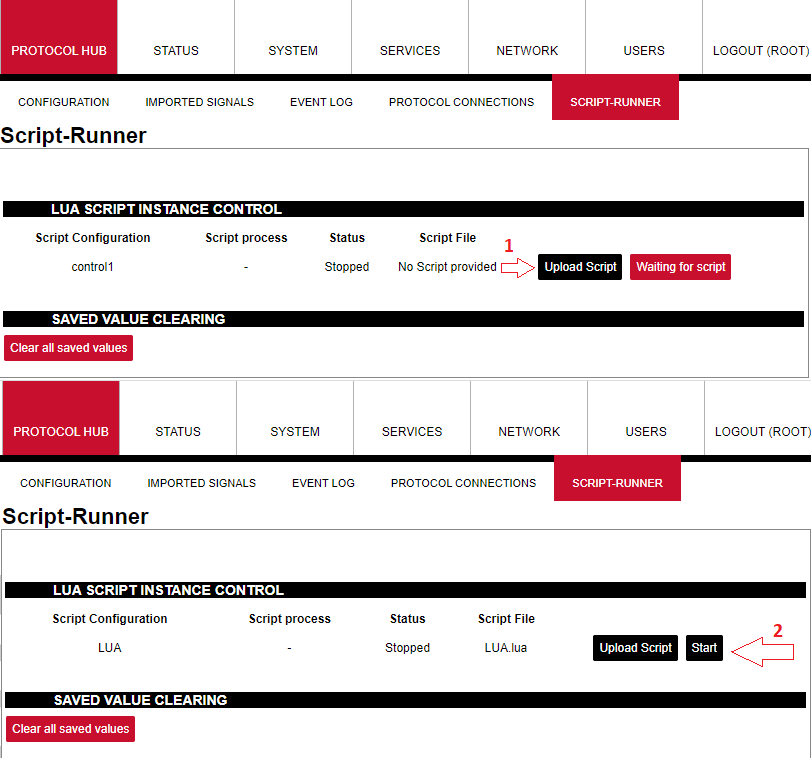

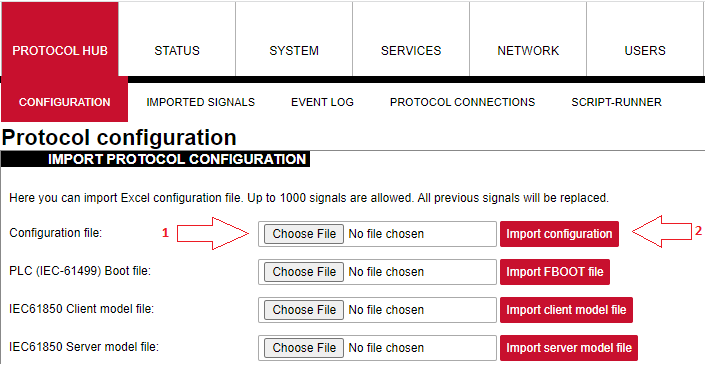

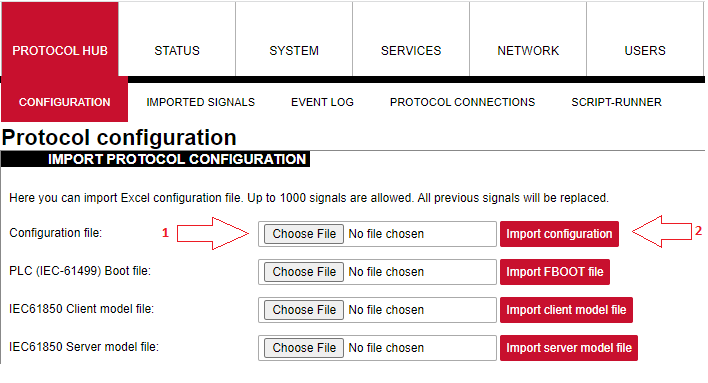

After the configuration is ready, upload it to WCC Lite (Configuration --> Choose file --> Import configuration):

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745396616653.png)

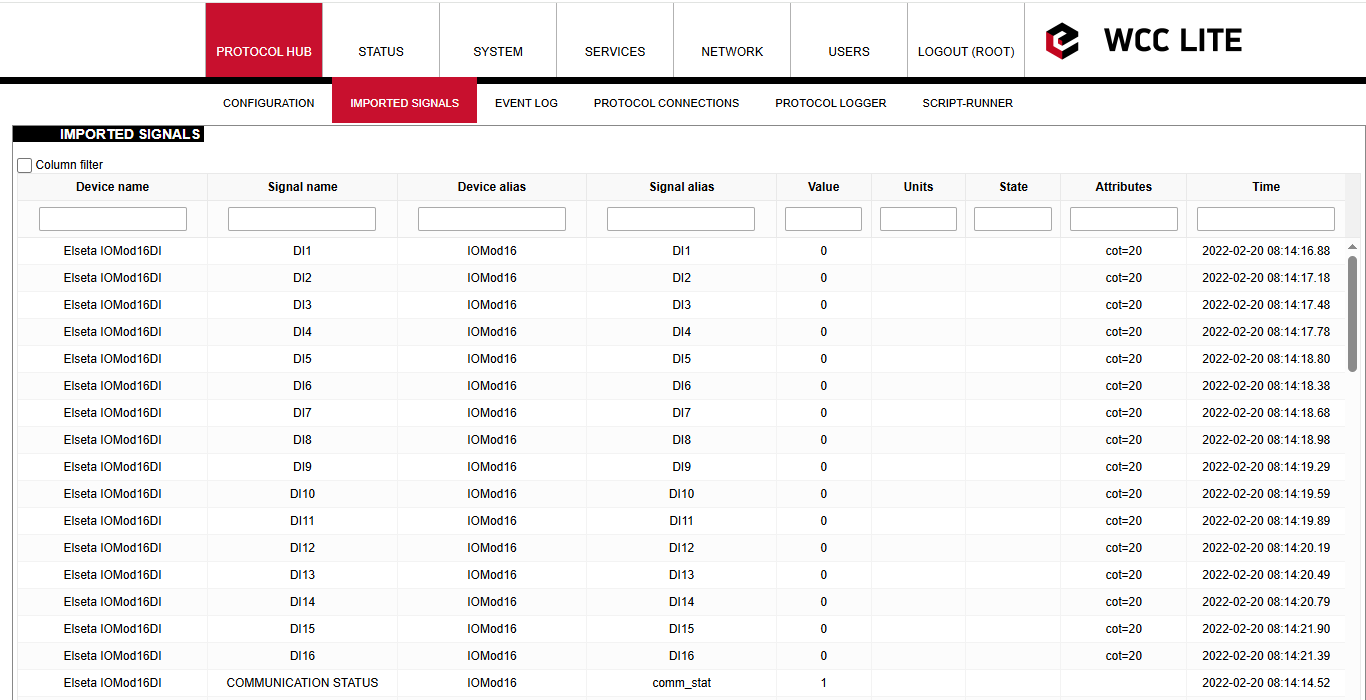

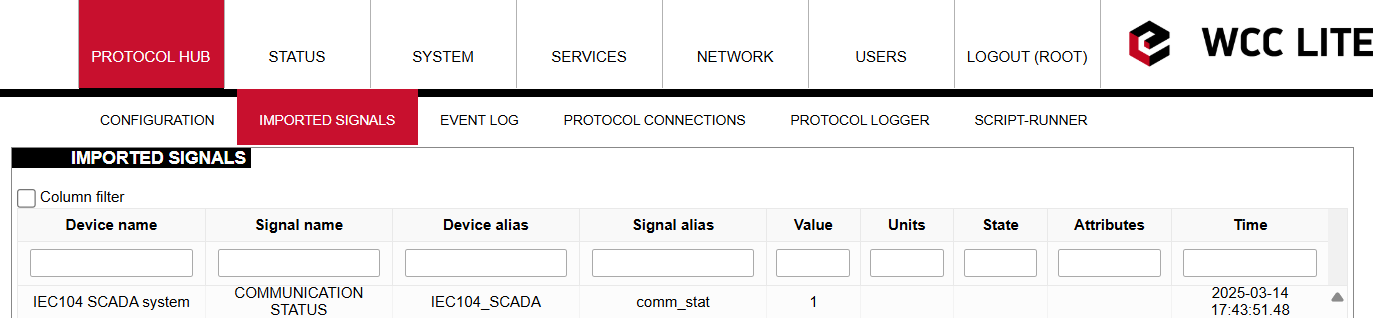

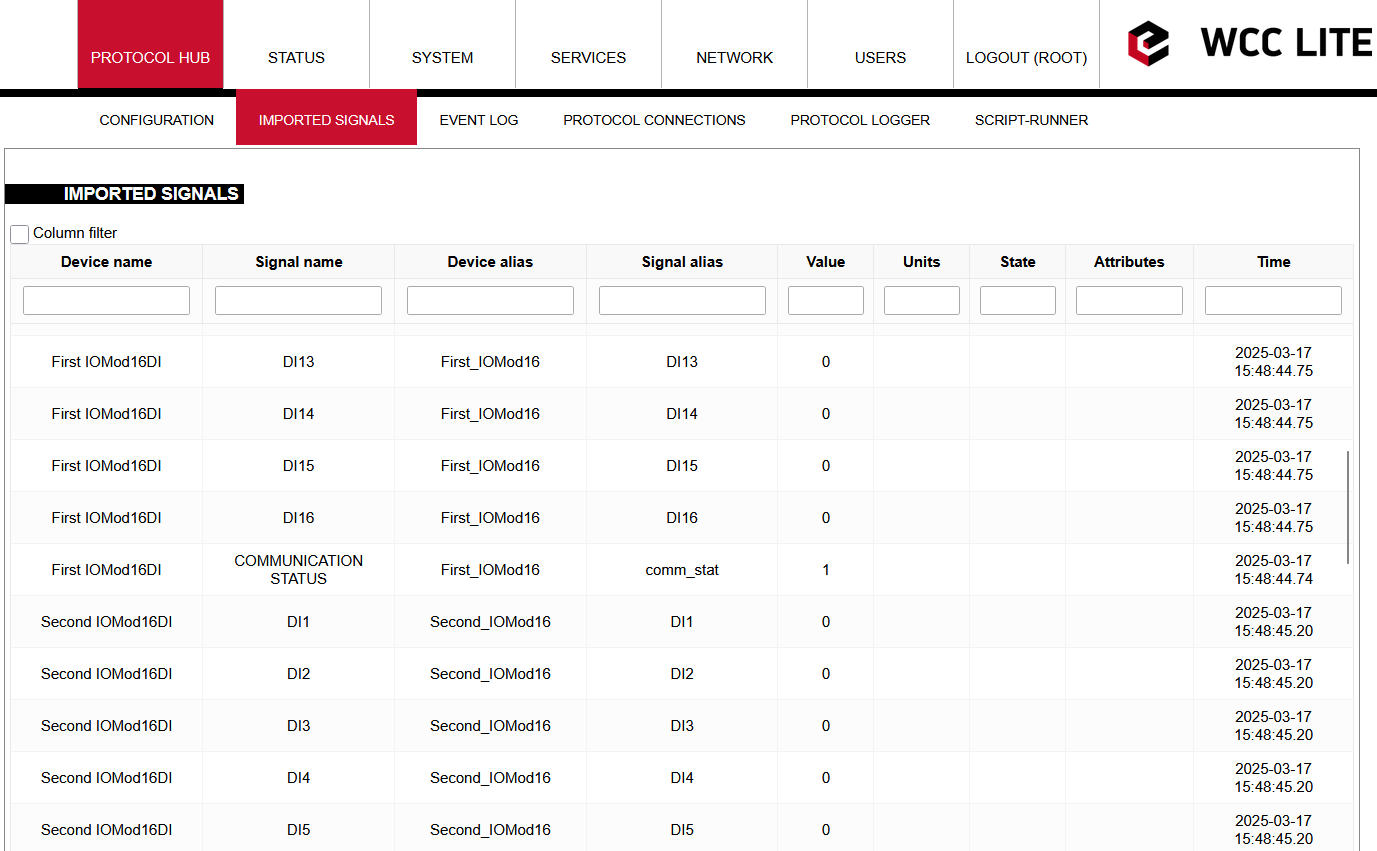

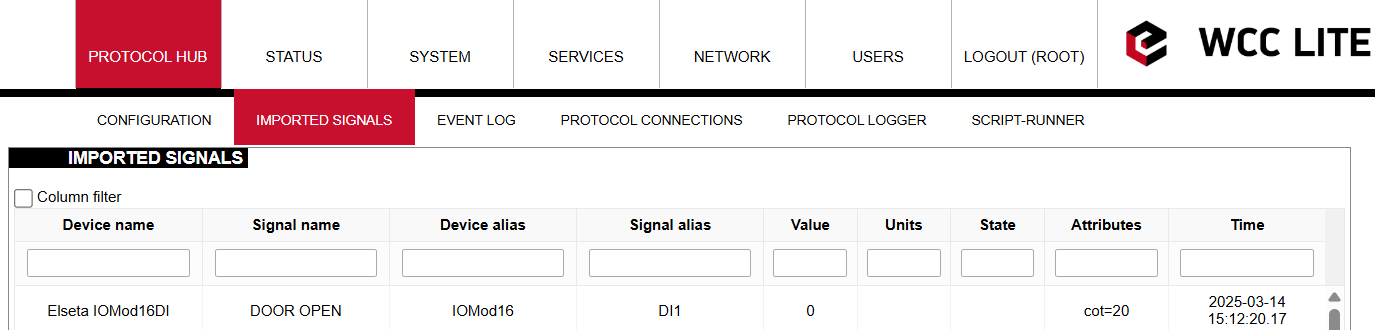

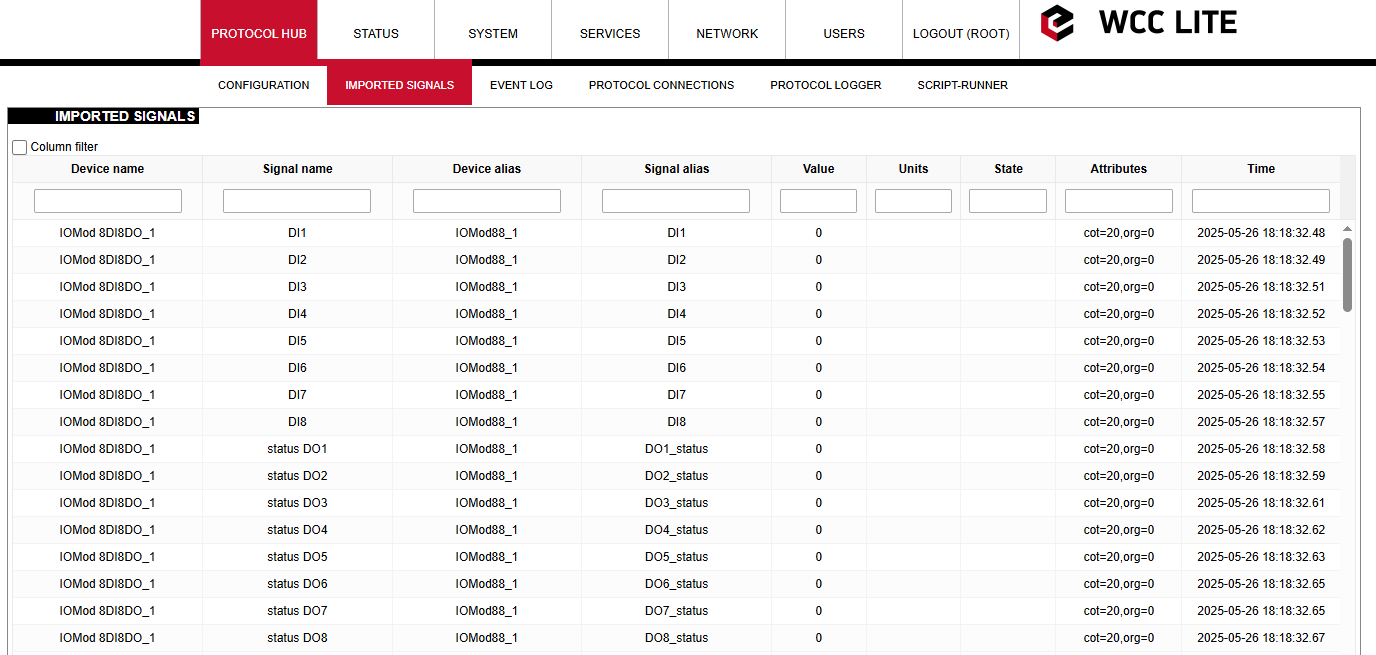

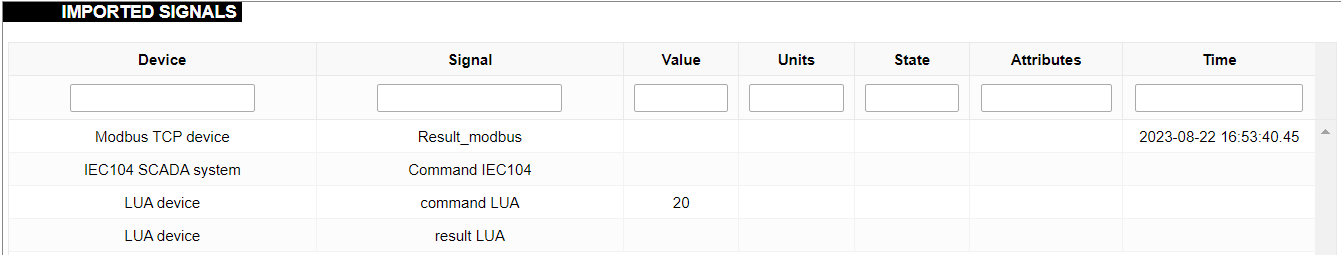

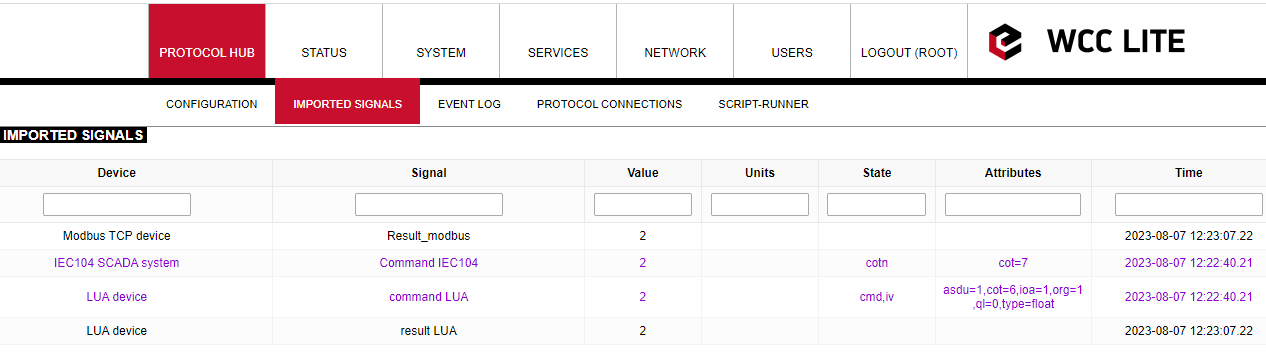

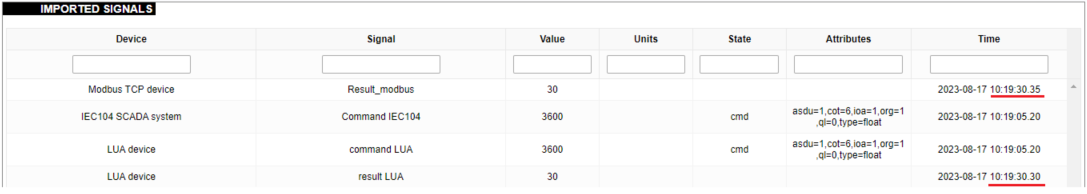

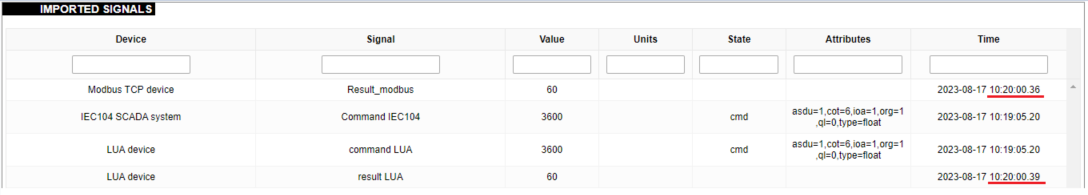

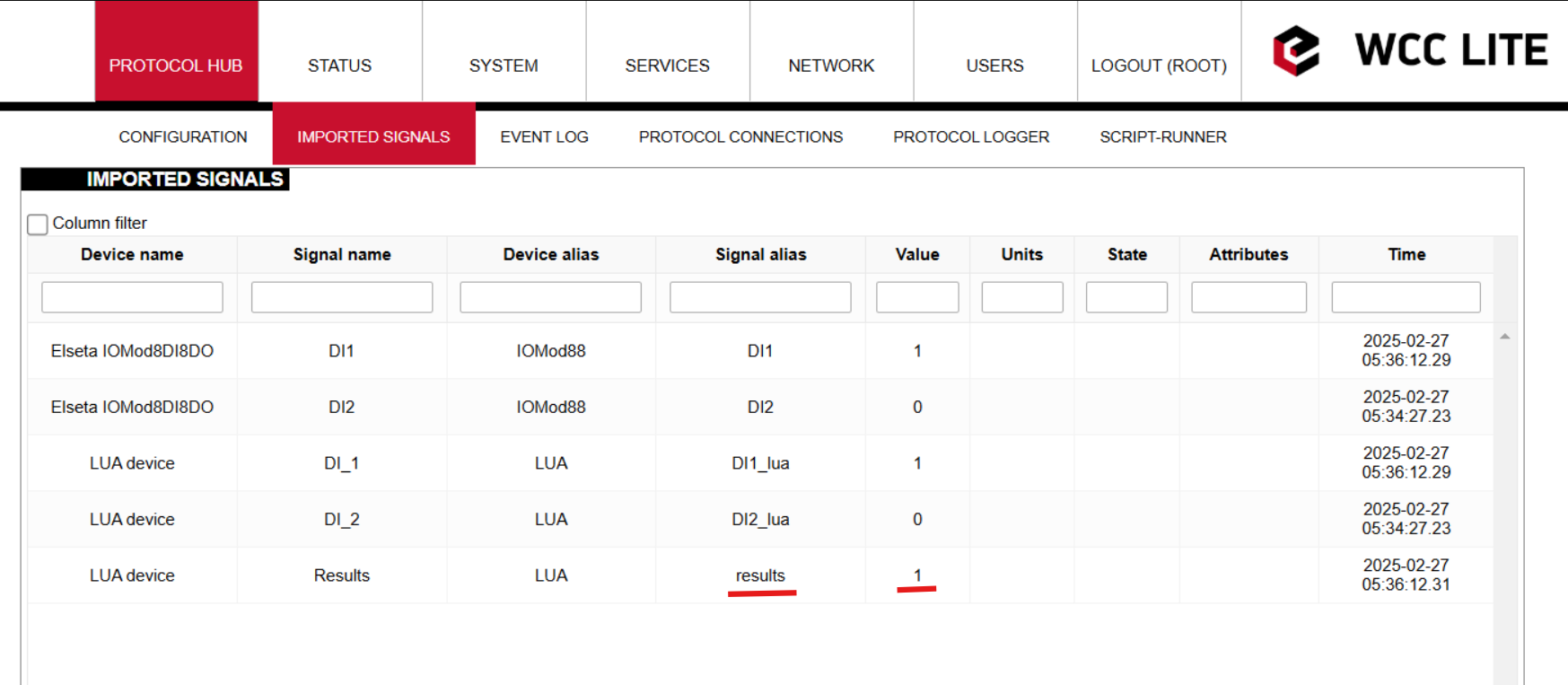

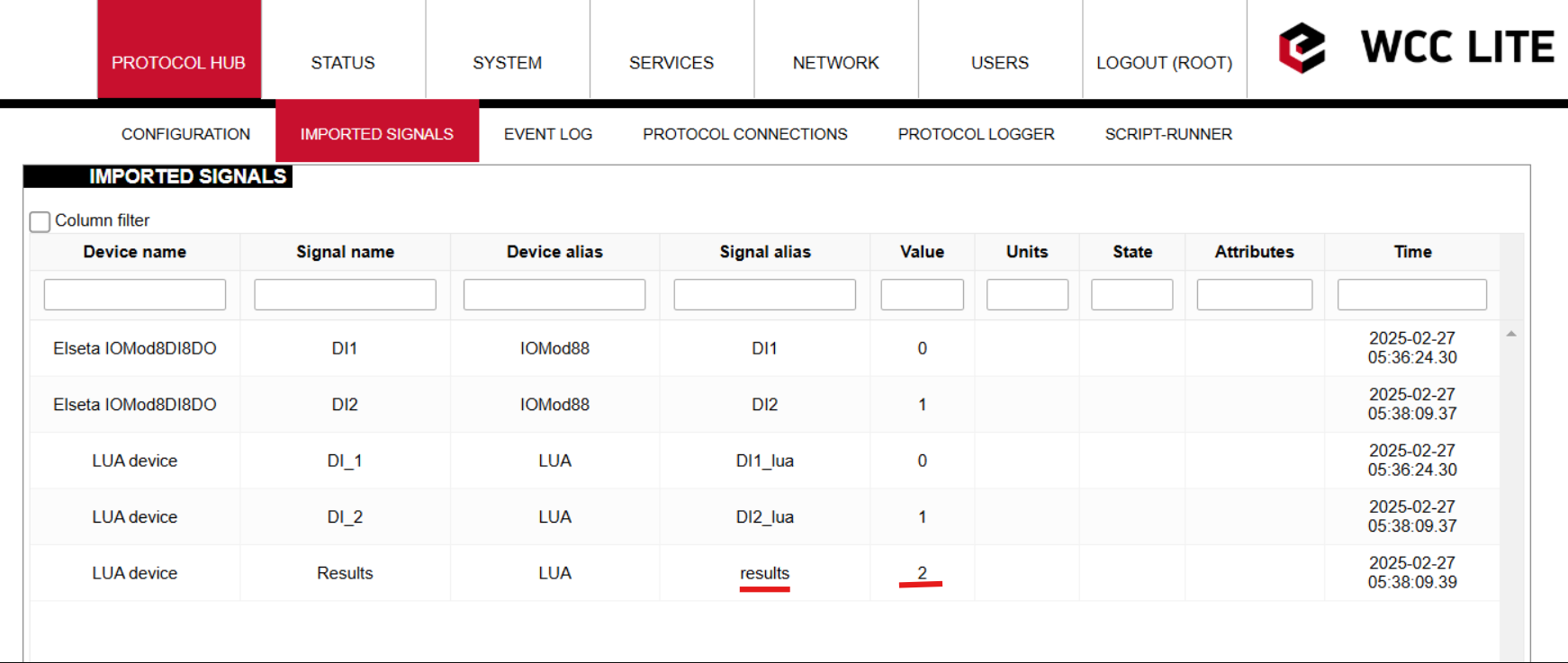

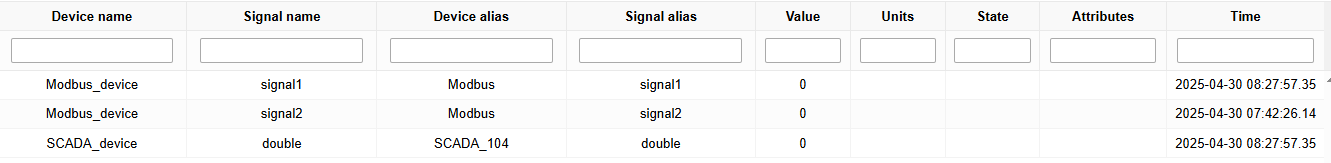

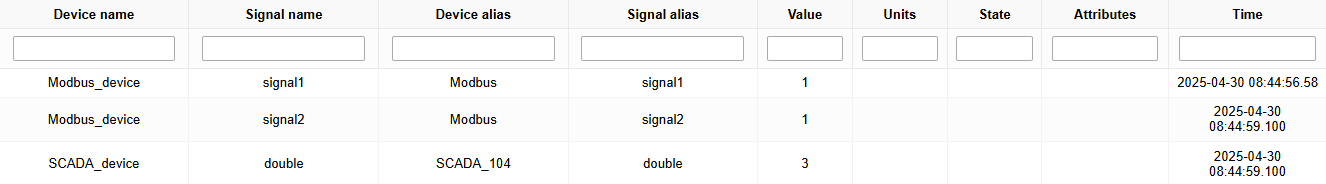

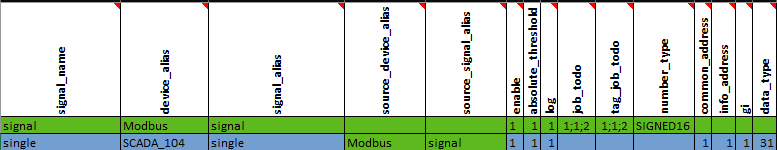

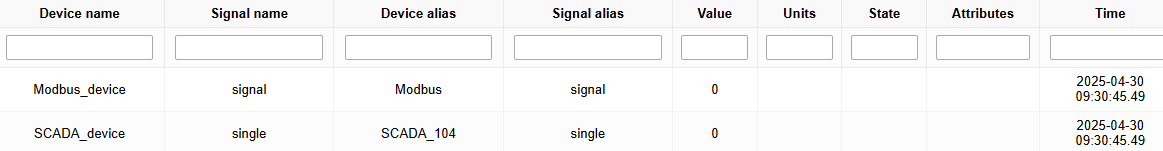

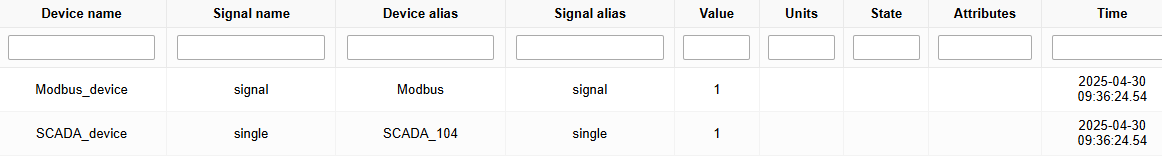

After the upload is done and no errors were detected, you should see all imported signals (Protocol Hub --> Imported signals):

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745398645461.png)

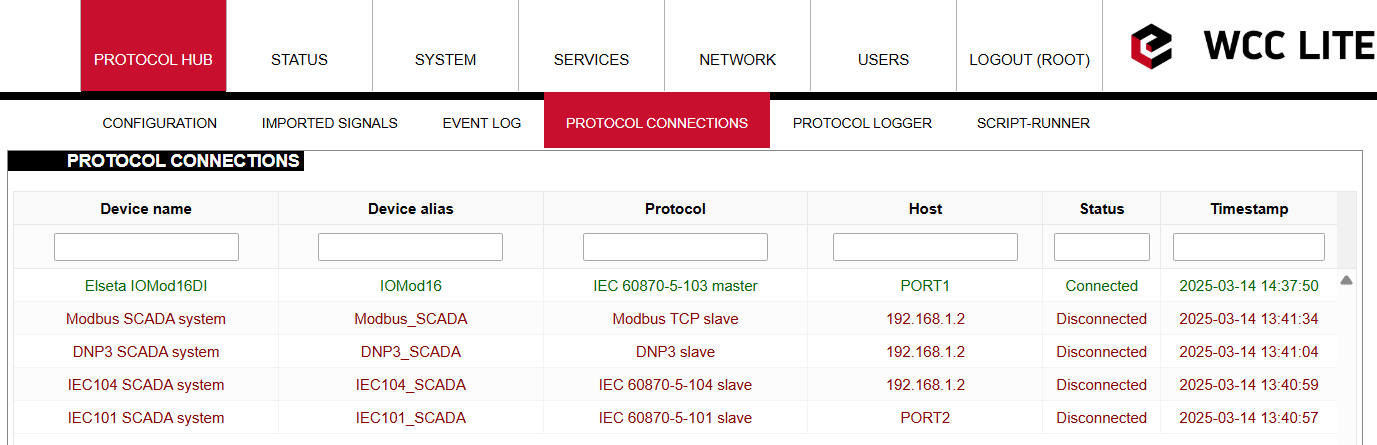

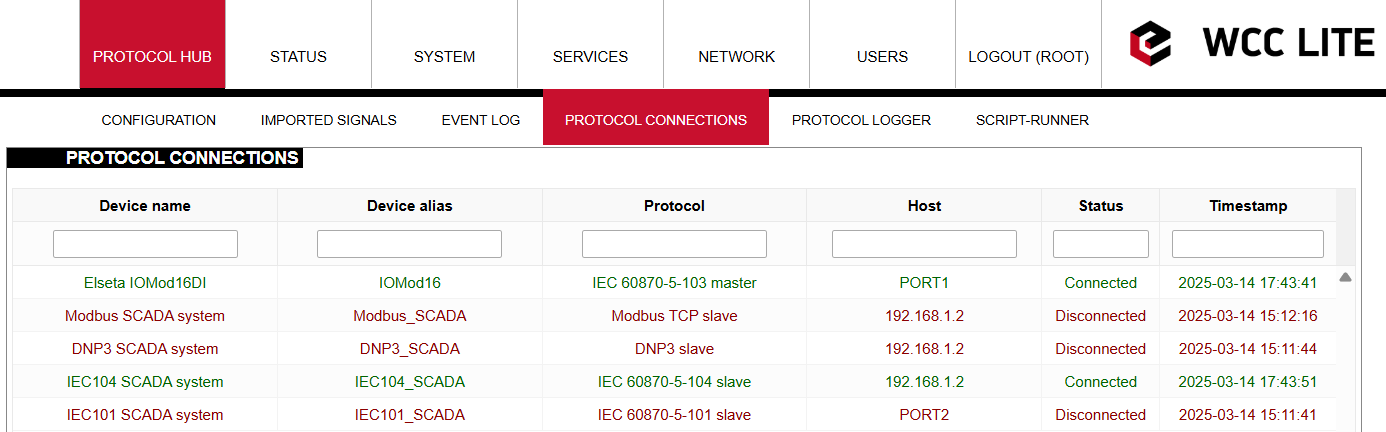

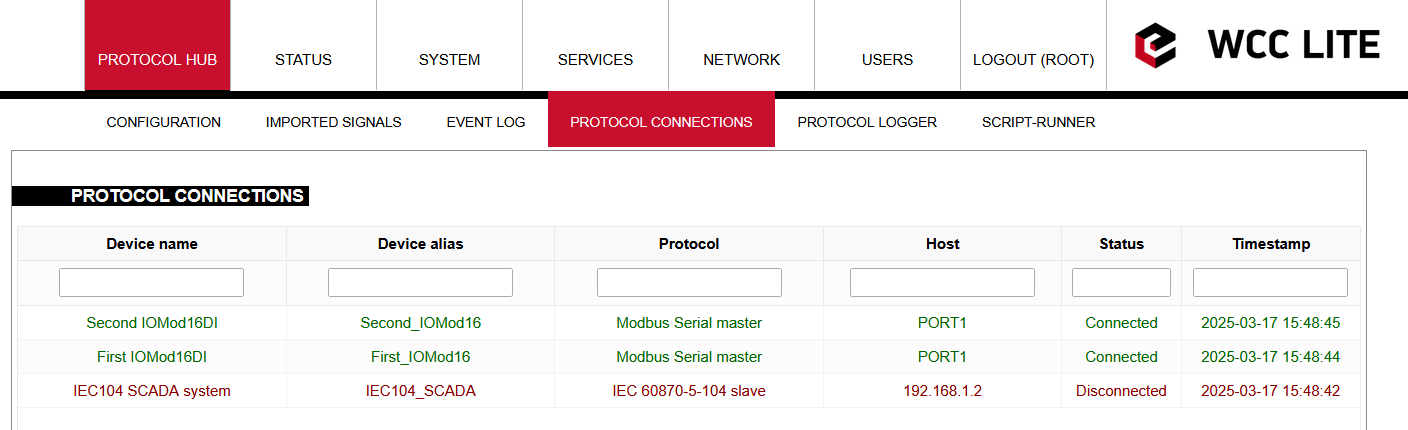

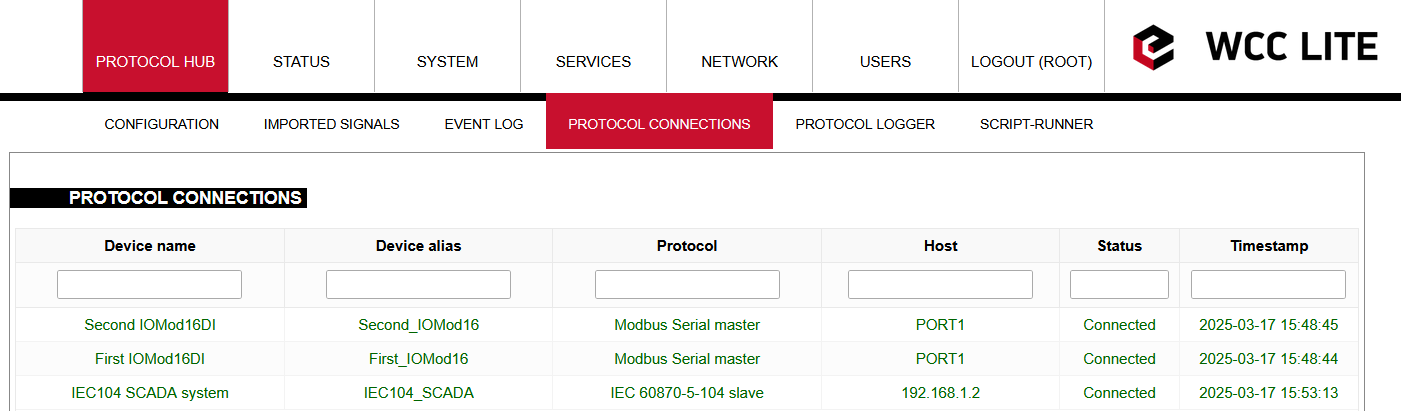

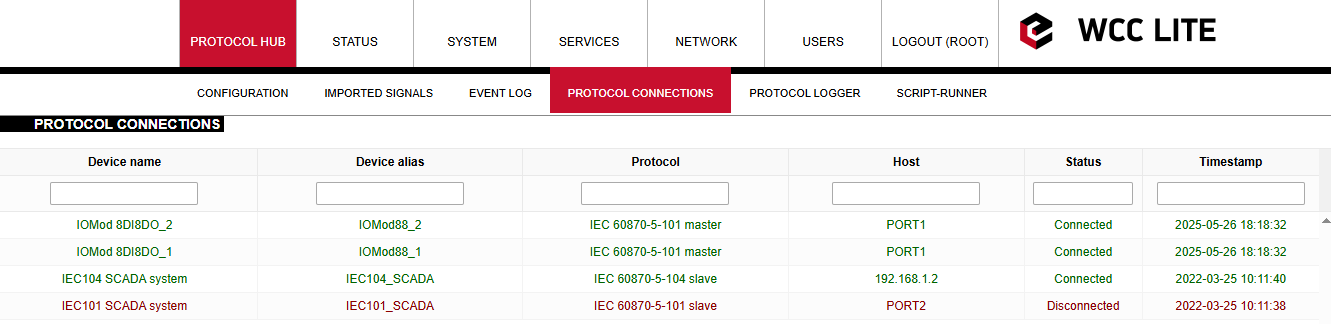

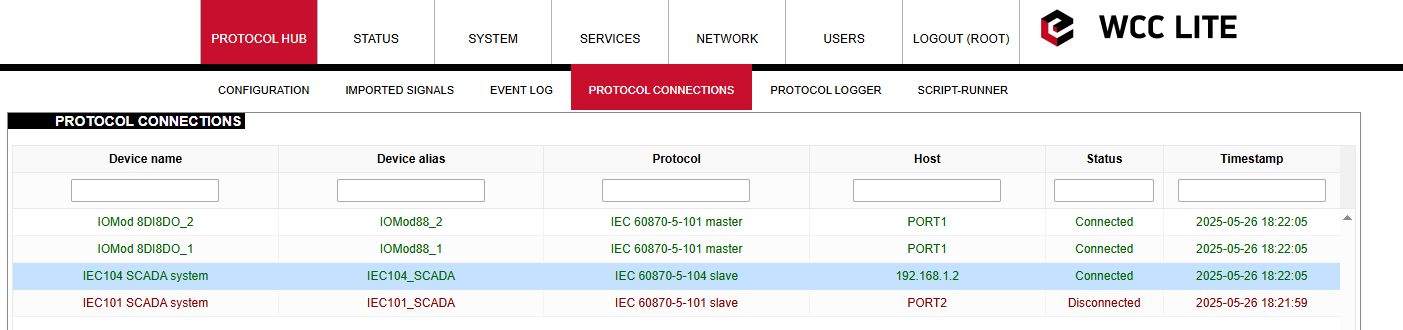

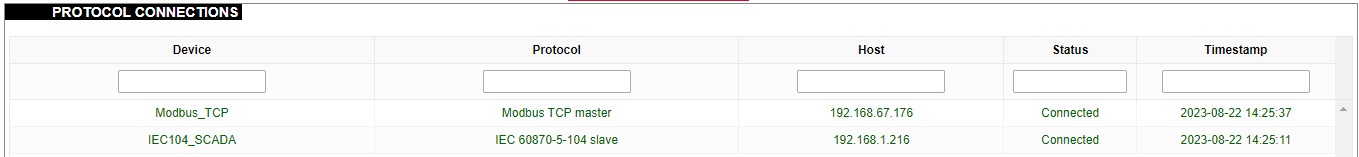

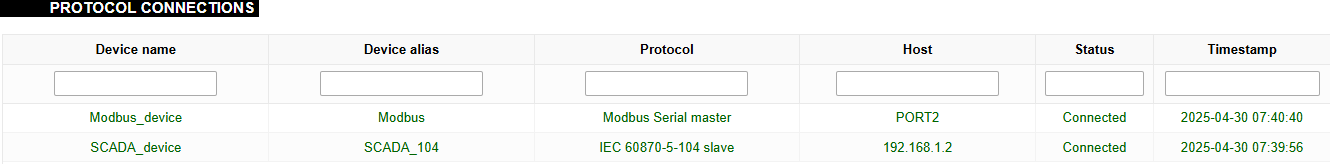

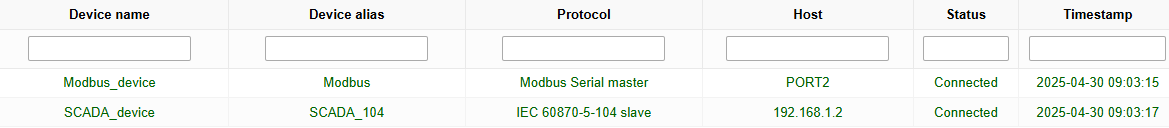

Before doing anything further, you should also check for protocol connections if IOMod 16DI is connected to WCC Lite via PORT1. Go to Protocol connections, where you can see all the connected slave and master protocol devices:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741956075977.png)

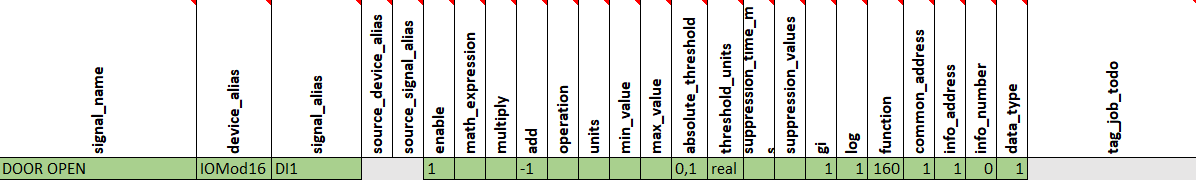

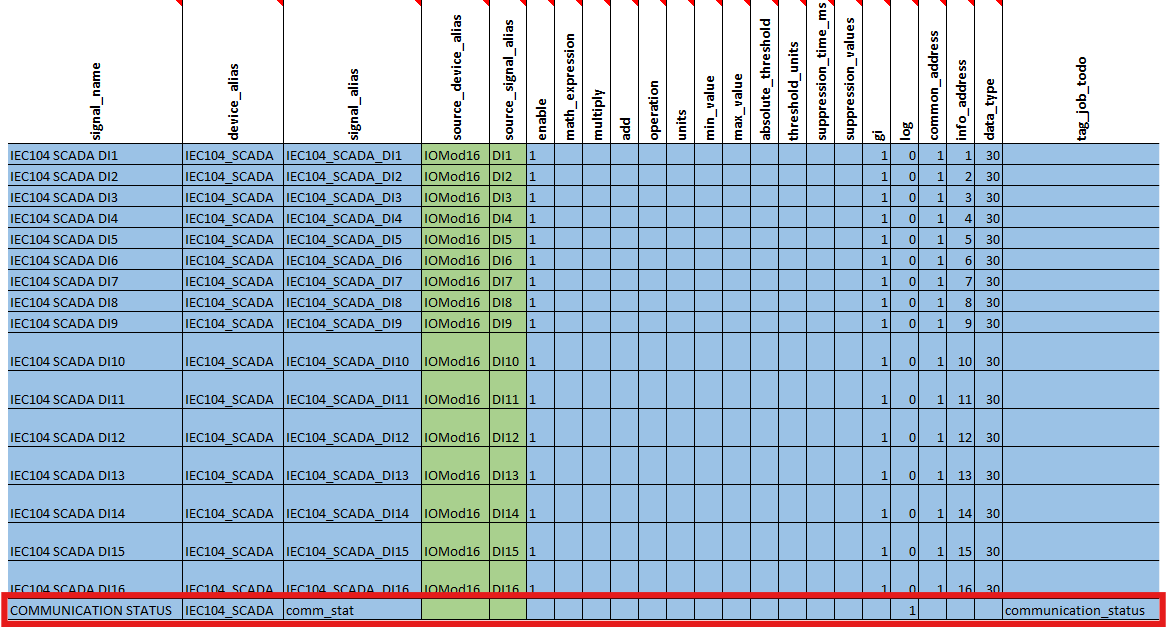

You can also change signal names according to your needs:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741958154237.png)

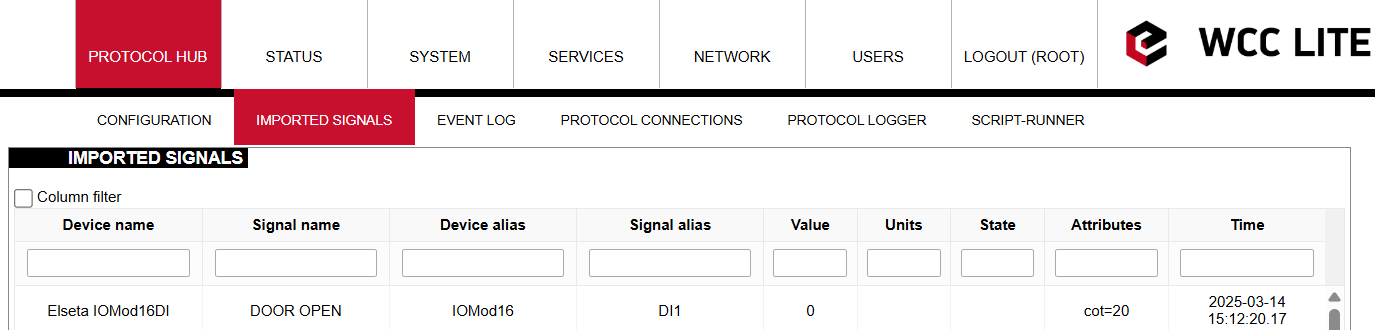

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741958188810.png)

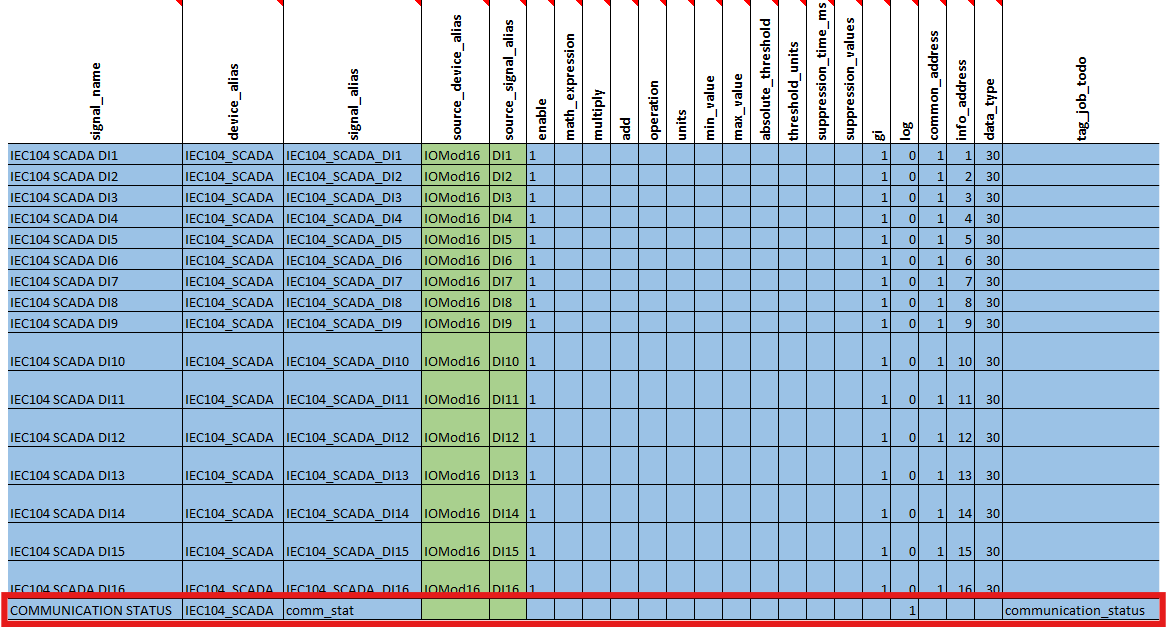

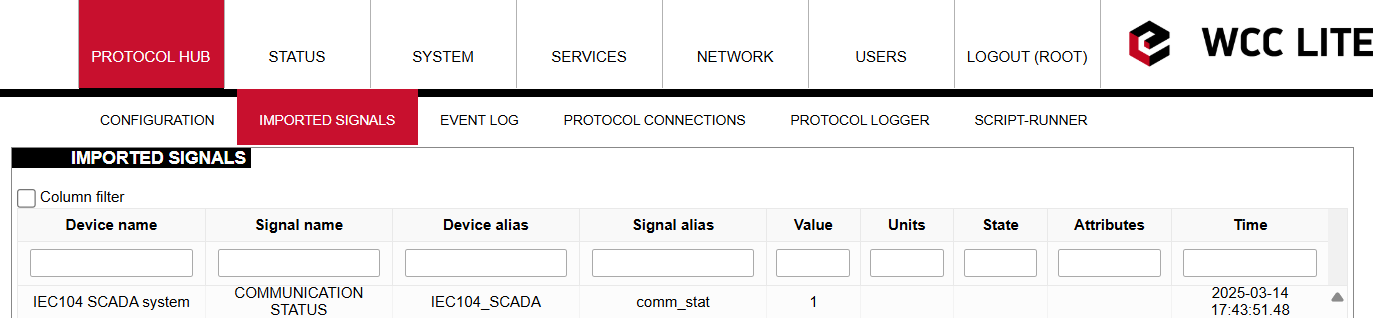

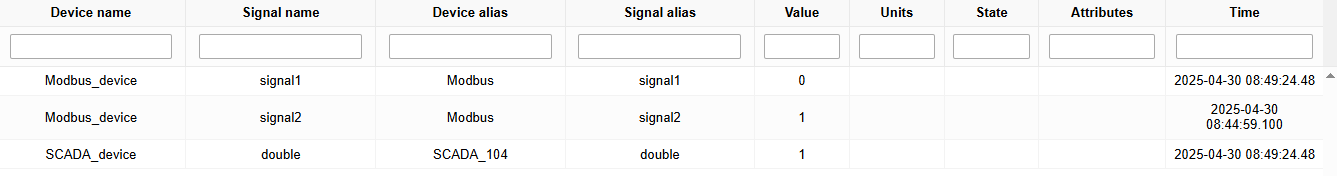

In every signals sheet, you can see a signal named COMMUNICATION STATUS. It is an indicator that shows whether the service is running and whether there is a connection with the device.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741961424044.png)

If everything is connected and service is running, COMMUNICATION STATUS should display 1. Otherwise, if not, it should display 2.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741962018305.png)

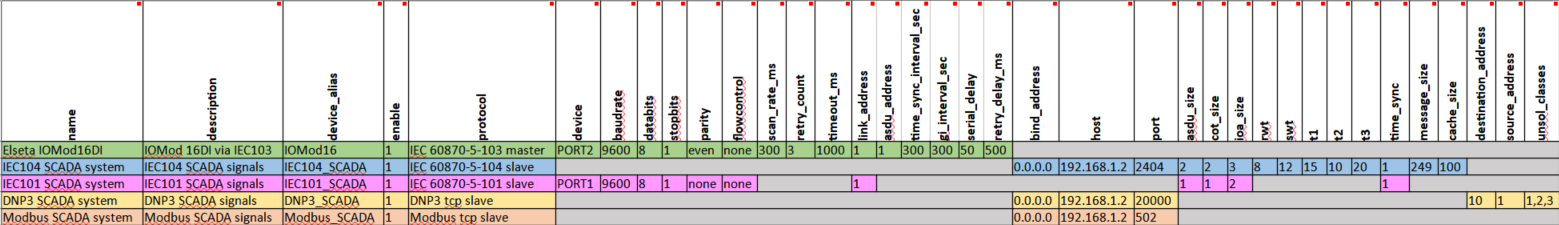

If IOMOD needs to be connected to another port, this could also be changed in the configuration. On the Device sheet, change the Device value from PORT1 to PORT2:

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745412798424.png)

When configuring ports, please note that there can be 2 of the same protocol on the same port (with different IDs, link addresses, etc.), but there cannot be 2 different protocols on the same port.

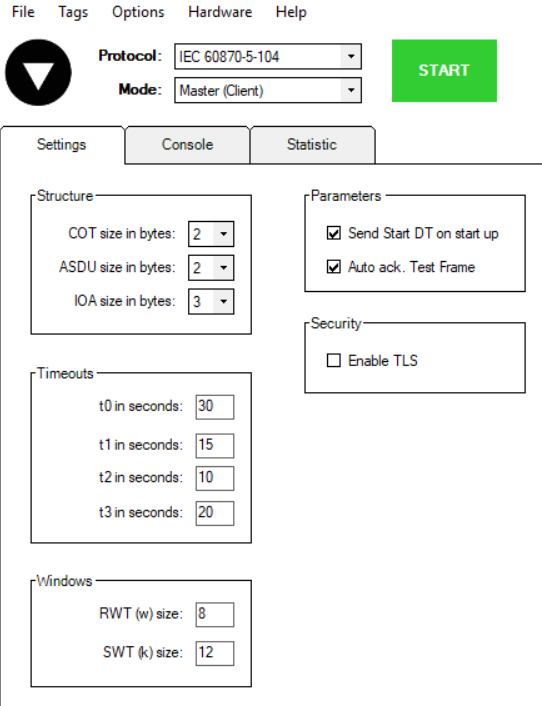

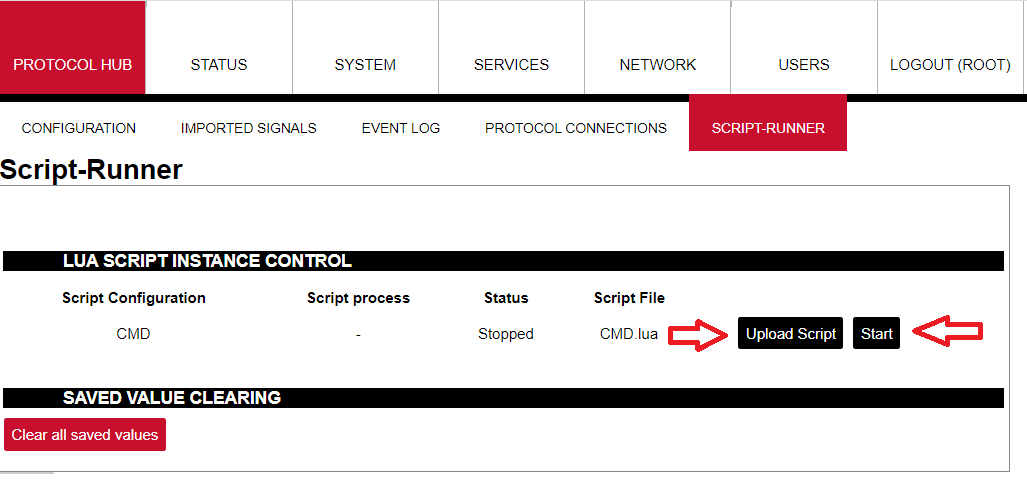

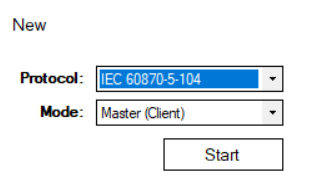

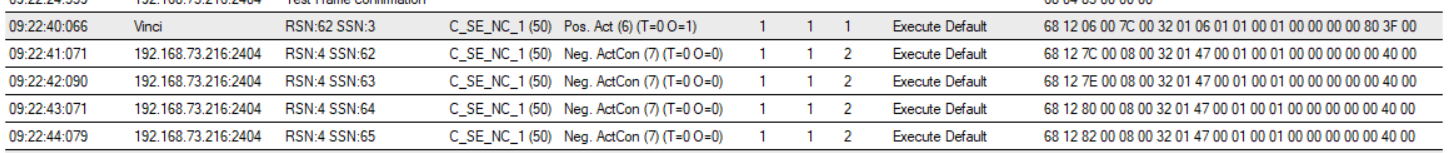

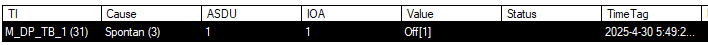

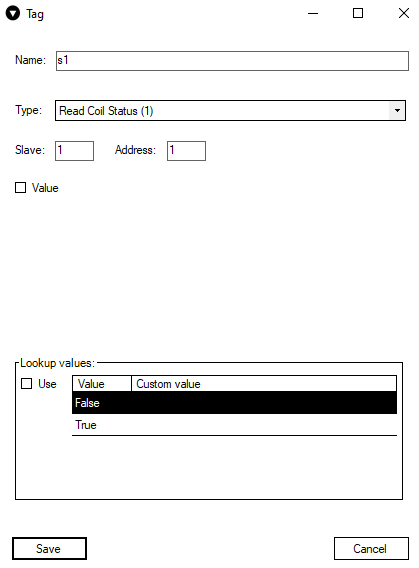

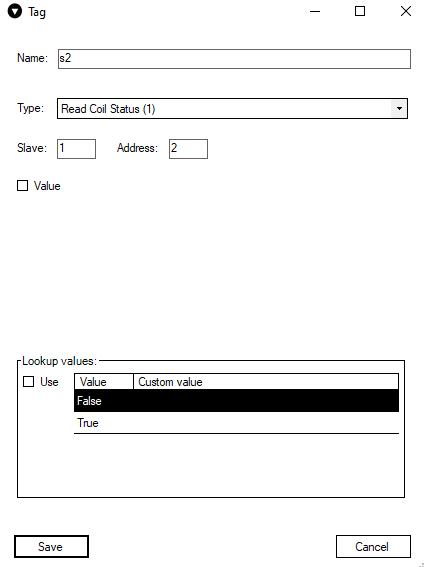

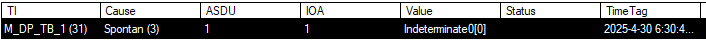

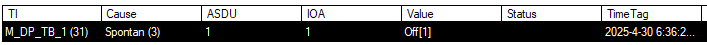

### Simulating SCADA via Vinci software

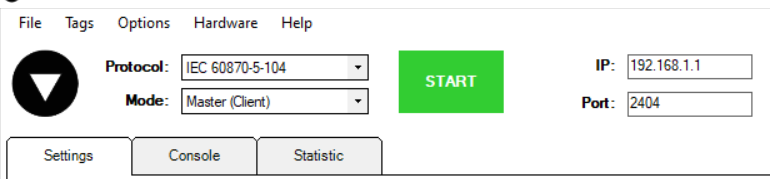

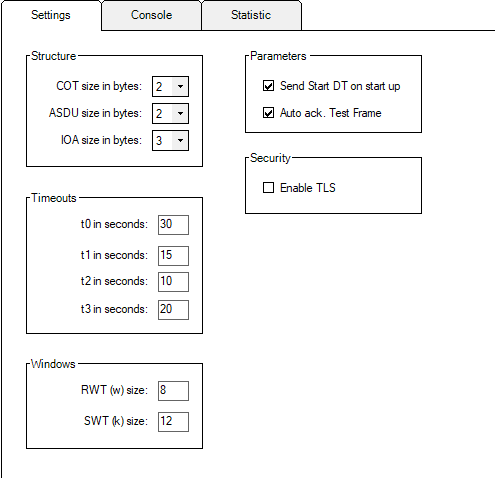

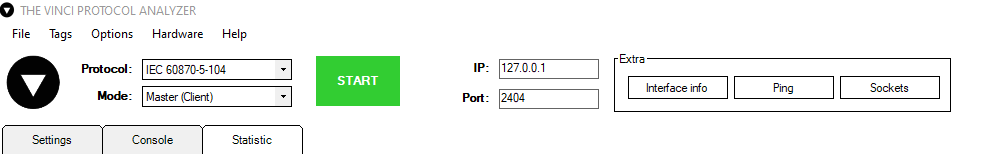

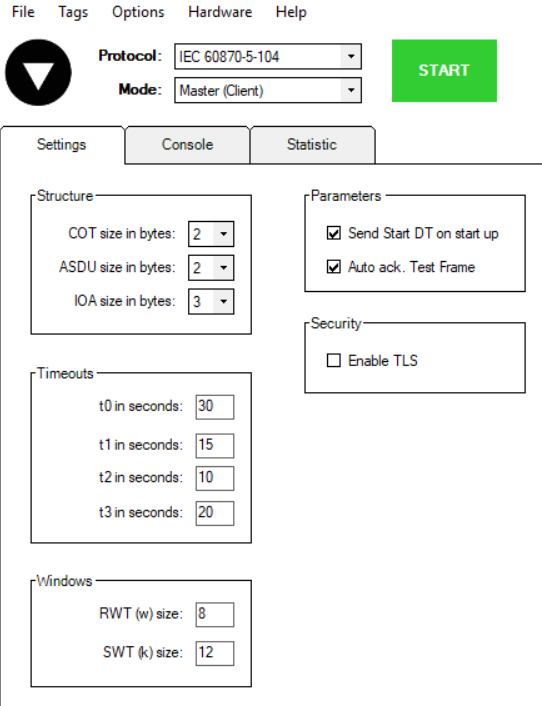

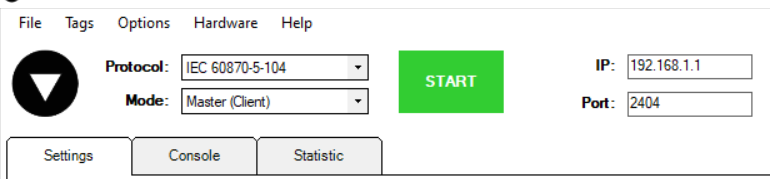

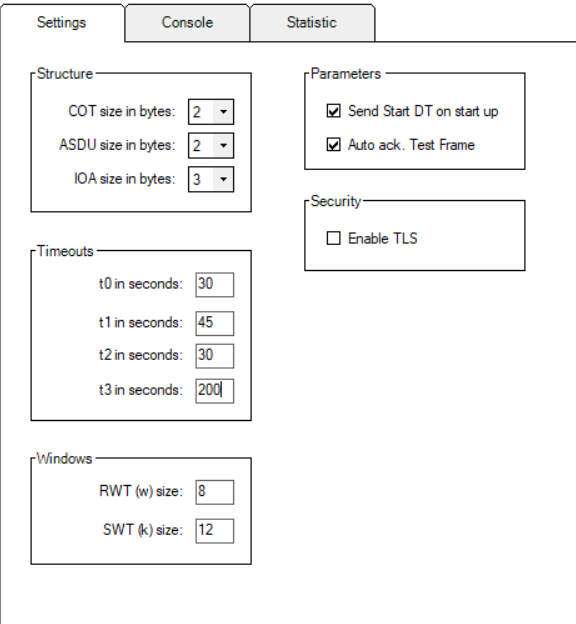

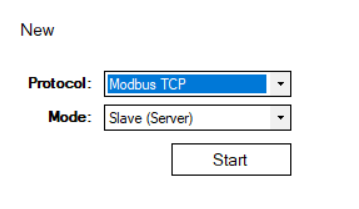

After uploading the Excel configuration, you can simulate SCADA using Vinci software. To simulate an IEC 104 slave, you need to choose the IEC 60870-5-104 protocol and Master(Client) mode and press start. In the *Settings* tab, check Structure, Timeouts and Windows values to match the Excel configuration.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741958787156.png)

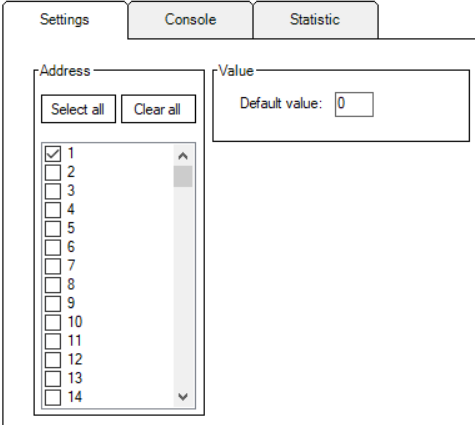

Then set the correct IP address and Port at the top of the program page. **Port** for IEC104 should be 2404, and **IP address** should match your WCC Lite IP address (default address is 192.168.1.1 if it's connected to your computer via an Ethernet cable).

[](https://wiki.elseta.com/uploads/images/gallery/2022-12/image-1671616037090.png)

After clicking start, you should check the protocol connections tab again to see if the IEC104 slave is connected.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741959943539.png)

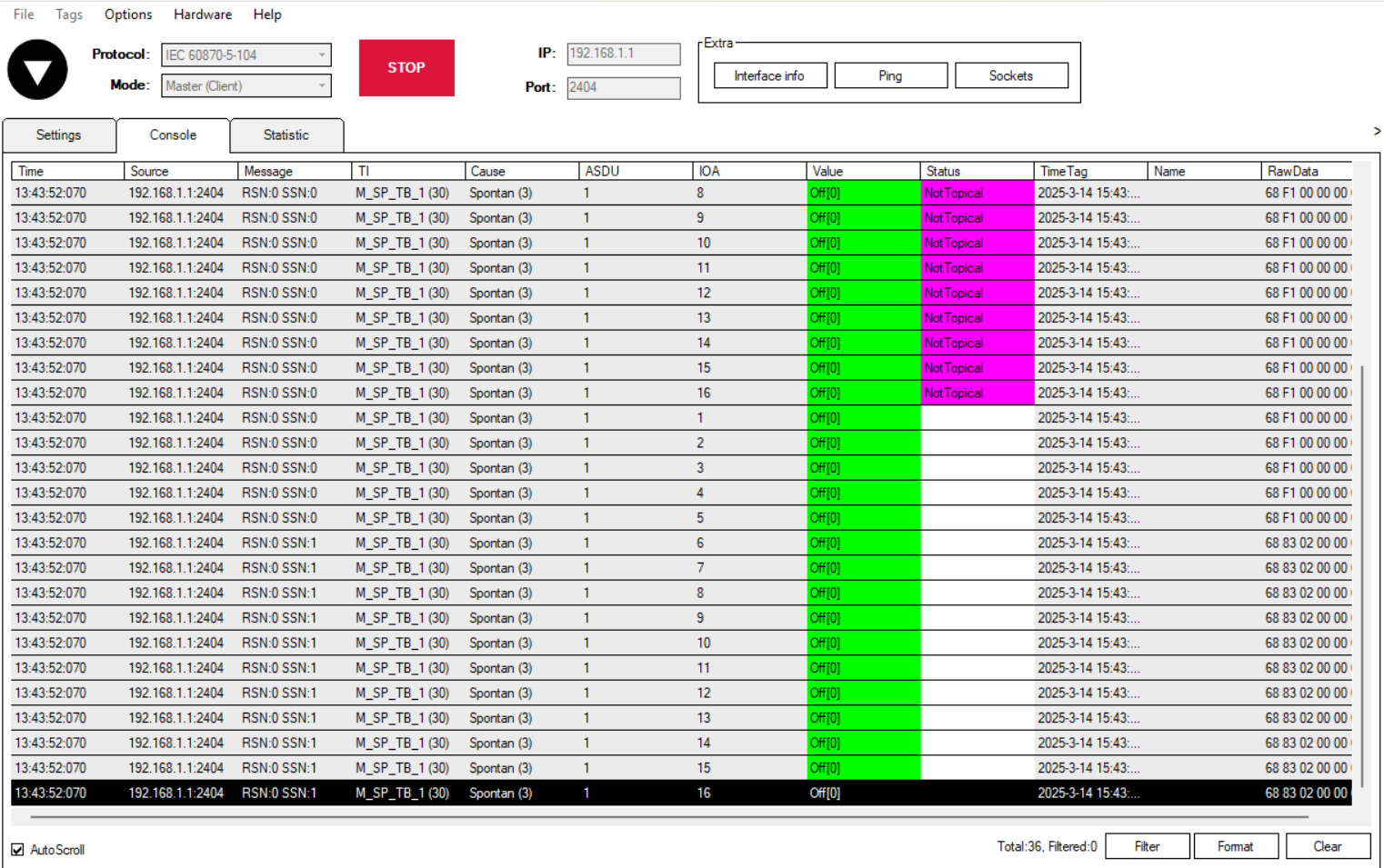

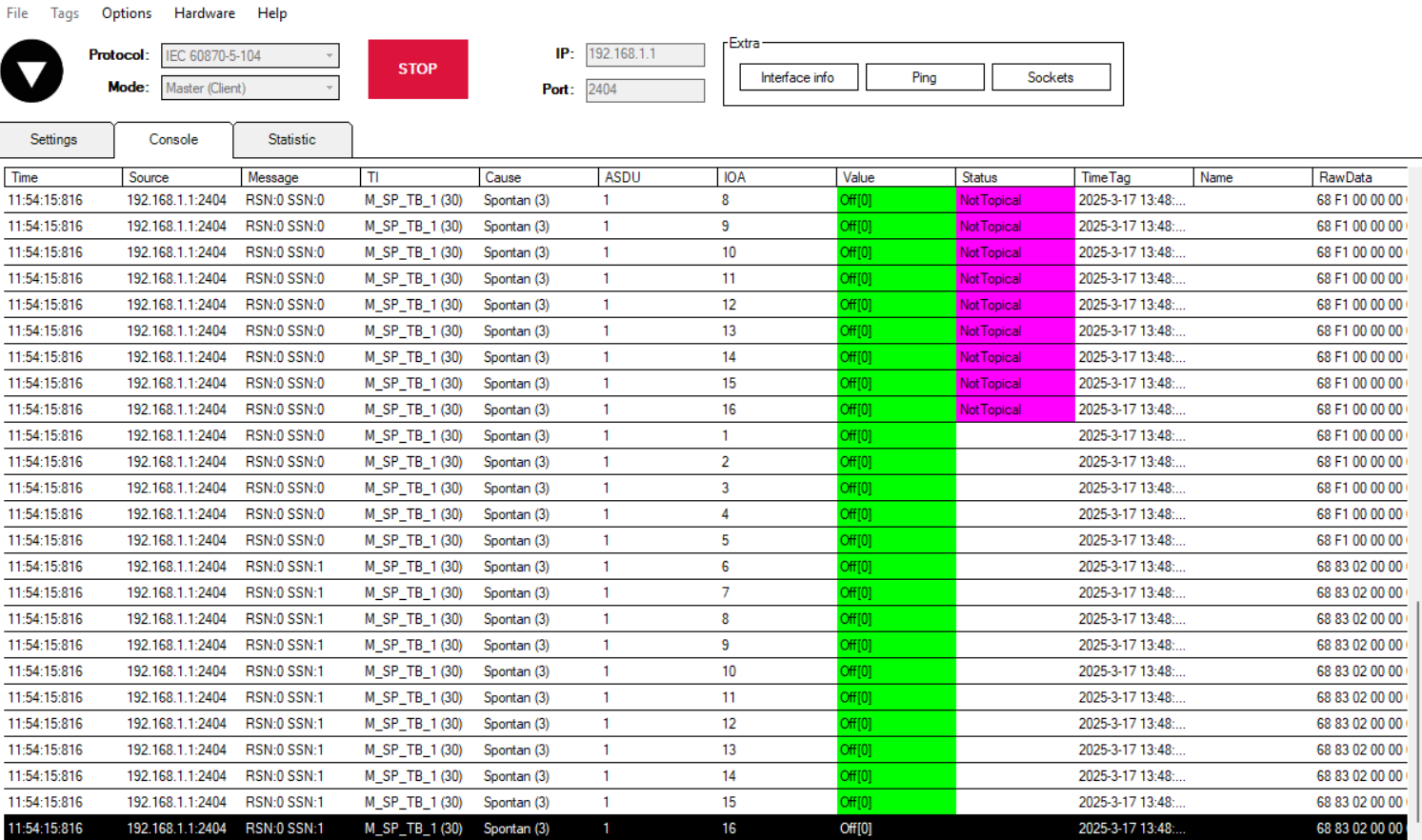

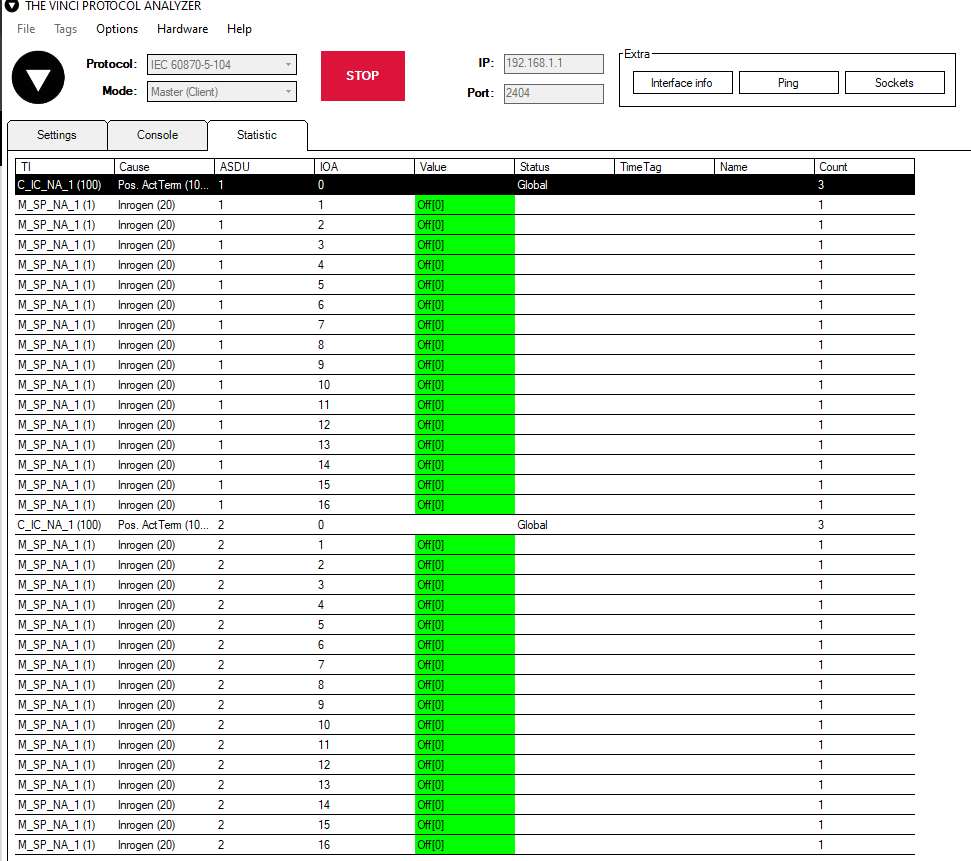

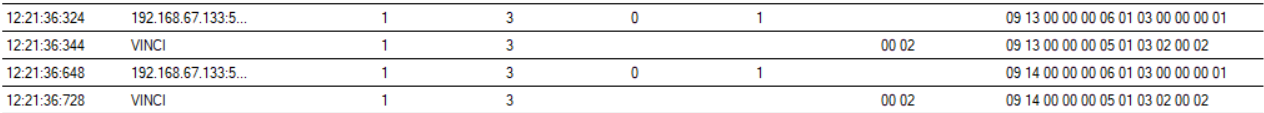

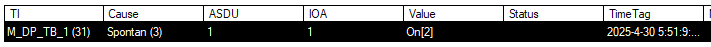

Once the IEC104 slave is connected, the console tab in Vinci software should look something like this:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741959869508.png)

# Connecting two IOMod 16DI

### Description

This article describes how to connect and configure two IOMods 16DI to the WCC Lite using IEC103, and Modbus RTU.

[](https://wiki.elseta.com/uploads/images/gallery/2022-12/image-1670317371132.png)

Typical connection schematic for two IOMod 16DI

WCC Lite can be connected to two IOMod 16DI via PORT1 or PORT2.

### Preparing the configuration

At first, you need to make a configuration for the WCC Lite. This can be done using any spreadsheet editing program. Templates for configuration can be found on the WCC Lite web. Protocol Hub --> Configuration. At the bottom of the page, there will be a *Download* button for template configurations.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1747664622386.png)

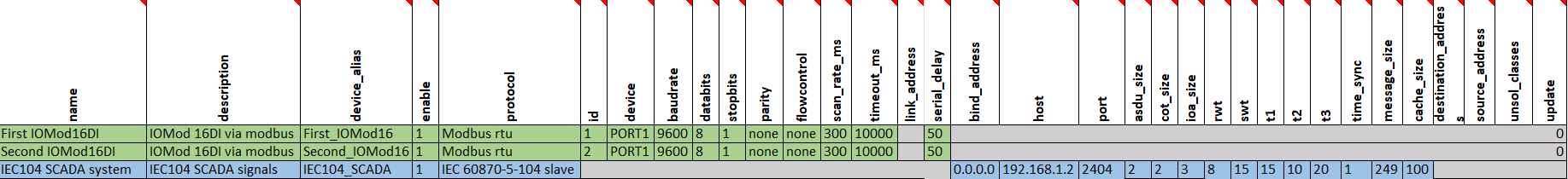

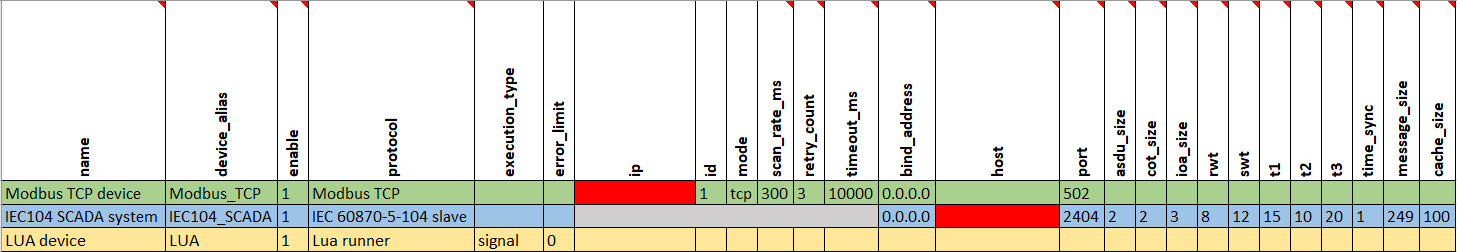

You need to configure the Devices and Signals sheets before continuing. These template configurations can also be used to configure protocols like Modbus-master and DNP3. Configuration can be modified according to the functionality needed. In this case, the *Device* sheet will only have three devices: WCC Lite and two IOMod 16DI. It is important to use only one protocol for each port, otherwise configuration will not work.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1742211726175.png)

You can download the example configuration for each firmware version at the bottom of the article, or create your own using these links:

- For [IEC103](https://wiki.elseta.com/attachments/650)

- For [IEC101](https://wiki.elseta.com/attachments/649)

- For [Modbus](https://wiki.elseta.com/attachments/648)

You need to configure the devices and signal sheets before continuing. After downloading template configurations, open the phub templates folder. You will see that there are different template folders for each IOMod:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741952060514.png)

To select a correct configuration, check the sticker on the back of the IOMod. There, you will find which protocol to use according to Factory FW type. For example, if you have IOMod 16DI with IEC103 FW, select configuration iomod\_16DI\_IEC103\_to\_IEC104\_DNP3\_Modbus\_SCADA.

IOMOD needs to be configured, as in the Excel configuration. If templates are being used, default parameters should be set for the IOMOD. IOMODs with firmware version 1 are configured via PuTTY or other SSH programs using the USB port on the device's front panel. This can be done following the [IOMod 16DI user manual](https://wiki.elseta.com/attachments/647).

IOMOD also has a series of parameters that can be configured directly for the IOMOD without changing the WCC Lite configuration. Each IOMOD has its unique parameters, which can be seen on the configuration menu.

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745916922979.png)

A new menu opens by clicking \[6\], allowing the user to configure the 16DI inputs. Input grouping allows grouping of neighbour inputs, the first being an odd-numbered input. This then makes the grouped inputs a double-point input. When making an Excel configuration for WCC Lite with double-point information, the even-numbered input signal should be deleted, and the odd-numbered input signal should be configured as a double-point signal.

The user can also change the input filter time. This parameter is set in milliseconds and determines the time after which the input is represented with the changed state. For example, if the filter time is 1000ms, and the input has been on for 500ms, the state won't change from OFF to ON. This is relevant when seeking to avoid unnecessary data.

### Uploading configuration

Template configurations can work with default settings without any further changes. These template configurations can also be used to configure protocols like Modbus-master and DNP3. Configuration can be modified according to the functionality needed. For that, you can rely on the examples given in the links above (Preparing the configuration). If you need to specify different IEC104 slave settings, you can do that by changing the Excel configuration. By changing settings such as *info\_address* or *data\_type,* you can adapt the IEC104 slave to work as needed. To test this example, specify your computer's IP address in the Excel configuration for the IEC104 slave.

After the configuration is ready, upload it to WCC Lite (Configuration --> Choose file --> Import configuration):

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1747727323347.png)

After the upload is done and no errors were detected, you should see all imported signals (Protocol Hub --> Imported signals):

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1742212283072.png)

Before doing anything further, you should also check for protocol connections if both IOMod 16DI are connected to WCC Lite via PORT1. Go to Protocol connections, where you can see all the connected slave and master protocol devices:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1742212346712.png)

You can also change signal names according to your needs:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741958154237.png)

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741958188810.png)

In every signals sheet, you can see a signal named COMMUNICATION STATUS. It is an indicator that shows whether the service is running and whether there is a connection with the device.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741961424044.png)

If everything is connected and service is running, COMMUNICATION STATUS should display 1. Otherwise, if not, it should display 2.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741962018305.png)

If IOMOD needs to be connected to another port, this could also be changed in the configuration. On the Device sheet, change the Device value from PORT1 to PORT2:

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745412798424.png)

When configuring ports, please note that there can be 2 of the same protocol on the same port (with different IDs, link addresses, etc.), but there cannot be 2 different protocols on the same port.

### Connecting IEC104-slave via Vinci

After Excel and USB configurations, you can connect to the device using the Vinci software. To simulate an IEC 104 slave, you need to choose the IEC 60870-5-104 protocol and Master(Client) mode and press start. In the *Settings* tab, check Structure, Timeouts and Windows values to match Excel configuration.

[](https://wiki.elseta.com/uploads/images/gallery/2022-12/image-1670320501413.png)

Then set the correct IP address and Port at the top of the program page. **Port** for IEC104 should be 2404, and **IP address** should match your WCC Lite IP address.

[](https://wiki.elseta.com/uploads/images/gallery/2022-12/image-1670320526682.png)

After clicking start, you should check the protocol connections tab again to see if the IEC104 slave is connected.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1742212491674.png)

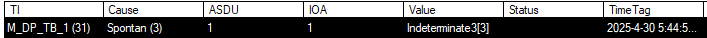

Once the IEC104 slave is connected, the console tab in Vinci software should look something like this:

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1742212470033.png)

If you want to configure IOMod 16DI, you should refer to -> [IOMod 16DI User Manual](https://wiki.elseta.com/attachments/646).

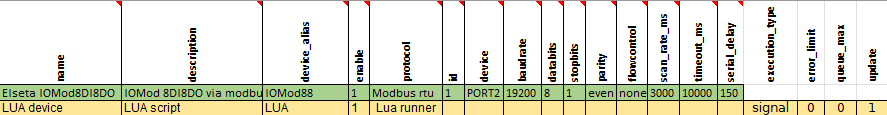

# Connecting 2x 8DI8DO IOMod to the WCC Lite

### Description

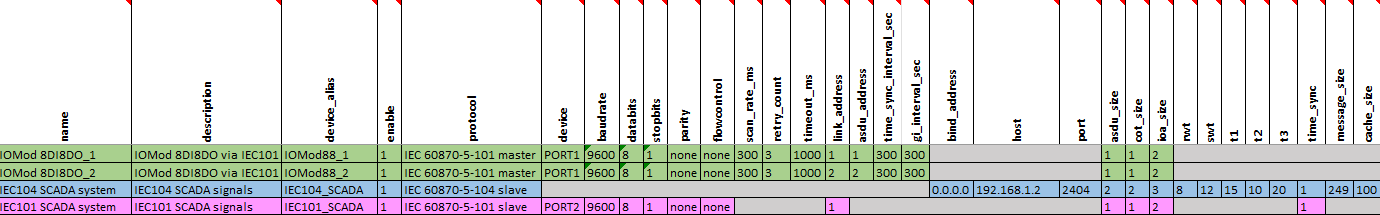

This article describes connecting and configuring two IOMOD 8DI8DO to the WCC Lite PORT1.

Each IOMod must be configured to match the Excel configuration. If using the template configuration, default parameters should be applied to the IOMod. IOMODs with firmware version 2 are configured using the [IOMod utility application](https://wiki.elseta.com/books/tools-and-software/page/iomod-utility) either via the USB port on the device's front panel or via the RS-485. Refer to the [IOMod 8DI8DO user manual](https://wiki.elseta.com/books/iomod-8di8do/page/iomod-8di8do-user-manual)

Each IOMOD has its own set of parameters that can be adjusted without modifying the WCC Lite configuration. These can be accessed through the device's configuration menu.

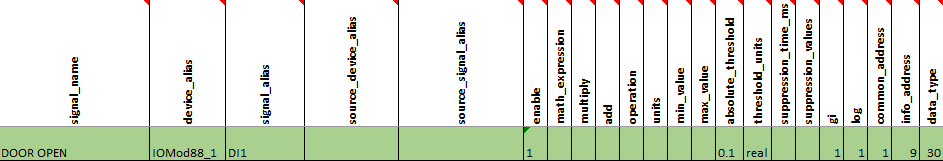

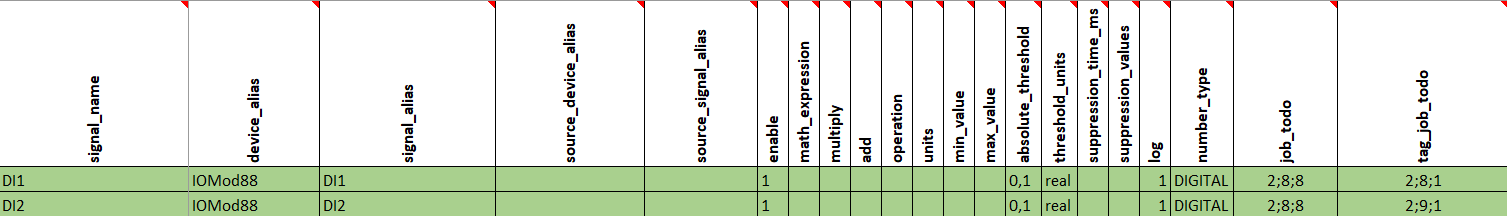

If you are creating a custom configuration, especially when multiple devices of the same type are connected to the same port, make sure that the *Device\_alias* values are unique for each device in the Devices sheet. Link address values must be different. Additionally, in the Signals sheet, Device\_alias and Signal\_alias combinations must not be duplicated across different devices.

### Uploading configuration

The configuration can be modified to suit your specific needs. You can use the example provided above ([2x\_8DI8DO.xlsx](https://wiki.elseta.com/attachments/679)) as a reference. If different IEC104 slave settings are required, they can be modified in the Excel configuration. For example, you can adjust settings such as info\_address or data\_type to match the desired behavior of the IEC104 slave. To test this example, specify your computer's IP address in the IEC104 slave’s host column in the Excel file.

Once the configuration is ready, upload it to WCC Lite via Configuration --> Choose file --> Import configuration.

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1745396616653.png)

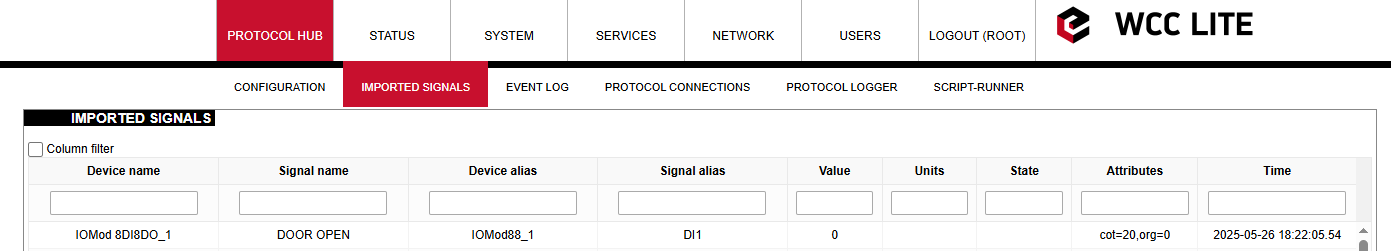

After the upload completes and no errors are detected, go to Protocol Hub --> Imported signals to verify that all signals have been successfully imported.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748261969330.png)

Before proceeding, check the protocol connections to confirm that both IOMOD 8DI8DO devices are connected to WCC Lite via PORT1. Open the Protocol Connections section to view all connected slave and master protocol devices.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748261988953.png)

You can rename signal names according to your preferences.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748262063541.png)

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748263782202.png)

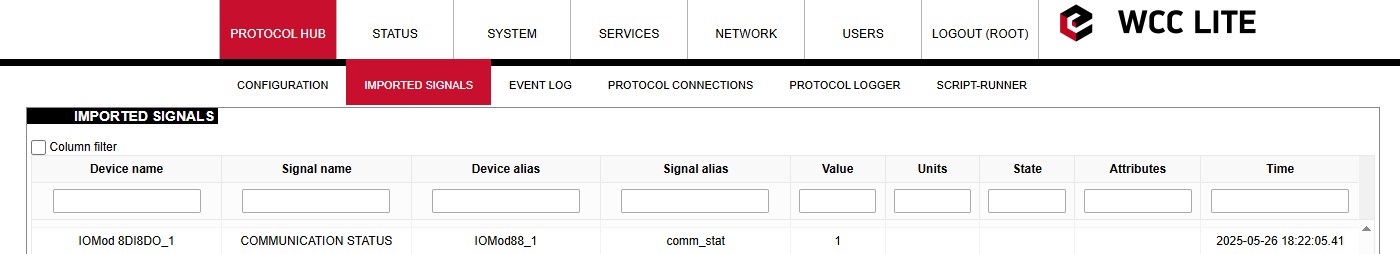

In every signals sheet, there is a signal named COMMUNICATION STATUS. This signal indicates whether the WCC Lite has established a connection with the device.

If everything is connected correctly and the service is running, the COMMUNICATION STATUS should display a value of 1. If not connected, it will display a value of 2.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748264210950.png)

If the IOMOD needs to be connected to another port, you can change the configuration by updating the Device value in the Devices sheet from PORT1 to PORT2.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748267088069.png)

Please note that each port on the WCC Lite can only run a single protocol. Mixing different protocols on the same port is not supported. In addition, each device must have unique values for parameters such as ID, link address, and ASDU address.

### Simulating SCADA via Vinci software

After uploading the Excel configuration, you can simulate a SCADA connection using Vinci software. To simulate an IEC 104 slave, select the IEC 60870-5-104 protocol, choose Master (Client) mode, and press Start. In the Settings tab, make sure the Structure (COT, ASDU, and IOA size), Timeouts, and Windows values match those defined in the Excel configuration.

[](https://wiki.elseta.com/uploads/images/gallery/2025-03/image-1741958787156.png)

Set the correct IP address and port at the top of the Vinci window. The default IEC104 port is 2404. The IP address should match the IP of your WCC Lite device (by default, 192.168.1.1 if connected directly to your computer via Ethernet).

[](https://wiki.elseta.com/uploads/images/gallery/2022-12/image-1671616037090.png)

After clicking Start, open the Protocol Connections tab again to verify that the IEC104 slave is connected.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748264814531.png)

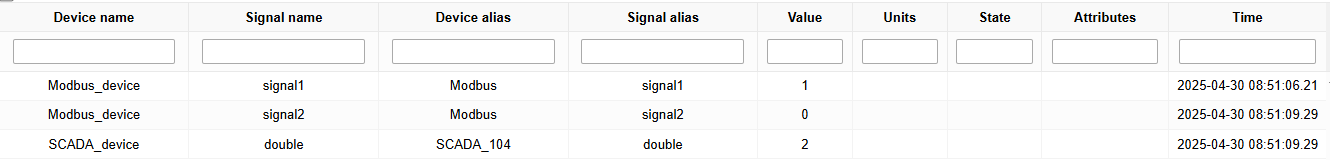

Once the IEC104 slave is connected, send a General Interrogation (GI) command. If everything is working correctly, the Statistics tab in Vinci should begin to display live data.

[](https://wiki.elseta.com/uploads/images/gallery/2025-05/image-1748264942085.png)

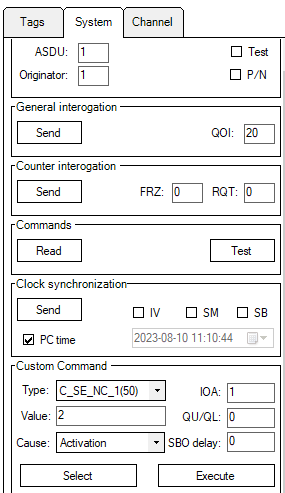

To test further, let's activate the first digital output (DO1) on both IOMODs. To do this, we will send a type 45 command (C\_SC\_NA\_1).

In the Excel configuration, under the sheet *Signals\_IEC104*, we specified that to activate the output on the first IOMOD, the command must be sent with the following parameters:

ASDU (common\_address) = 1, IOA (info\_address) = 101, type (data\_type) = 45.

For testing the second IOMOD, we assigned DO1 to IOA = 1001. The procedure remains the same—send a command with type = 45, this time using ASDU = 2, IOA = 1001.

# Protocol conversions

# Comlynx to Modbus TCP protocol conversion

## Description

This article describes WCC Lite configuration steps to enable Comlynx protocol conversion to Modbus TCP

[](https://wiki.elseta.com/uploads/images/gallery/2020-10/image-1601994154261.png)

## First steps

Before you begin, make sure you have completed all physical installation work according to the manufacturer's installation instructions.

Set up your computer and connect Ethernet cable to WCC Lite ETH0 port. Login with default credentials and setup basic required settings (name, network, users, etc. ). You can find configuration tutorials in [How to](https://wiki.elseta.com/books/how-to) articles.

After setup, download configuration template from device (Protocol Hub → Configuration → Template configuration Download)

Or download configuration example from this article [Files](#h_52402507611602751244400).

To prepare configuration fill information in both - [Devices](#bkmrk-configure-devices) and [Signals](#bkmrk-configure-signals) sheets:

## Configure devices

Add connected inverter with ComLynx protocol required information:

**name**

**device\_alias**

**enable**

**protocol**

**timeout\_ms**

**device**

**baudrate**

**databits**

**stopbits**

**parity**

**flowcontrol**

Inverter

Danfoss\_INV\_1

1

ComLynx

2000000

PORT1

19200

8

1

none

none

**scan\_rate\_ms**

**retry\_count**

**network**

**subnet**

**address**

60000

3

3

2

163

Add Modbus Slave required information:

**name**

**device\_alias**

**enable**

**protocol**

**timeout\_ms**

**bind\_address**

Modbus Slave

Modbus\_slave

1

Modbus TCP Slave

500000

0.0.0.0

**host**

**port**

**mode**

192.168.1.1

502

tcp

You can find more options and descriptions of the settings in [Device configuration](https://wiki.elseta.com/books/excel-configuration/page/device-configuration "Device configuration") article.

## Configure signals

Add connected inverter signals information. Use inverter manual for information and addresses (**tag\_job\_todo).**

**signal\_name**

**device\_alias**

**signal\_alias**

**enable**

**tag\_type**

**units**

**multiply**

**job\_todo**

**job\_todo**

**number\_type**

Total energy production

Danfoss\_INV\_1

Danfoss\_1

1

Normal

kWh

0,001

08|01|02

NA

UNSIGNED16

...

Where in **job\_todo** *08* is "module id", *01* - "Index", *02* - "SubIndex" of measurements.

**number\_type** can be found in manual as Data type id converted to data type as follow:

0x0: Not defined- Not supported

0x1: Boolean

0x2: Signed 8

0x3: Signed 16

0x4: Signed 32

0x5: Unsigned 8

0x6: Unsigned 16

0x7: Unsigned 32

0x8: Float

0x9: Visible string - Not supported

0xA: Packed bytes - Not supported

0xB: Packed words - Not supported

0xC - 0xF: Reserved- Not supported

Add Modbus slave signals information

**signal\_name**

**device\_alias**

**signal\_alias**

**source\_device\_alias**

**source\_signal\_alias**

**enable**

**tag\_type**

**units**

**multiply**

Total energy production

Modbus\_slave

Modbus\_1

Danfoss\_INV\_1

Danfoss\_1

1

Normal

kWh

1.0

**common\_address**

**function**

**info\_address**

**number\_type**

**size**

1

3

1

UNSIGNED16

1

Use measurements from inverter as a source to be forwarded.

You can find more options and descriptions of the settings in [Signals sheet](https://wiki.elseta.com/books/excel-configuration/page/signals-sheet "Signals sheet") article.

## Upload configuration

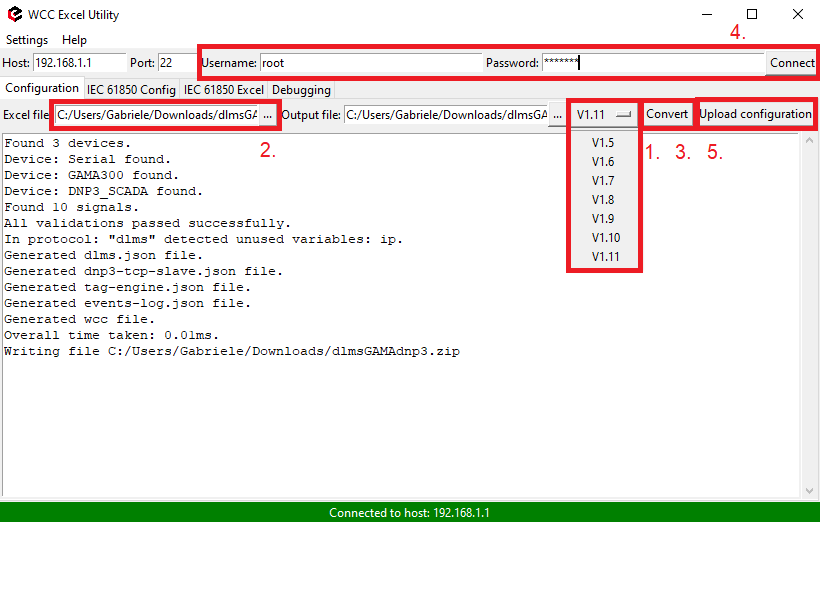

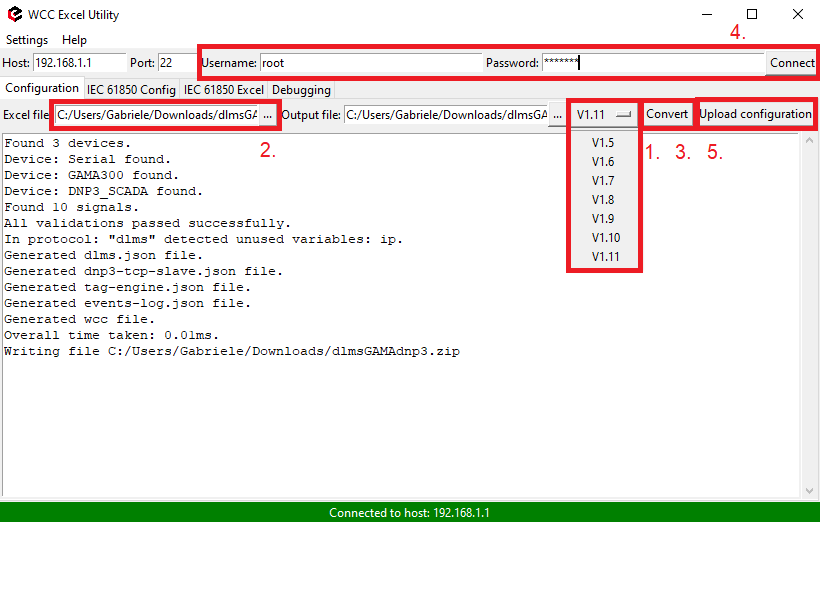

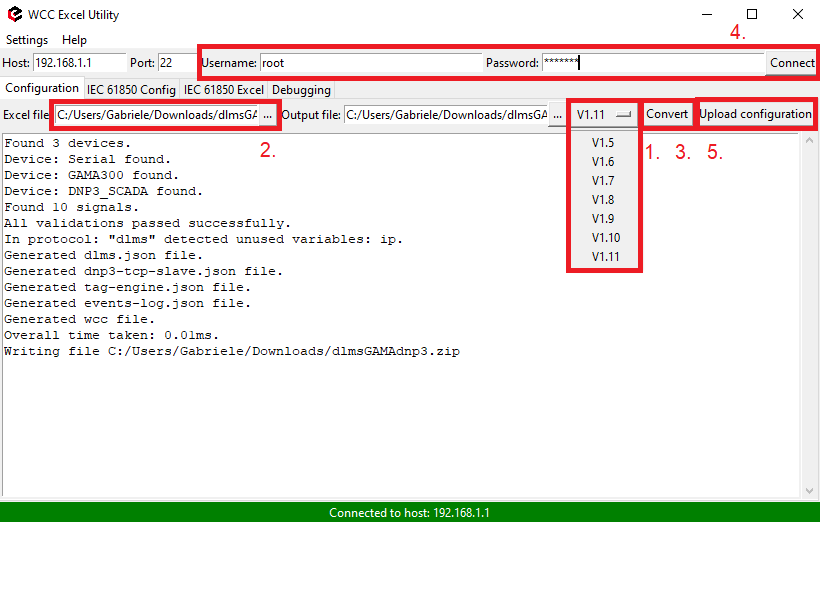

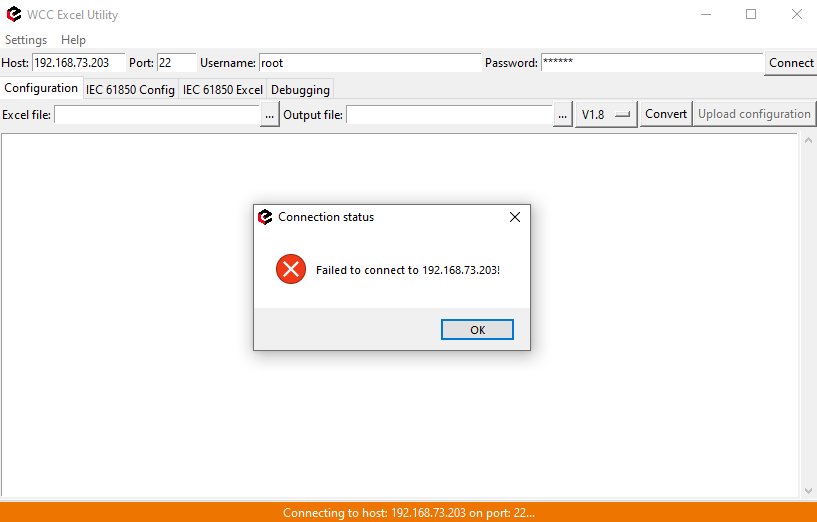

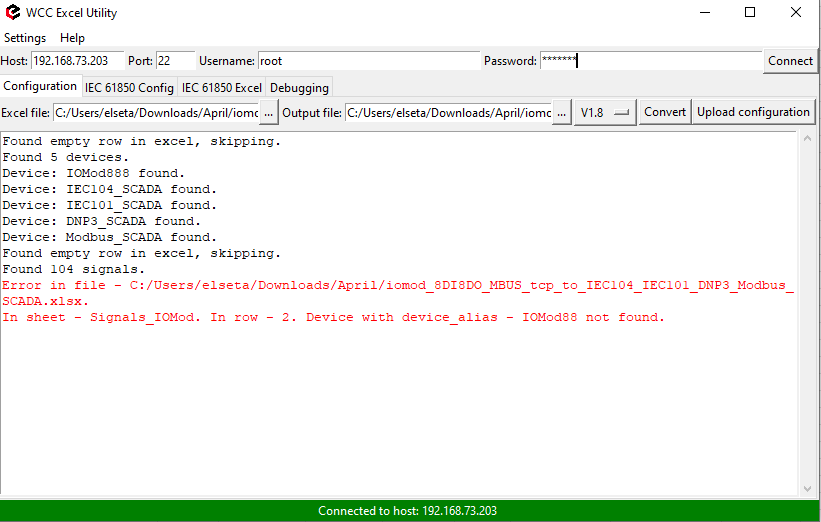

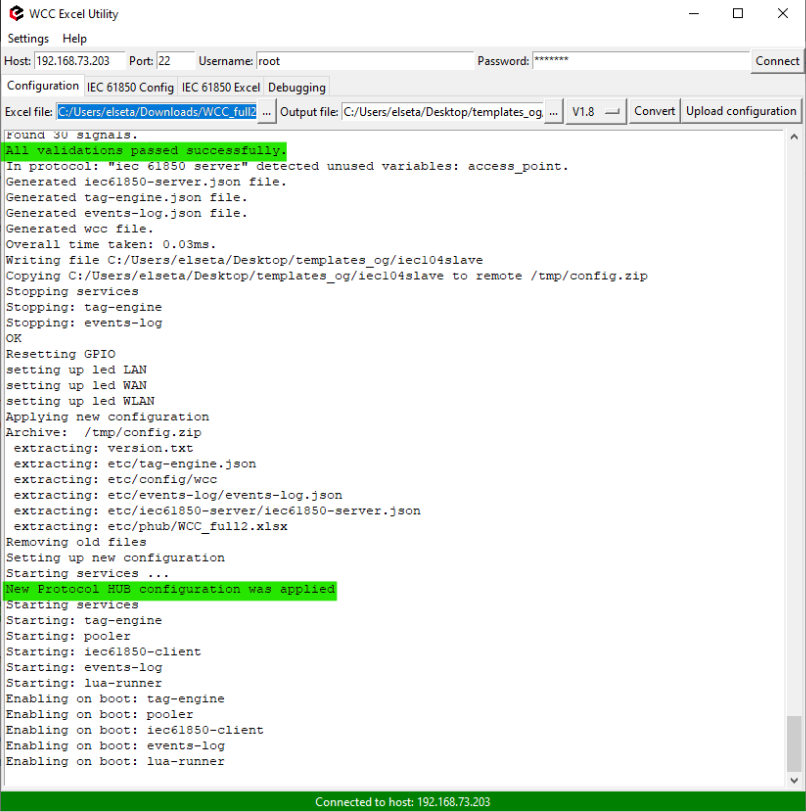

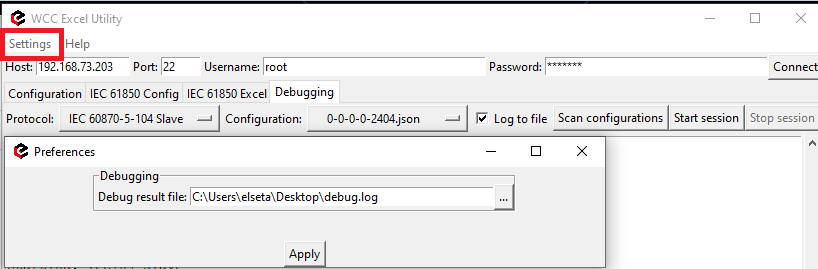

After configuring all devices and signals, follow these steps to check and upload configuration using WCC Excel Utility:

1. [Download ](https://wiki.elseta.com/books/wcclite-downloads/page/firmware-and-tools)and run WCC Excel Utility;

2. Select Excel file from your computer and click *Convert*;

3. Check if no events in red color occur. If so, edit Excel file according to event text and repeat Step 2;

4. Enter Host and credentials of WCC Lite and click *Upload configuration.*

Another method to upload the configuration is via the web interface:

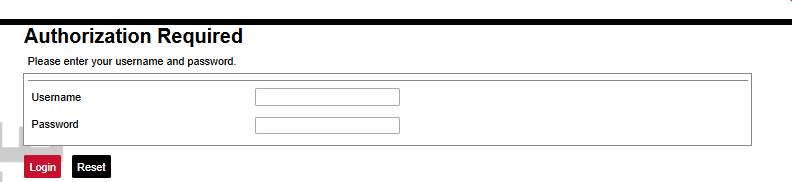

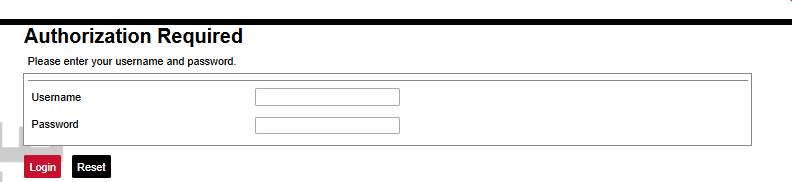

1. Access the WCC Lite interface via your browser:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135286847.png)

2. Upload the Excel configuration:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135363443.png)

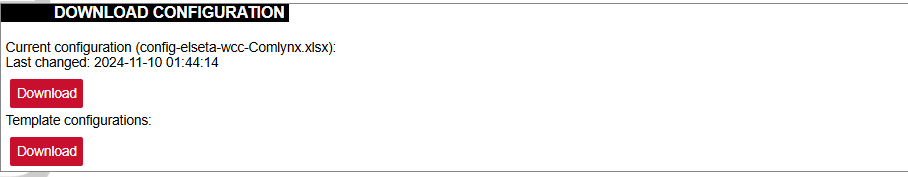

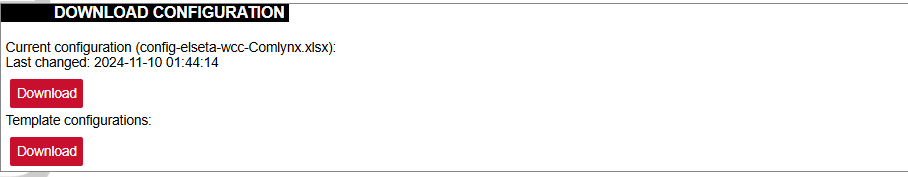

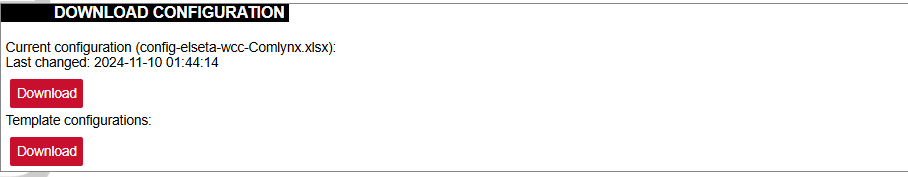

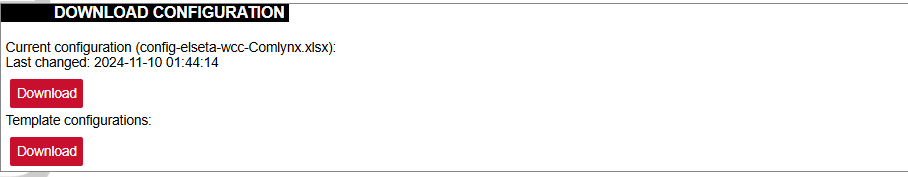

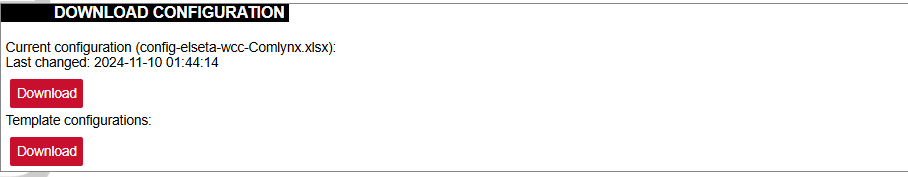

3. After a successful upload, the configuration will appear under the **DOWNLOAD CONFIGURATION** tab:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135451404.png)

4. If any errors occur during the upload, follow the error messages, fix them along Excel utility guidelines.

## Files

1. Danfoss inverter manual - Accessing Inverter Parameters via RS485 using the ComLynx protocol [Download](https://wiki.elseta.com/attachments/4)

2. WCC Excel Utility [Download](https://wiki.elseta.com/books/wcclite-downloads/page/firmware-and-tools)

3. Example of configuration file [Download](https://wiki.elseta.com/attachments/629)

# DLMS Serial to IEC104 protocol conversion

## Description

The article describes WCC Lite configuration steps to enable DLMS Serial protocol conversion to IEC 60870-5-104.

[](https://wiki.elseta.com/uploads/images/gallery/2023-05/image-1685538397956.png)

Fig 1.

## First steps

Before you begin, make sure you have completed all physical installation work according to the manufacturer's installation instructions.Set up your computer and connect Ethernet cable to WCC Lite ETH0 port. Login with default credentials and setup basic required settings (name, network, users, etc.). You can find configuration tutorials in [How to](https://wiki.elseta.com/books/how-to) articles.To prepare configuration fill information in both - [Devices ](https://wiki.elseta.com/books/how-to/page/dlms-serial-to-iec104-protocol-conversion#bkmrk-configure-devices)and [Signals](https://wiki.elseta.com/books/how-to/page/dlms-serial-to-iec104-protocol-conversion#bkmrk-configure-signals) sheets:

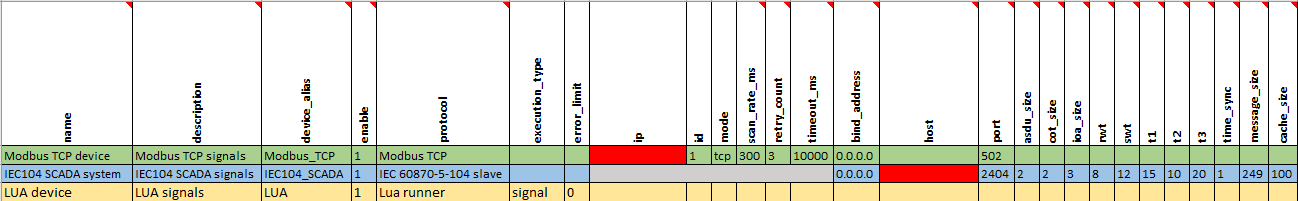

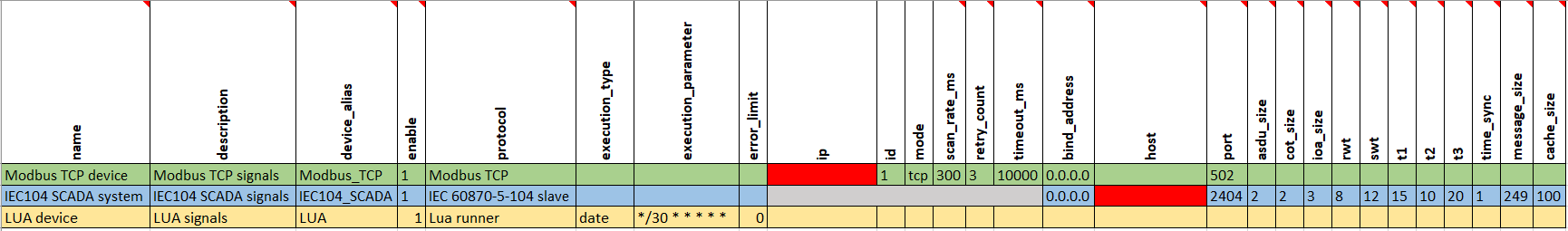

## Configure devices

##### Add connected Gama meter with **DLMS Serial** protocol required information:

**name**

**description**

**device\_alias**

**enable**

**protocol**

**serial\_number**

**device**

**databits**

**stopbits**

From Gama Meter

Elgama Gama 300

GAMA300

1

DLMS

2250259

PORT1

8

1

**baudrate**

**parity**

**flowcontrol**

**logical\_address**

**address\_size**

**client\_address**

**type**

4800

none

none

1

2

32

SN

**mode**

**auth**

DLMS-HDLC

LOW

More information concerning DLMS protocol configuration is provided in [DLMS/COSEM](https://wiki.elseta.com/books/manual-18/page/171-dlmscosem) article.

##### Add SCADA working on **IEC104** protocol required information:

**name**

**device\_alias**

**enable**

**protocol**

**bind\_address**

**host**

**port**

To SCADA

IEC104\_SCADA

1

IEC 60870-5-104 slave

0.0.0.0

192.168.1.10 192.168.71.1

2404

**asdu\_size**

**cot\_size**

**ioa\_size**

**rwt**

**swt**

**t1**

**t2**

**t3**

2

2

3

8

12

45

30

200

**time\_sync**

**message\_size**

**cache\_size**

1

249

100

More information concerning IEC104 protocol configuration is provided in [IEC 60870-5-104 Slave](https://wiki.elseta.com/books/manual-18/page/146-iec-60870-5-104-slave) article.

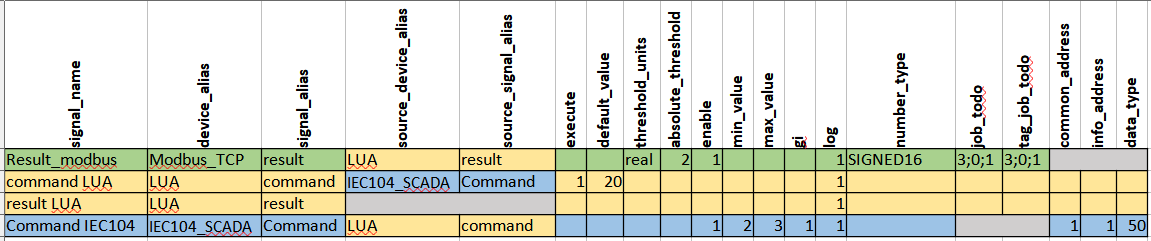

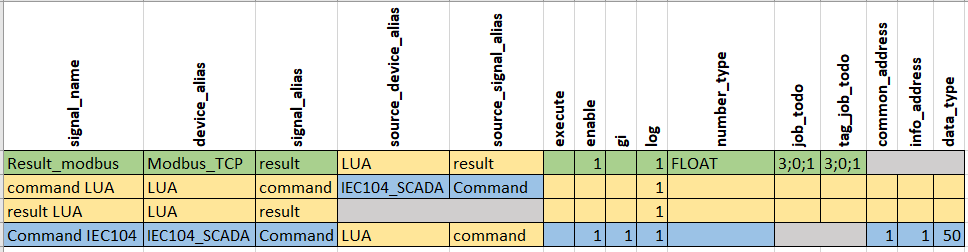

## Configure signals

Add connected meter measurements information.

**signal\_name**

**device\_alias**

**signal\_alias**

**obis\_job**

Voltage

GAMA300

L3\_U

1.0.72.7.0.255

Frequency

GAMA300

F

1.0.14.7.0.255

**obis\_job** - Objects are identified with the help of OBIS (Object Identification System) codes.

1. The first number of OBIS code defines the media (energy type) to which the metering is related. Nonmedia related information is handled as abstract data. For example both obis\_jobs in the table above starts with numbers 1 which stands for "Electricity related objects".

2. The second number defines the channel number, i.e. the number of the input of a metering equipment having several inputs for the measurement of energy of the same or different types (e.g. in data concentrators, registration units). Data from different sources can thus be identified. The definitions for this value group are independent from the value of the first number. In both obis\_jobs from the table above second number is set to zero which means that no channel is specified.

3. The third number defines the abstract or physical data items related to the information source concerned, for example current, voltage, power, volume, temperature. The definitions depend on the value of the first number. For example in obis\_jobs from the table above number 72 means voltage L3 and number 14 means frequency.

4. The forth number defines types, or the result of the processing of physical quantities identified with the numbers 1 and 3, according to various specific algorithms. The algorithms can deliver energy and demand quantities as well as other physical quantities. In both obis\_jobs from the table above forth number is set to 7 which stands for "Instantaneous value".

5. The value of the fifth number defines further processing or classification of quantities identified by numbers 1 to 4. In case of the first obis\_job number 0 means that all harmonics of the signal along with its fundamental frequency are going to be taken into consideration.

6. The value of the sixth number defines the storage of data, identified by numbers 1 to 5, according to different billing periods. Where this is not relevant, this value group can be used for further classification. In both obis\_jobs from the table above last number is set to 255 which means that data is not used.

Add **IEC104 Slave** signals information:

**signal\_name**

**device\_alias**

**signal\_alias**

**source\_device\_alias**

**source\_signal\_alias**

**enable**

IEC104 SCADA V

IEC104\_SCADA

IEC104\_SCADA\_V\_L3\_N

GAMA300

L3\_U

1

IEC104 SCADA F

IEC104\_SCADA

IEC104\_SCADA\_Freq

GAMA300

F

1

**log**

**gi**

**common\_address**

**info\_address**

**data\_type**

1

1

1

101

36

1

1

1

104

36

For more detailed DLMS protocol communication analysis Gurux DLMS Director application can be used.

## Upload configuration

After configuring all devices and signals, follow these steps to check and upload configuration using WCC Excel Utility:

1. [Download ](https://wiki.elseta.com/books/wcclite-downloads/page/firmware-and-tools)and run WCC Excel Utility;

2. Select Excel file from your computer and click *Convert*;

3. Check if no events in red color occur. If so, edit Excel file according to event text and repeat Step 2;

4. Enter Host and credentials of WCC Lite and click *Upload configuration.*

Another method to upload the configuration is via the web interface:

1. Access the WCC Lite interface via your browser:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135286847.png)

2. Upload the Excel configuration:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135363443.png)

3. After a successful upload, the configuration will appear under the **DOWNLOAD CONFIGURATION** tab:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135451404.png)

4. If any errors occur during the upload, follow the error messages, fix them along Excel utility guidelines.

## Files

1. WCC Excel Utility [Download](https://wiki.elseta.com/books/wcclite-downloads/page/firmware-and-tools)

2. Example of configuration file [Download](https://wiki.elseta.com/attachments/104)

# DLMS TCP to DNP3 protocol conversion

## Setup

The article describes WCC Lite configuration steps to enable DLMS tcp protocol conversion to DNP3.

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690294047661.png)

Fig 1. Connection scheme.

Before you begin, make sure you have completed all physical installation work according to the manufacturer's installation instructions.Set up your computer and connect the Ethernet cable to the WCC Lite ETH0 port. Log in with default credentials and set up basic required settings (name, network, users, etc.). You can find configuration tutorials in [How to](https://wiki.elseta.com/books/how-to) articles.To prepare the configuration, fill information in both the [Devices ](https://wiki.elseta.com/books/how-to/page/dlms-tcp-to-dnp3-protocol-conversion#bkmrk-configure-devices)and [Signals](https://wiki.elseta.com/books/how-to/page/dlms-tcp-to-dnp3-protocol-conversion#bkmrk-configure-signals) sheets:

## Configuring Devices

##### Add a connected Gama meter with the **DLMS TCP** protocol required information:

**name**

**description**

**device\_alias**

**enable**

**protocol**

**serial\_number**

**port**

From Gama Meter

Elgama Gama 300

GAMA300

1

DLMS

2393020

4059

**ip**

**logical\_address**

**address\_size**

**client\_address**

**type**

**mode**

**auth**

**password**

192.168.1.2

1

2

32

LN

DLMS-WRAPPER

LOW

00000002

More information concerning DLMS protocol configuration is provided in the [DLMS/COSEM](https://wiki.elseta.com/books/manual-18/page/171-dlmscosem) article.

##### Add the SCADA working on the **DNP3** protocol required information:

**name**

**device\_alias**

**enable**

**protocol**

**mode**

**host**

**bind\_address**

DNP3 SCADA system

DNP3\_SCADA

1

DNP3 TCP slave

TCP

192.168.1.215

0.0.0.0

**port**

destination\_address

source\_address

unsol\_classes

20000

10

1

1,2,3

More information concerning DNP3 protocol configuration is provided in the [DNP 3.0 Slave](https://wiki.elseta.com/books/manual-18/page/123-dnp-30-slave) article.

## Configuring Signals

Add connected meter measurements information.

**signal\_name**

**device\_alias**

**signal\_alias**

**obis\_job**

Voltage L3-N

GAMA300

L3\_U

1.0.72.7.0.255

Frequency

GAMA300

F

1.0.14.7.0.255

Current L3

GAMA300

L3-I

1.0.71.7.0.255

Absolute active instantaneous power

GAMA300

P

1.0.15.7.0.255

**Obis\_job** - Objects are identified with the help of OBIS (Object Identification System) codes.

1. The first number of the OBIS code defines the media (energy type) to which the metering is related. Non-media-related information is handled as abstract data. For example, both obis\_jobs in the table above start with number 1, which stands for "Electricity related objects".

2. The second number defines the channel number, i.e. the number of the input of a metering equipment having several inputs for the measurement of energy of the same or different types (e.g. in data concentrators, registration units). Data from different sources can thus be identified. The definitions for this value group are independent of the value of the first number. In both obis\_jobs from the table above second number is set to zero, which means that no channel is specified.

3. The third number defines the abstract or physical data items related to the information source concerned, for example, current, voltage, power, volume, temperature. The definitions depend on the value of the first number. For example, in obis\_jobs from the table above, the number 72 means voltage L3, and the number 14 means frequency.

4. The fourth number defines types, or the result of the processing of physical quantities identified with the numbers 1 and 3, according to various specific algorithms. The algorithms can deliver energy and demand quantities as well as other physical quantities. In both obis\_jobs from the table above fourth number is set to 7, which stands for "Instantaneous value".

5. The value of the fifth number defines further processing or classification of quantities identified by numbers 1 to 4. In case of the first obis\_job number 0 means that all harmonics of the signal along with its fundamental frequency are going to be taken into consideration.

6. The value of the sixth number defines the storage of data, identified by numbers 1 to 5, according to different billing periods. Where this is not relevant, this value group can be used for further classification. In both obis\_jobs from the table above last number is set to 255, which means that the data is not used.

Add **DNP3 Slave** signals information:

**signal\_name**

**device\_alias**

**signal\_alias**

**source\_device\_alias**

**source\_signal\_alias**

**enable**

DNP3 SCADA V

DNP3\_SCADA

DNP3\_SCADA\_V\_L3\_N

GAMA300

L3\_U

1

DNP3 SCADA F

DNP3\_SCADA

DNP3\_SCADA\_Freq

GAMA300

F

1

DNP3 SCADA A

DNP3\_SCADA

DNP3\_SCADA\_A\_L3

GAMA300

L3\_I

1

DNP3 SCADA KW

DNP3\_SCADA

DNP3\_SCADA\_P

GAMA300

P

1

**index**

**signal\_type**

**static\_variation**

**event\_variation**

**class\_num**

1

analog

1

3

2

2

analog

1

3

2

3

analog

1

3

2

4

analog

1

3

2

For more detailed DLMS protocol communication analysis Gurux DLMS Director application can be used.

## Uploading the Configuration

After configuring all devices and signals, follow these steps to check and upload the configuration using the WCC Excel Utility:

1. [Download ](https://wiki.elseta.com/books/wcclite-downloads/page/firmware-and-tools)and run WCC Excel Utility.

2. Select the firmware version from the drop-down menu.

3. Select the Excel file from your computer and click *Convert*.

4. Check if no events in red color occur. If so, edit the Excel file according to the event text and repeat Step 2.

5. Enter the Host and credentials of WCC Lite, click connect and then *Upload configuration.*

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1744036903331.png)

Another method to upload the configuration is via the web interface:

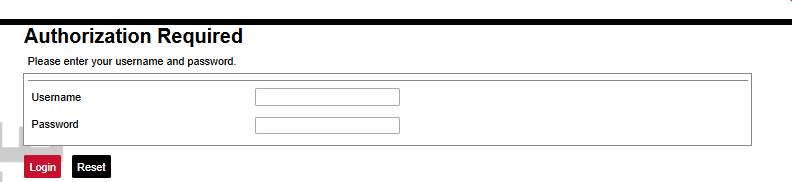

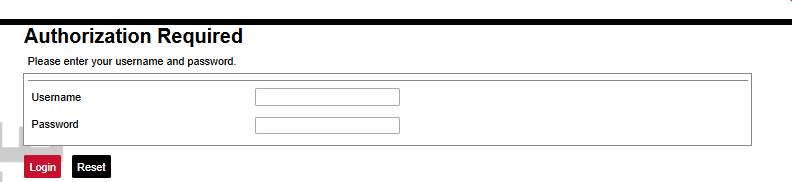

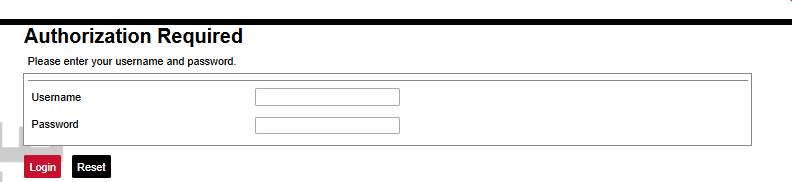

1. Access the WCC Lite interface via your browser. The default IP address is 192.168.1.1. Enter credentials:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135286847.png)

2. Upload the Excel configuration:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135363443.png)

3. After a successful upload, the configuration will appear under the **DOWNLOAD CONFIGURATION** tab:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135451404.png)

4. If any errors occur during the upload, follow the error messages, fix them according to Excel utility guidelines.

## Files

1. WCC Excel Utility [Download](https://wiki.elseta.com/attachments/655)

2. Example of configuration file [Download](https://wiki.elseta.com/attachments/656)

# Modbus RTU to IEC104 protocol conversion

## Setup

This article describes WCC Lite configuration steps to enable Modbus TCP protocol conversion to IEC 104.

[](https://wiki.elseta.com/uploads/images/gallery/2020-10/image-1602846671040.png)

Before you begin, make sure you have completed all physical installation work according to the manufacturer's installation instructions.

Set up your computer and connect the Ethernet cable to the WCC Lite ETH0 port. Log in with default credentials and set up basic required settings (name, network, users, etc. ). You can find configuration tutorials in [How to](https://wiki.elseta.com/books/how-to) articles.

After setup, download the configuration template from the device (Protocol Hub → Configuration → Template configuration Download)

Or download the configuration example from this article.

To prepare the configuration, fill in the information in both the [Devices ](#bkmrk-configure-devices)and [Signals](#bkmrk-configure-signals) sheets:

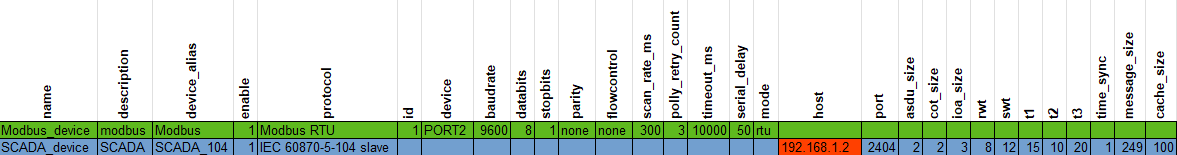

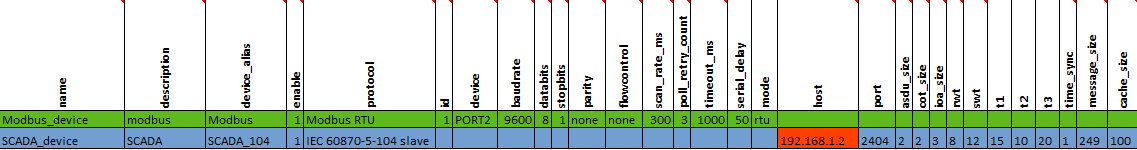

## Configuring Devices

##### Add a connected ABB meter with the Modbus RTU protocol required information:

**name**

**description**

**device\_alias**

**enable**

**protocol**

**id**

**device**

**baudrate**

**databits**

From ABB Meter

ABB B21

B21

1

Modbus RTU

1

PORT2

9600

8

**stopbits**

**parity**

**flowcontrol**

**scan\_rate\_ms**

**serial\_delay**

**retry\_count**

1

none

none

5000

200

3

##### Add SCADA working on IEC104 protocol required information:

**name**

**description**

**device\_alias**

**enable**

**protocol**

**bind\_address**

**host**

**port**

To SCADA

iec104

1

IEC 60870-5-104 slave

0.0.0.0

192.168.1.10 192.168.71.1

2404

**asdu\_size**

**cot\_size**

**ioa\_size**

**rwt**

**swt**

**t1**

**t2**

**t3**

**time\_sync**

**message\_size**

**cache\_size**

2

2

3

8

12

45

30

200

1

249

100

You can find more options and descriptions of the settings in the [Device configuration](https://wiki.elseta.com/books/excel-configuration/page/device-configuration "Device configuration") article.

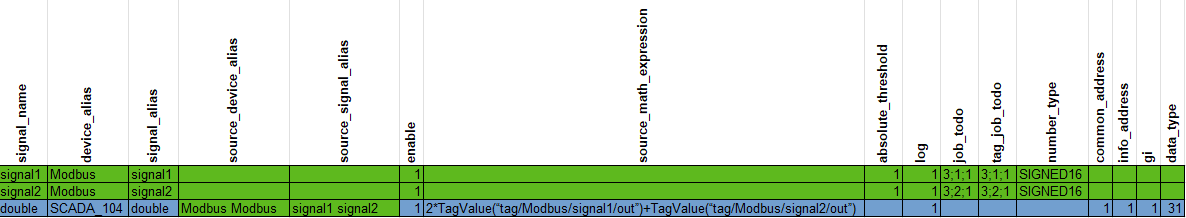

## Configuring Signals

Add connected meter measurements information. Use the meter manual for information and addresses (**tag\_job\_todo).**

**signal\_name**

**device\_alias**

**signal\_alias**

**enable**

**multiply**

**log**

**job\_todo**

**tag\_job\_todo**

**number\_type**

Voltage

B21

U

1

0.1

1

3;23296;2

3;23296;2

UNSIGNED32

Current

B21

I

1

0.01

1

3;23308;2

3;23308;2

UNSIGNED32

Active power

B21

P

1

0.00001

1

3;23316;2

3;23316;2

SIGNED32

Frequency

B21

F

1

0.01

1

3;23340;1

3;23340;1

UNSIGNED16

Power factor

B21

Cos

1

0.001

1

3;23354;1

3;23354;1

SIGNED16

Active import

B21

E

1

0.01

1

3;20480;4

3;20480;4

FLOAT

**job\_todo** -Request to send according to Modbus specification without device address and checksum;

**tag\_job\_todo** - a subset of the **job\_todo** field, exact address of measurement (tag)

Add **IEC104** master signals information:

**signal\_name**

**device\_alias**

**signal\_alias**

**source\_device\_alias**

**source\_signal\_alias**

Voltage

iec104

tag-iec104-1001

B21

U

Current

iec104

tag-iec104-1002

B21

I

Active power

iec104

tag-iec104-1003

B21

P

Frequency

iec104

tag-iec104-1004

B21

F

Power factor

iec104

tag-iec104-1005

B21

Cos

Active import

iec104

tag-iec104-1006

B21

E

**enable**

**log**

**units**

**multiply**

**gi**

**common\_address**

**info\_address**

**data\_type**

1

1

V

1.0

1

1

1001

13

1

1

A

1.0

1

1

1002

13

1

1

kW

1.0

1

1

1003

13

1

1

Hz

1.0

1

1

1004

13

1

1

1.0

1

1

1005

13

1

1

kWh

1.0

1

1

1006

13

## Other examples with the Rail350 meter

The video covers only 1.5 firmware version.

## Uploading the Configuration

After configuring all devices and signals, follow these steps to check and upload the configuration using the WCC Excel Utility:

1. [Download ](https://wiki.elseta.com/books/wcclite-downloads/page/firmware-and-tools)and run WCC Excel Utility.

2. Select the firmware version from the drop-down menu.

3. Select the Excel file from your computer and click *Convert*.

4. Check if no events in red color occur. If so, edit the Excel file according to the event text and repeat Step 2.

5. Enter the Host and credentials of WCC Lite, click connect and then *Upload configuration.*

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1744036903331.png)

Another method to upload the configuration is via the web interface:

1. Access the WCC Lite interface via your browser. The default IP address is 192.168.1.1. Enter credentials:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135286847.png)

2. Upload the Excel configuration:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135363443.png)

3. After a successful upload, the configuration will appear under the **DOWNLOAD CONFIGURATION** tab:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135451404.png)

4. If any errors occur during the upload, follow the error messages, fix them according to Excel utility guidelines.

## Files

1. ABB meter manual [Download](https://search.abb.com/library/Download.aspx?DocumentID=2CMC485004M0201&LanguageCode=en&DocumentPartId=&Action=Launch)

2. WCC Excel Utility [Download](https://wiki.elseta.com/attachments/657)

3. Example of configuration file [Download](https://wiki.elseta.com/attachments/658)

# Modbus RTU to DNP3 protocol conversion

## Setup

The article describes WCC Lite configuration steps to enable Modbus RTU protocol conversion to DNP3 serial.

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1744184546840.png)

Before you begin, make sure you have completed all physical installation work according to the manufacturer's installation instructions.Set up your computer and connect the Ethernet cable to the WCC Lite ETH0 port. Log in with default credentials and set up basic required settings (name, network, users, etc.). You can find configuration tutorials in [How to](https://wiki.elseta.com/books/how-to) articles.To prepare the configuration, fill in the information in both the [Devices ](https://wiki.elseta.com/books/how-to/page/dlms-serial-to-iec104-protocol-conversion#bkmrk-configure-devices)and [Signals](https://wiki.elseta.com/books/how-to/page/dlms-serial-to-iec104-protocol-conversion#bkmrk-configure-signals) sheets:

## Configuring Devices

##### Add a connected ABB meter with the Modbus RTU protocol required information:

**name**

**description**

**device\_alias**

**enable**

**protocol**

**id**

**device**

**baudrate**

**databits**

From ABB Meter

ABB B21

B21

1

Modbus RTU

1

PORT1

9600

8

**stopbits**

**parity**

**flowcontrol**

**scan\_rate\_ms**

**serial\_delay**

**retry\_count**

1

none

none

5000

200

3

##### Add the SCADA working on the DNP3 protocol required information:

**name**

**device\_alias**

**enable**

**protocol**

**mode**

**bind\_address**

DNP3

DNP3\_SCADA

1

DNP3 TCP slave

TCP

0.0.0.0

**host**

**port**

source\_address

unsol\_classes

192.168.1.1

20000

1

1,2,3

You can find more options and descriptions of the settings in the [Device configuration](https://wiki.elseta.com/books/excel-configuration/page/device-configuration "Device configuration") article.

## Configuring Signals

Add connected meter measurements information. Use the meter manual for information and addresses (**tag\_job\_todo).**

**signal\_name**

**device\_alias**

**signal\_alias**

**enable**

**multiply**

**log**

**job\_todo**

**tag\_job\_todo**

**number\_type**

Voltage

B21

U

1

0.1

1

3;23296;2

3;23296;2

UNSIGNED32

Current

B21

I

1

0.01

1

3;23308;2

3;23308;2

UNSIGNED32

Active power

B21

P

1

0.00001

1

3;23316;2

3;23316;2

SIGNED32

Frequency

B21

F

1

0.01

1

3;23340;1

3;23340;1

UNSIGNED16

Power factor

B21

Cos

1

0.001

1

3;23354;1

3;23354;1

SIGNED16

Active import

B21

E

1

0.01

1

3;20480;4

3;20480;4

FLOAT

**job\_todo** -Request to send according to Modbus specification without device address and checksum;

**tag\_job\_todo** - a subset of the **job\_todo** field, exact address of measurement (tag)

Add **DNP3** master signals information:

**signal\_name**

**device\_alias**

**signal\_alias**

**source\_device\_alias**

**source\_signal\_alias**

Voltage

dnp3

dnp3\_1001

B21

U

Current

dnp3

dnp3\_1002

B21

I

Active power

dnp3

dnp3\_1003

B21

P

Frequency

dnp3

dnp3\_1004

B21

F

Power factor

dnp3

dnp3\_1005

B21

Cos

Active import

dnp3

dnp3\_1006

B21

E

**enable**

**log**

**index**

**signal\_type**

**static\_variation**

**event\_variation**

**class\_num**

1

1

1

analog

1

1

13

1

1

2

analog

1

1

13

1

1

3

analog

1

1

13

1

1

4

analog

1

1

13

1

1

5

analog

1

1

13

1

1

6

analog

1

1

13

## Uploading the Configuration

After configuring all devices and signals, follow these steps to check and upload the configuration using the WCC Excel Utility:

1. [Download ](https://wiki.elseta.com/books/wcclite-downloads/page/firmware-and-tools)and run WCC Excel Utility.

2. Select the firmware version from the drop-down menu.

3. Select the Excel file from your computer and click *Convert*.

4. Check if no events in red colour occur. If so, edit the Excel file according to the event text and repeat Step 2.

5. Enter the Host and credentials of WCC Lite, click connect and then *Upload configuration.*

[](https://wiki.elseta.com/uploads/images/gallery/2025-04/image-1744036903331.png)

Another method to upload the configuration is via the web interface:

1. Access the WCC Lite interface via your browser. The default IP address is 192.168.1.1. Enter credentials:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135286847.png)

2. Upload the Excel configuration:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135363443.png)

3. After a successful upload, the configuration will appear under the **DOWNLOAD CONFIGURATION** tab:

[](https://wiki.elseta.com/uploads/images/gallery/2024-12/image-1733135451404.png)

4. If any errors occur during the upload, follow the error messages and fix them according to Excel utility guidelines.

## Files

1. WCC Excel Utility [Download](https://wiki.elseta.com/attachments/660)

2. Example configuration file [Download](https://wiki.elseta.com/attachments/661)

3. ABB meter manual [Download](https://wiki.elseta.com/attachments/662)

# DLMS Serial to IEC61850-server protocol conversion (Wcc Lite FW: 1.7.0)

## Description

The article describes WCC Lite configuration steps to enable DLMS Serial protocol conversion to IEC 61850-server.

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690356504117.png)

Fig 1. Connecting Meter with DLMS serial protocol to Wcc Lite and IEC61850 server

## First steps

Before you begin, make sure you have completed all physical installation work according to the manufacturer's installation instructions.Set up your computer and connect Ethernet cable to WCC Lite ETH0 port. Login with default credentials and setup basic required settings (name, network, users, etc.). You can find configuration tutorials in [How to](https://wiki.elseta.com/books/how-to) articles.To prepare configuration fill information in both - [Devices ](https://wiki.elseta.com/books/how-to/page/dlms-serial-to-iec104-protocol-conversion#bkmrk-configure-devices)and [Signals](https://wiki.elseta.com/books/how-to/page/dlms-serial-to-iec104-protocol-conversion#bkmrk-configure-signals) sheets:

## Configure devices (excel "Devices" sheet)

##### Add required information for connected Gama meter with **DLMS Serial** protocol:

**name**

**description**

**device\_alias**

**protocol**

**serial\_number**

**device**

**databits**

**stopbits**

**baudrate**

**parity**

DLMS Serial

DLMS Serial

DLMS\_Meter

DLMS

2250259

PORT1

8

1

4800

none

**flowcontrol**

**enable**

**auth**

**logical\_address**

**address\_size**

**client\_address**

**type**

**mode**

none

1

LOW

1

2

32

SN

DLMS-HDLC

More information concerning DLMS protocol configuration is provided in [DLMS/COSEM](https://wiki.elseta.com/books/manual-18/page/171-dlmscosem) article.

#####

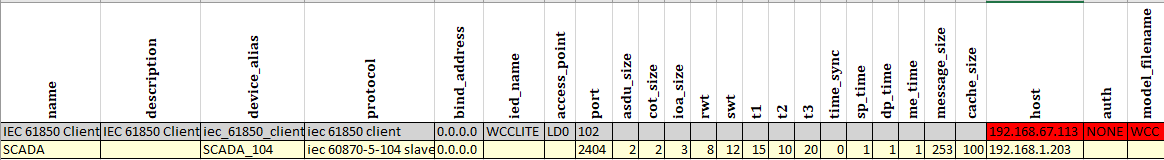

##### Add **IEC 61850 server** protocol required information:

**name**

**description**

**device\_alias**

**protocol**

**bind\_address**

IEC 61850 Server

IEC 61850 Server

iec\_61850\_server

iec 61850 server

0.0.0.0

**ied\_name**

**access\_point**

**port**

**auth**

**host**

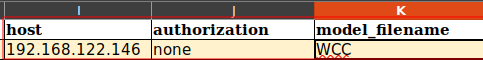

**model\_filename**

WCCLITE

LD0

102

NONE

192.168.1.2

WCC

More information concerning IEC 61850 server protocol configuration is provided in [IEC 61850 server](https://wiki.elseta.com/books/manual-18/page/152-iec-61850-server) article.

## Configure signals (Excel "Signals" sheet)

The signals for all devices can be separated to different excel sheets for different device or listed in one excel sheet. In this case signals will be separated to **SignalsDLMS** and **SignalsIEC61850** excel sheets. Make sure that these excel sheet names for different device signals always must start with word **Signals.** The example template for this case is added at the end of this article.

#### Add signals information for connected meter with DLMS Serial protocol

(Excel **SignalsDLMS** sheet):

**signal\_name**

**device\_alias**

**signal\_alias**

**obis\_job**

Voltage L1-N

DLMS\_Meter

Voltage\_L1-N

1.0.32.7.0.255

Voltage L2-N

DLMS\_Meter

Voltage\_L2-N

1.0.52.7.0.255

Voltage L3-N

DLMS\_Meter

Voltage\_L3-N

1.0.72.7.0.255

Frequency

DLMS\_Meter

Frequency

1.0.14.7.0.255

Current L3

DLMS\_Meter

Current\_L3

1.0.71.7.0.255

**obis\_job** - Objects are identified with the help of OBIS (Object Identification System) codes.

1. The first number of OBIS code defines the media (energy type) to which the metering is related. Nonmedia

related information is handled as abstract data. For example all obis\_jobs in the table above starts with numbers 1 which stands for "Electricity related objects".

2. The second number defines the channel number, i.e. the number of the input of a metering

equipment having several inputs for the measurement of energy of the same or different types

(e.g. in data concentrators, registration units). Data from different sources can thus be

identified. The definitions for this value group are independent from the value of the first number. In all obis\_jobs from the table above second number is set to zero which means that no channel is specified.

3. The third number defines the abstract or physical data items related to the information

source concerned, for example current, voltage, power, volume, temperature. The definitions

depend on the value of the first number. For example in obis\_jobs from the table above number 72 means voltage L3 and number 14 means frequency.

4. The forth number defines types, or the result of the processing of physical quantities

identified with the numbers 1 and 3, according to various specific algorithms. The

algorithms can deliver energy and demand quantities as well as other physical quantities. In all obis\_jobs from the table above forth number is set to 7 which stands for "Instantaneous value".

5. The value of the fifth number defines further processing or classification of quantities identified by numbers 1 to 4. In case of the first obis\_job number 0 means that all harmonics of the signal along with its fundamental frequency are going to be taken into consideration.

6. The value of the sixth number defines the storage of data, identified by numbers 1 to 5, according to

different billing periods. Where this is not relevant, this value group can be used for further

classification. In all obis\_jobs from the table above last number is set to 255 which means that data is not used.

#### Add signals information for **IEC 61850 server** (Excel **SignalsIEC61850** sheet):

**signal\_name**

**device\_alias**

**signal\_alias**

**source\_device\_alias**

**source\_signal\_alias**

LD0\_\_GGIO\_5\_AnIn1\_mag.f

iec\_61850\_server

LD0\_\_GGIO\_5\_AnIn1\_mag.f

DLMS\_Meter

Voltage\_L1-N

LD0\_\_GGIO\_5\_AnIn2\_mag.f

iec\_61850\_server

LD0\_\_GGIO\_5\_AnIn2\_mag.f

DLMS\_Meter

Voltage\_L2-N

LD0\_\_GGIO\_5\_AnIn3\_mag.f

iec\_61850\_server

LD0\_\_GGIO\_5\_AnIn3\_mag.f

DLMS\_Meter

Voltage\_L3-N

LD0\_\_GGIO\_5\_AnIn4\_mag.f

iec\_61850\_server

LD0\_\_GGIO\_5\_AnIn4\_mag.f

DLMS\_Meter

Frequency

LD0\_\_GGIO\_5\_AnIn5\_mag.f

iec\_61850\_server

LD0\_\_GGIO\_5\_AnIn5\_mag.f

DLMS\_Meter

Current\_L3

**ld\_instance**

**ln\_class**

**ln\_instance**

**cdc**

**data\_object**

**da\_fc**

**number\_type**

**da\_value**

**Log**

LD0

GGIO

5

MV

AnIn1

MX

FLOAT32

mag.f

1

LD0

GGIO

5

MV

AnIn2

MX

FLOAT32

mag.f

1

LD0

GGIO

5

MV

AnIn3

MX

FLOAT32

mag.f

1

LD0

GGIO

5

MV

AnIn4

MX

FLOAT32

mag.f

1

LD0

GGIO

5

MV

AnIn5

MX

FLOAT32

mag.f

1

From the table above it can be seen that IEC 61850 server signals has **source\_device\_alias** and **source\_signal\_alias** in which device\_alias and signal\_alias of DLMS meter signals are described. That is how DLMS meter signals are linked to IEC61850 server signals, so the measurements of the DLMS meter could be transported to IEC 61850 server.

For more detailed DLMS protocol communication analysis Gurux DLMS Director application can be used.

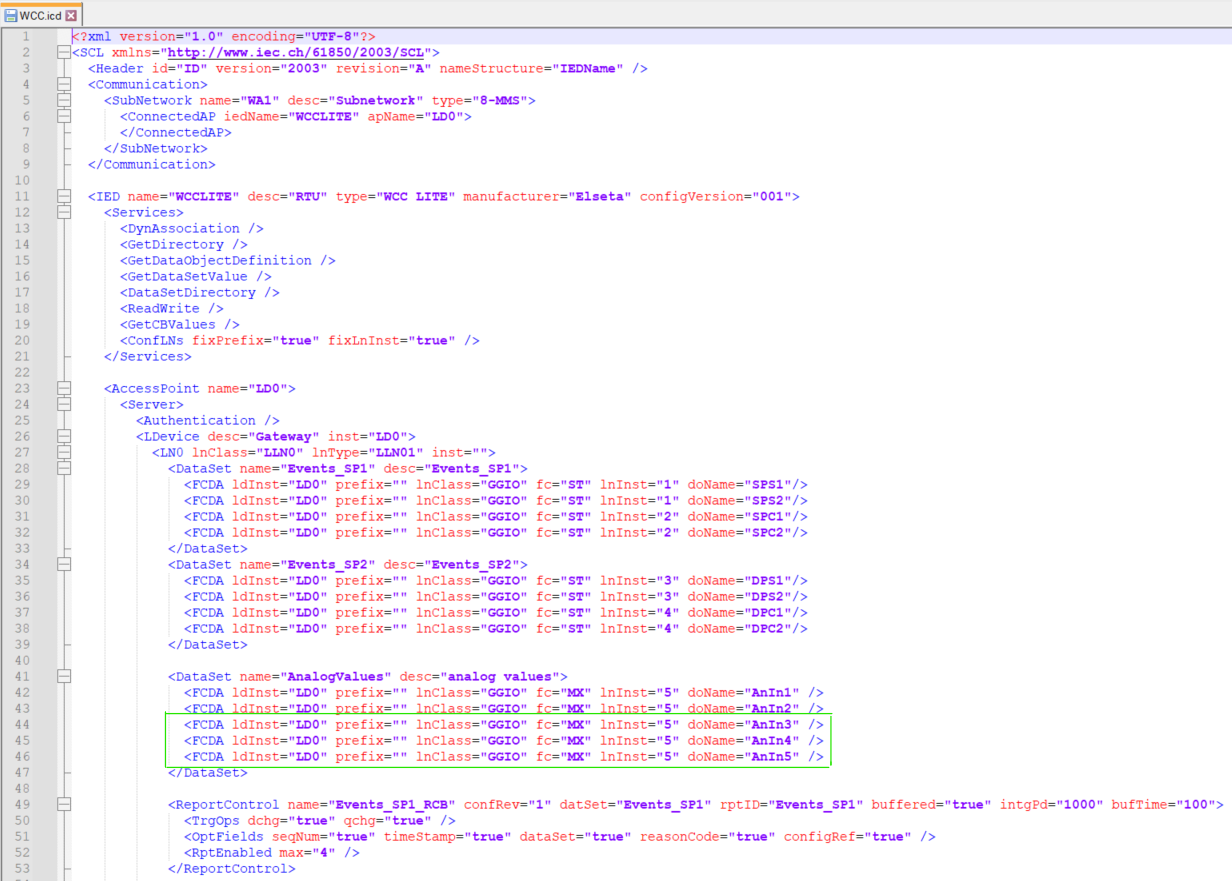

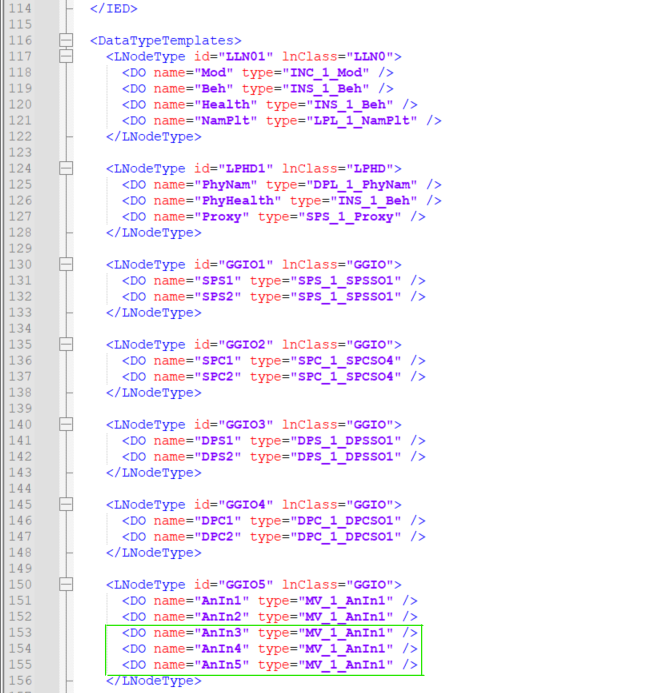

## ICD file for IEC 61850 server

IED Capability Description (ICD) files are a specific type of Substation Configuration Language (SCL) file, containing a generic description of the whole capability range of a given device, including the functions and objects it can support. These ICD files can be found on internet, edited and adapted for current project. In this case the ICD file with 2 analog signals was edited, so it could have 5 analog signals for DLMS measurements. For that purpose, 3 additional signals was described in ICD file, so 5 analog signals could be linked with signals from DLMS. The ICD file and added signals are shown in Fig. 2. If it is needed to have more analog or other type of signals, the ICD file must be analyzed and signals added to the correct place of the file.

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690292826983.png)[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690292954514.png)

Fig. 2 Editing the ICD file

This ICD file will be used for creating the IEC 61850 server model file, which later will be uploaded to Wcc Lite. Also the ICD file will be uploaded to IEDscout app, for simulating the client. Other apps for simulation of client can be used as well.

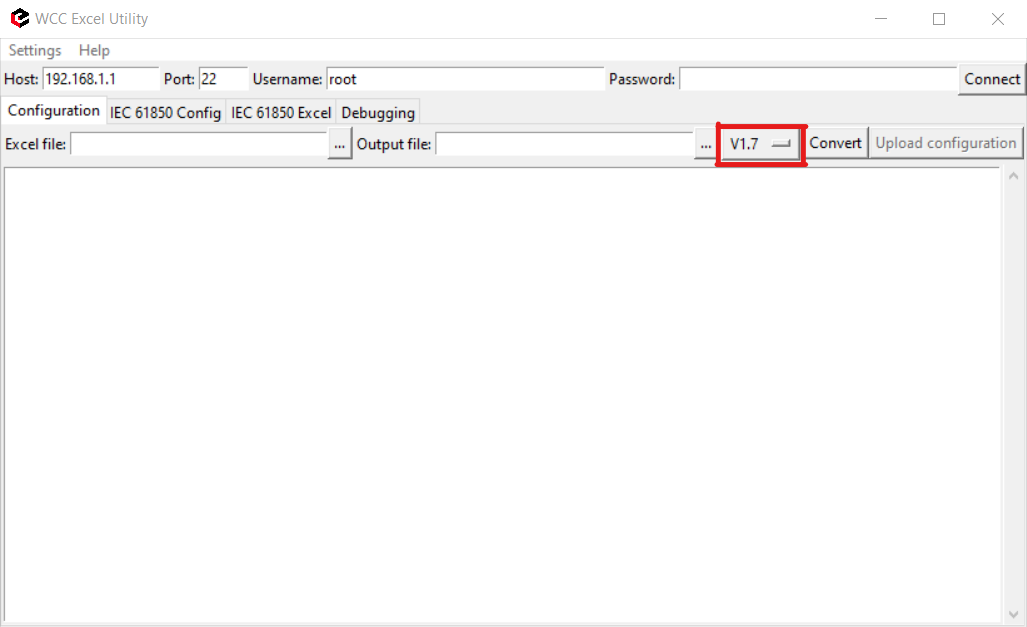

## Generating Server Model file for Wcc Lite

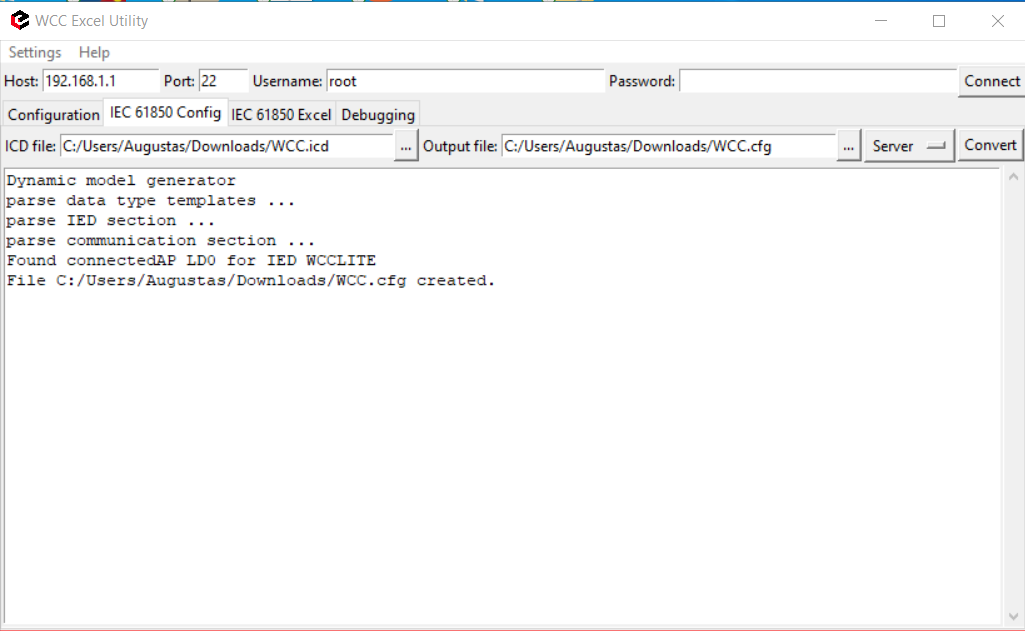

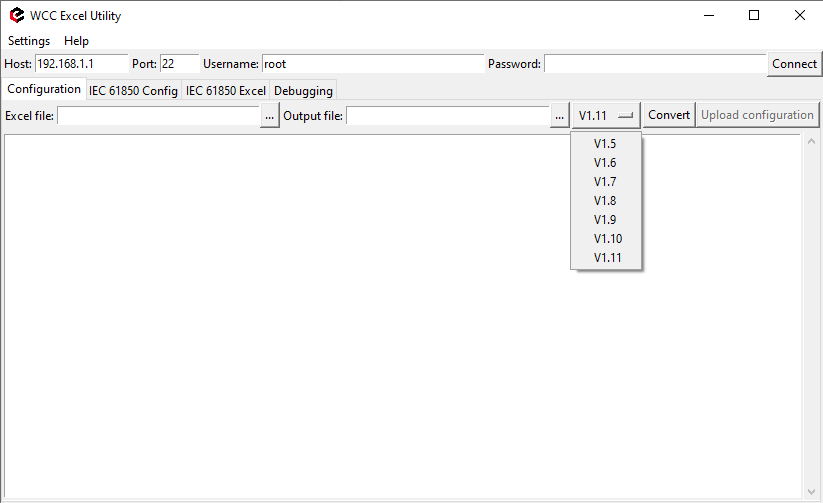

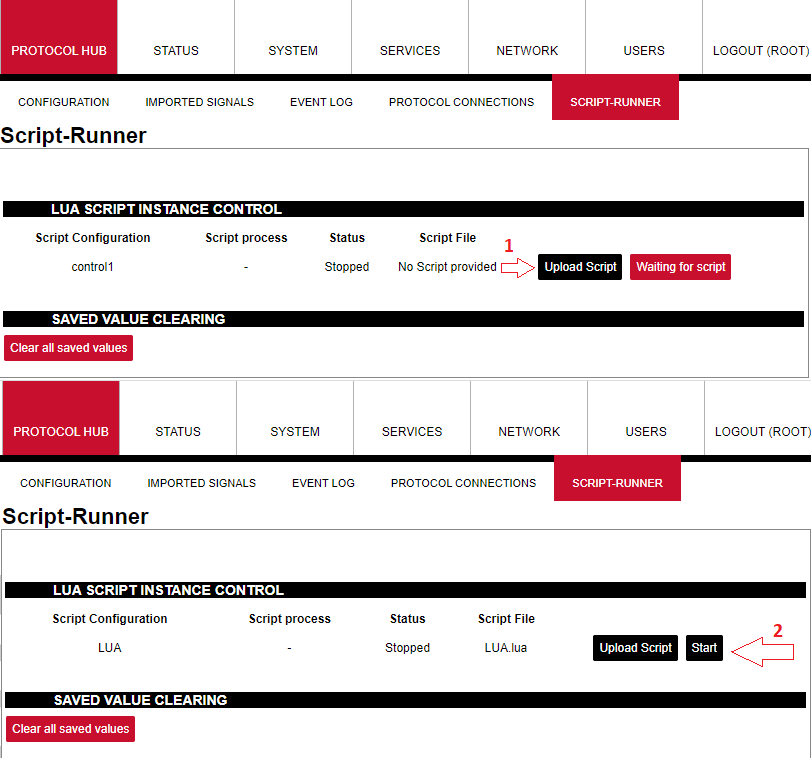

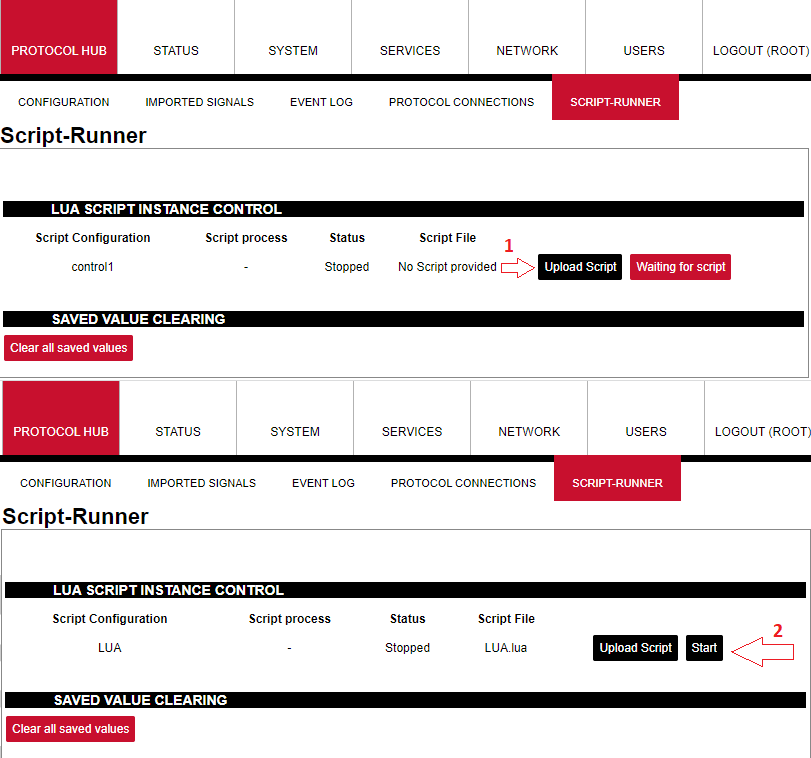

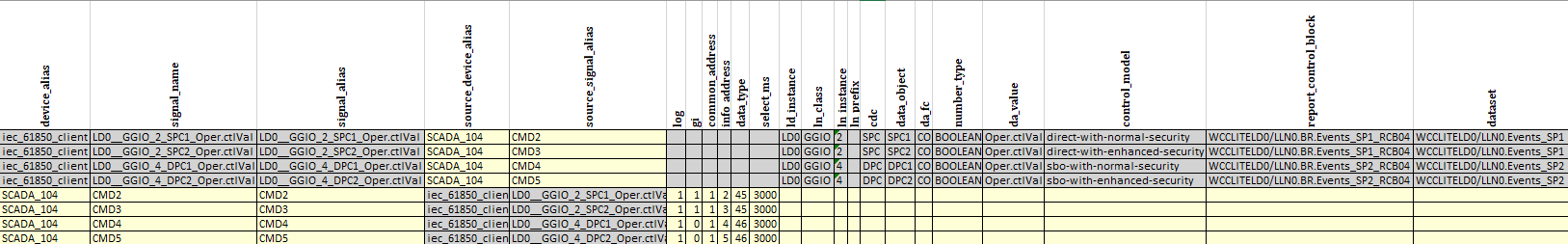

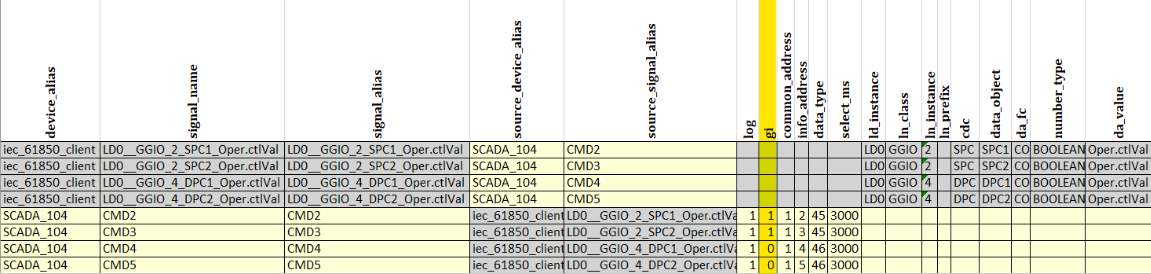

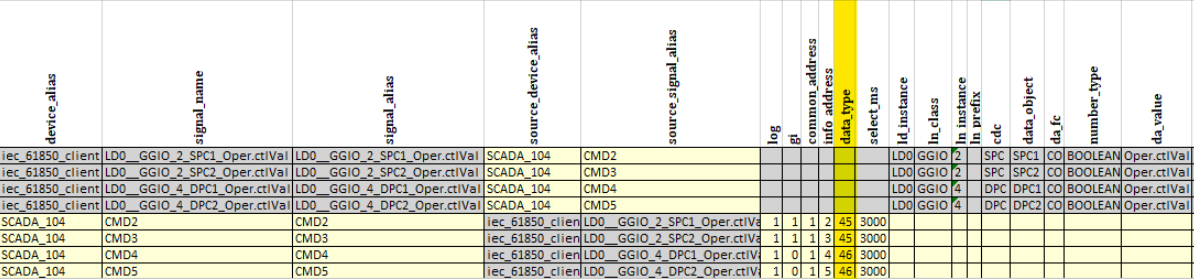

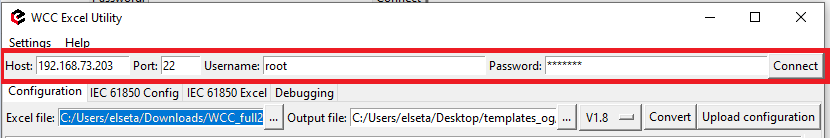

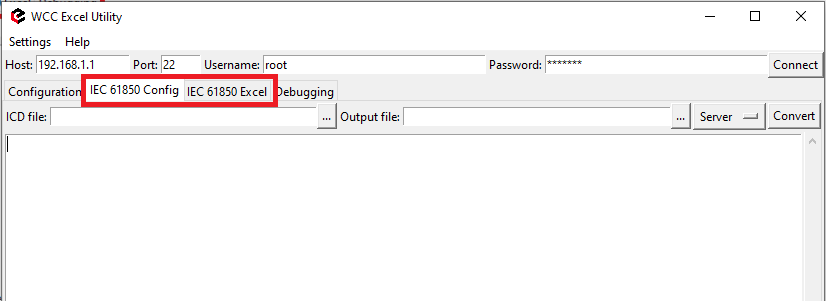

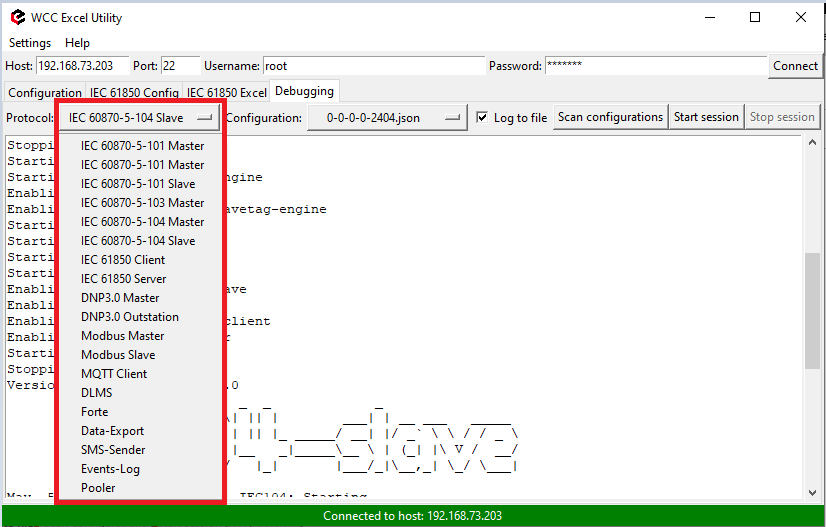

For this step, Wcc Excel Utility app will be used. Firstly open Wcc Excel Utility app and choose **version 1.7** in "Configuration" tab**.**

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690294044910.png)

Fig. 3 Choosing the right version

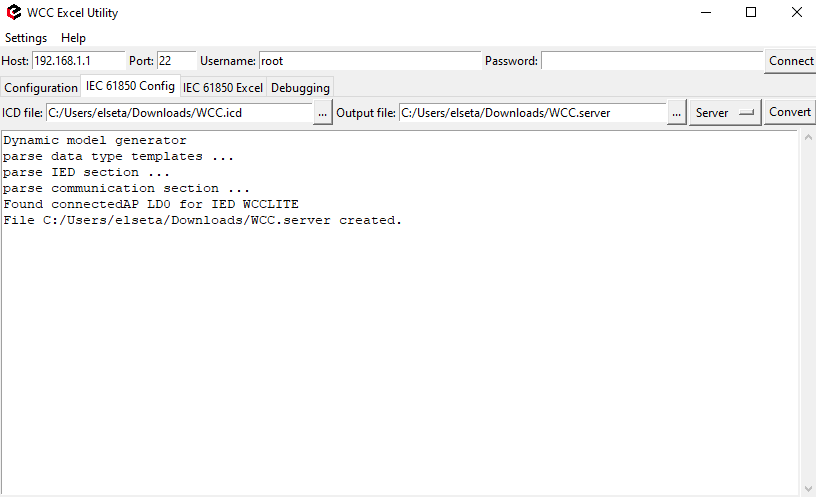

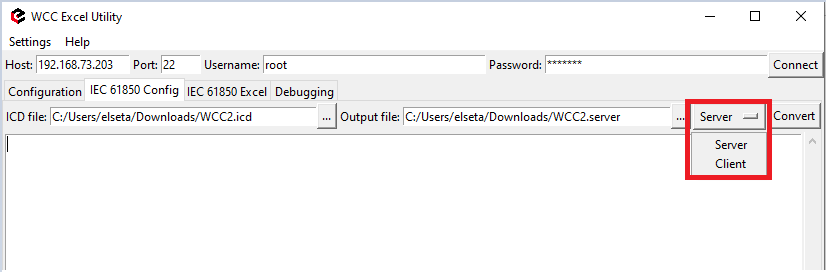

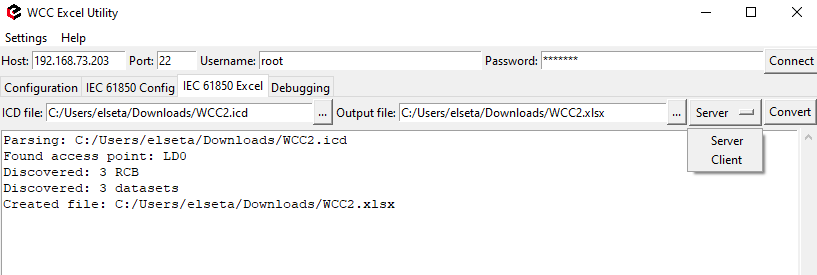

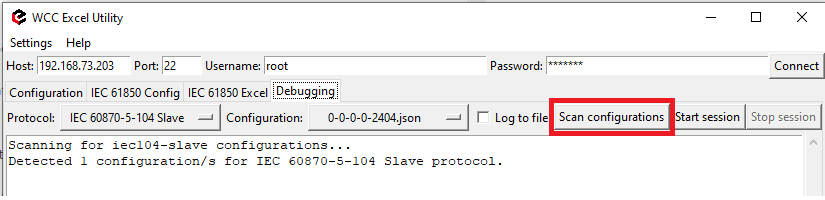

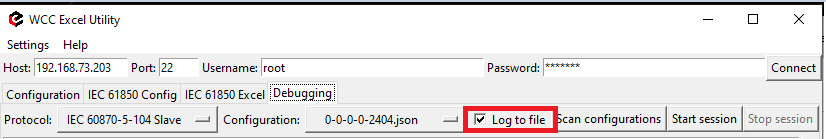

Second step is to go to IEC61850 Config tab, choose the ICD file that is needed and Output file directory of Server Model file. The name of output file should be the same as the name specified in the Excel configuration "Devices" tab "**model\_filename**" for IEC 61850 server. The extension of Server Model file using **Wcc Lite 1.7.0** firmware should be **.cfg** but using newer version of Wcc Excel Utility the extension **.server** can be created by default. This can be changed by editing the Server Model file name. Now "convert" button needs to be pressed and the Server Model file will be generated (Fig. 4). After that, this Server Model file needs to be uploaded to Wcc Lite WEB (Fig. 5).

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690295167581.png)

Fig. 4 Generating Server Model file

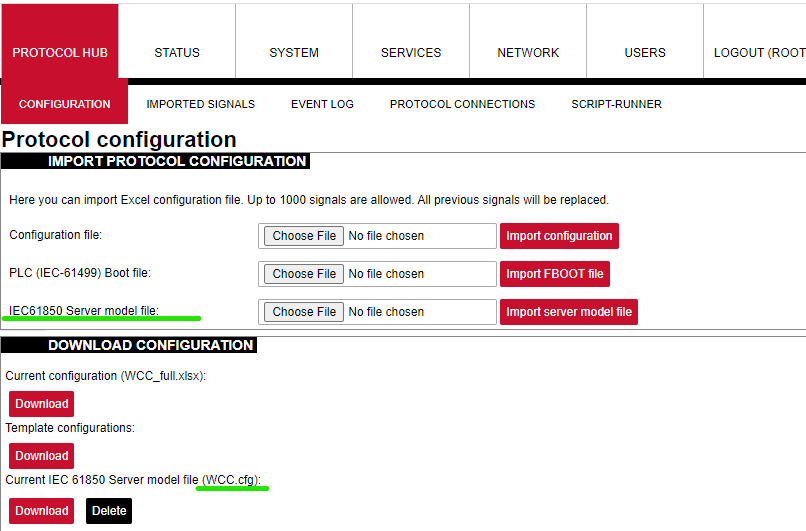

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690295297098.png)

Fig. 5 Uploading IEC 61850 Server Model file to Wcc Lite WEB

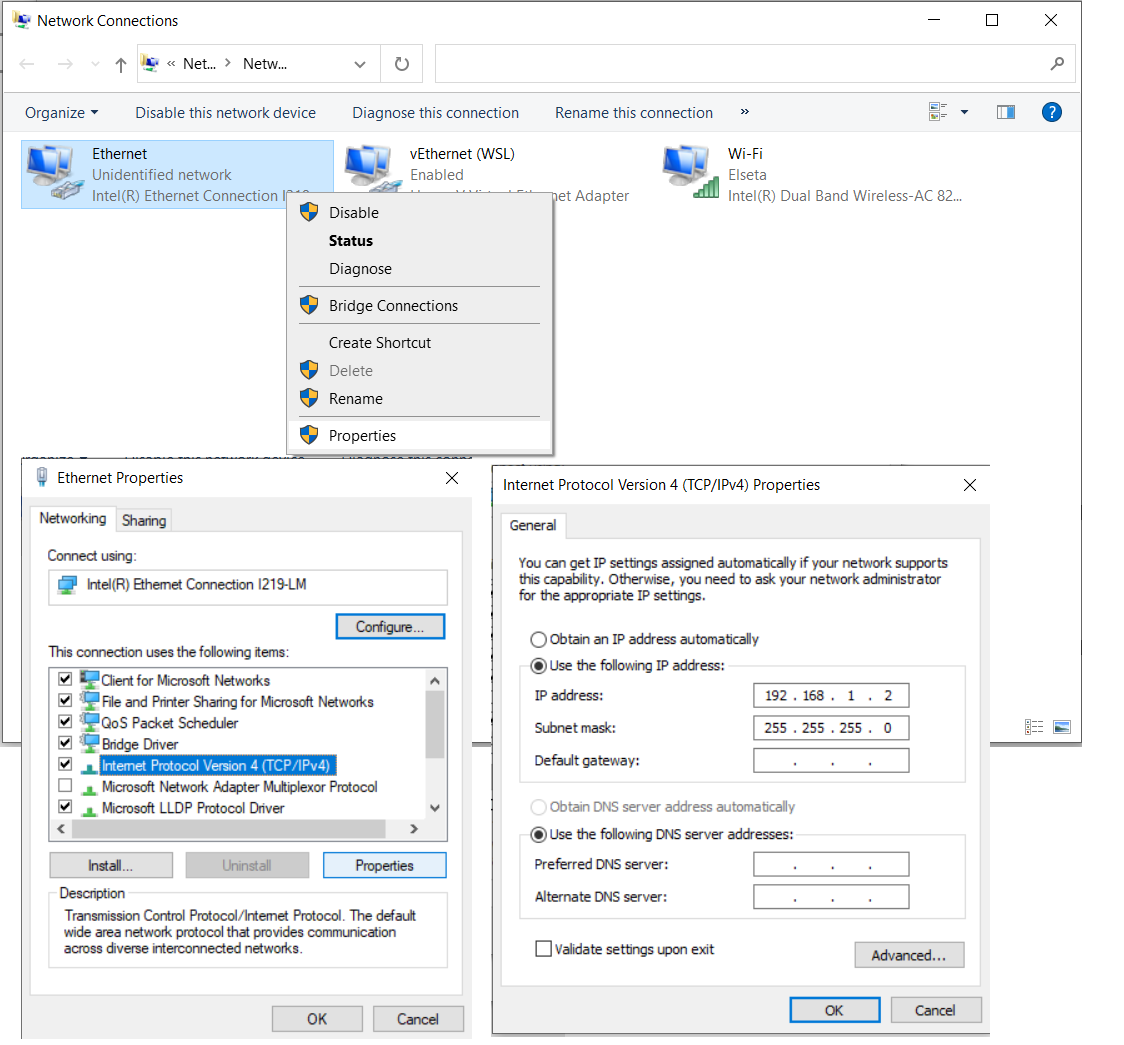

### Uploading Wcc Lite configuration

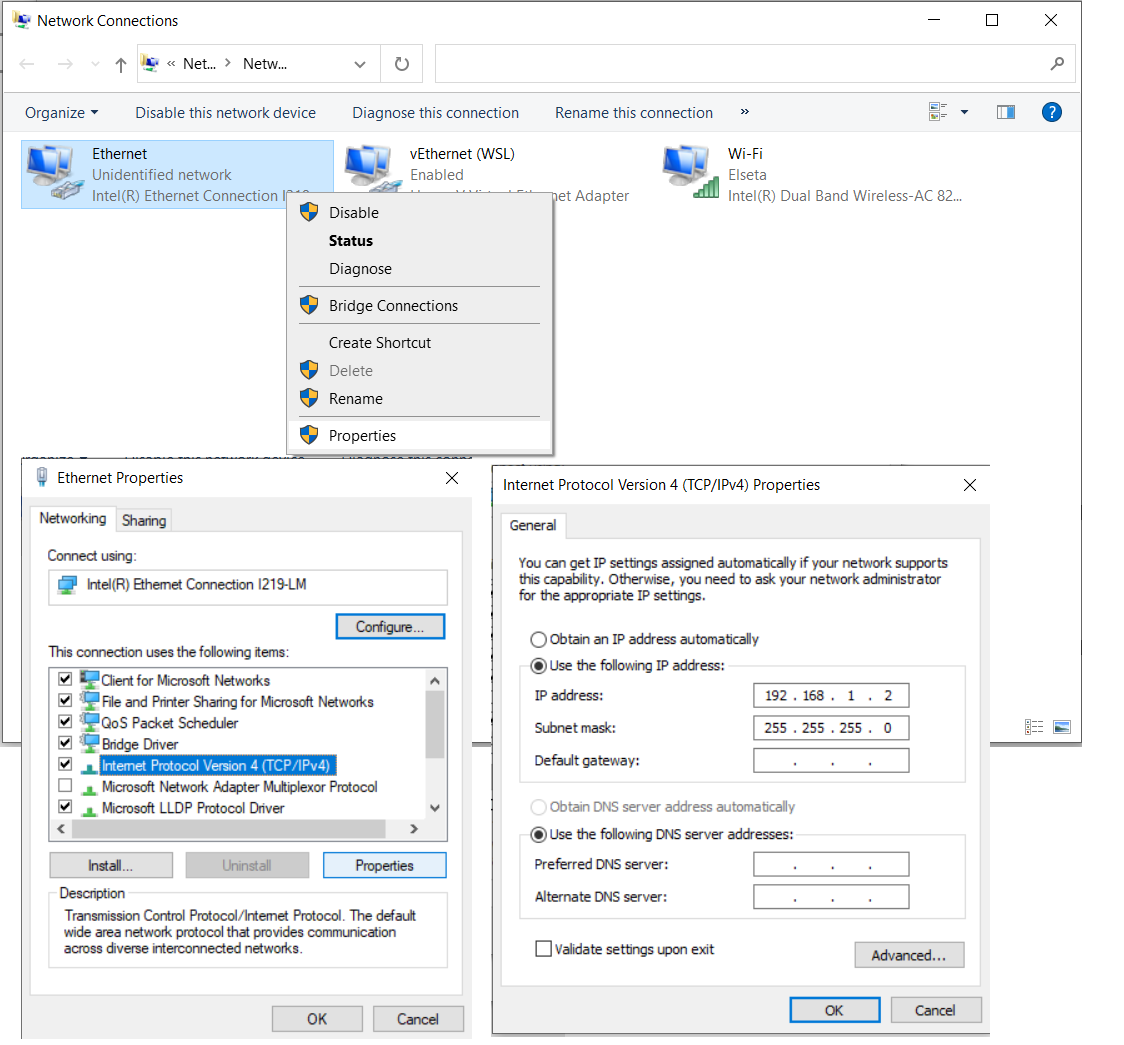

After the Server Model file is uploaded, and made sure that Server Model file name matches the one specified in excel configuration we are now able to upload excel configuration to Wcc Lite. One more thing to notice, in Excel configuration "Devices" sheet "host" parameter for IEC61850 server is 192.168.1.2. This IP should match the PC Ethernet IP, to which Wcc Lite ETH0 port is connected via ETH cable and can be set manually. This is shown in Fig. 6.

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690357201276.png)

Fig. 6 Changing PC IP (TCP/IPv4) to match the Host IP in configuration

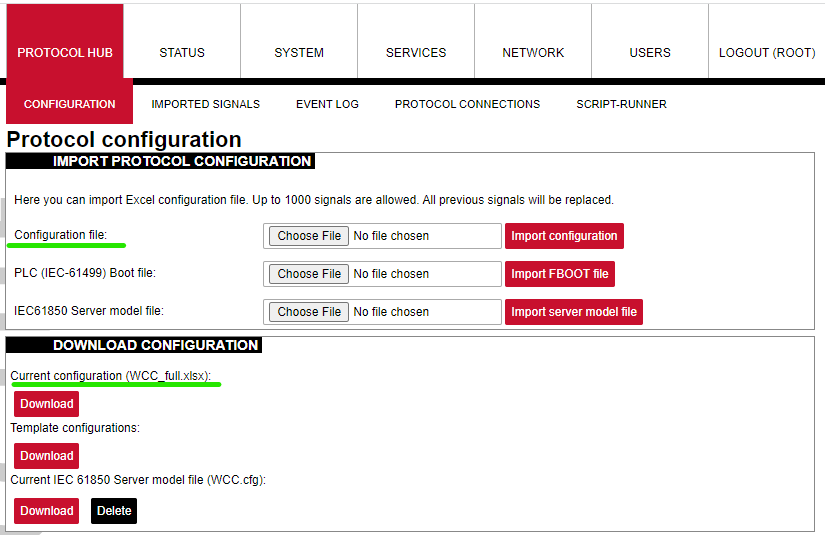

When all parameter described earlier matches the ones specified in configuration, we can upload the configuration to Wcc Lite WEB. It is shown in Fig. 7. Simply choose the Excel configuration and press "import configuration". The upload may take several minutes.

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690357767962.png)

Fig. 7 Uploading Excel configuration to Wcc Lite.

## Starting IEC 61850 server

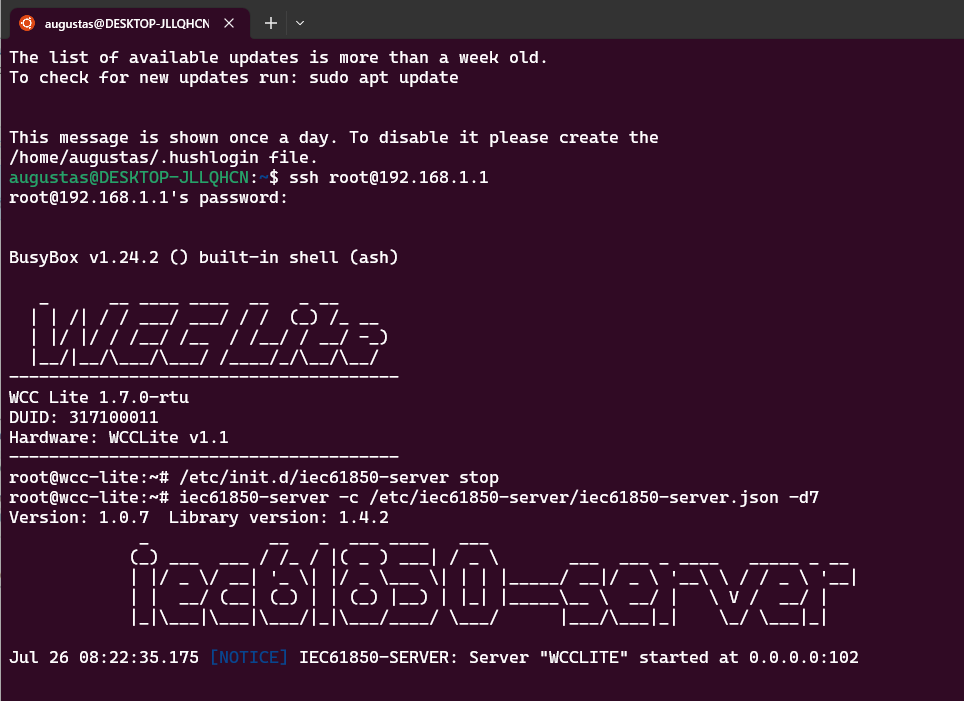

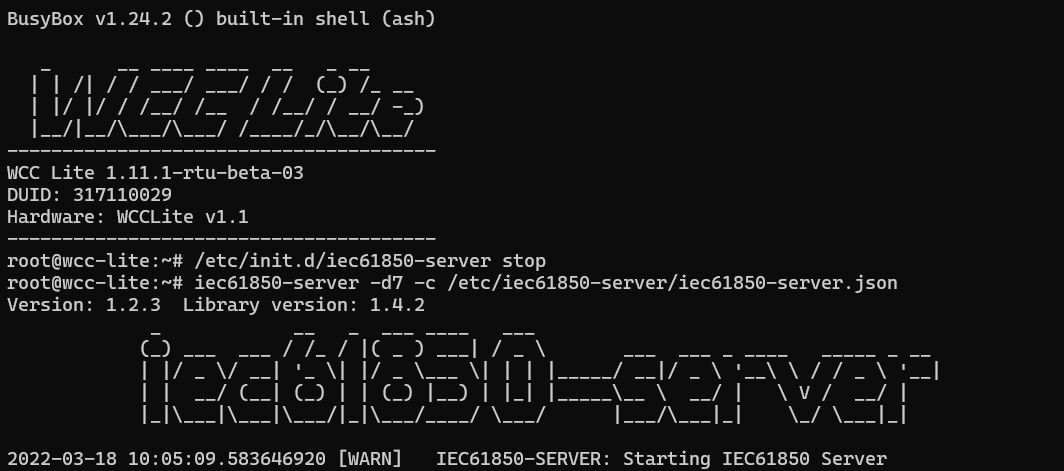

Now, when needed files were uploaded to Wcc Lite, we can start IEC61850 server. For this step the debugger interface will be needed. We prefer using terminal window with installed linux subsystem or other debugger interfaces like PuTTY app. These apps can be found and downloaded on the internet. Firstly we need to connect to Wcc Lite through SSH (using PuTTY, SSH connection type should be chosen and Wcc Lite IP 192.168.1.1 entered). Following commands should be entered in the debugger window:

1\. Connecting to Wcc Lite: **ssh root@192.168.1.1**

2\. Login: **root** Password: **your Wcc Lite pasword**

3\. Stopping the IEC 61850 service: **/etc/init.d/iec61850-server stop**

4\. Starting IEC61850 server in debugger mode: **iec61850-server -c /etc/iec61850-server/iec61850-server.json -d7**

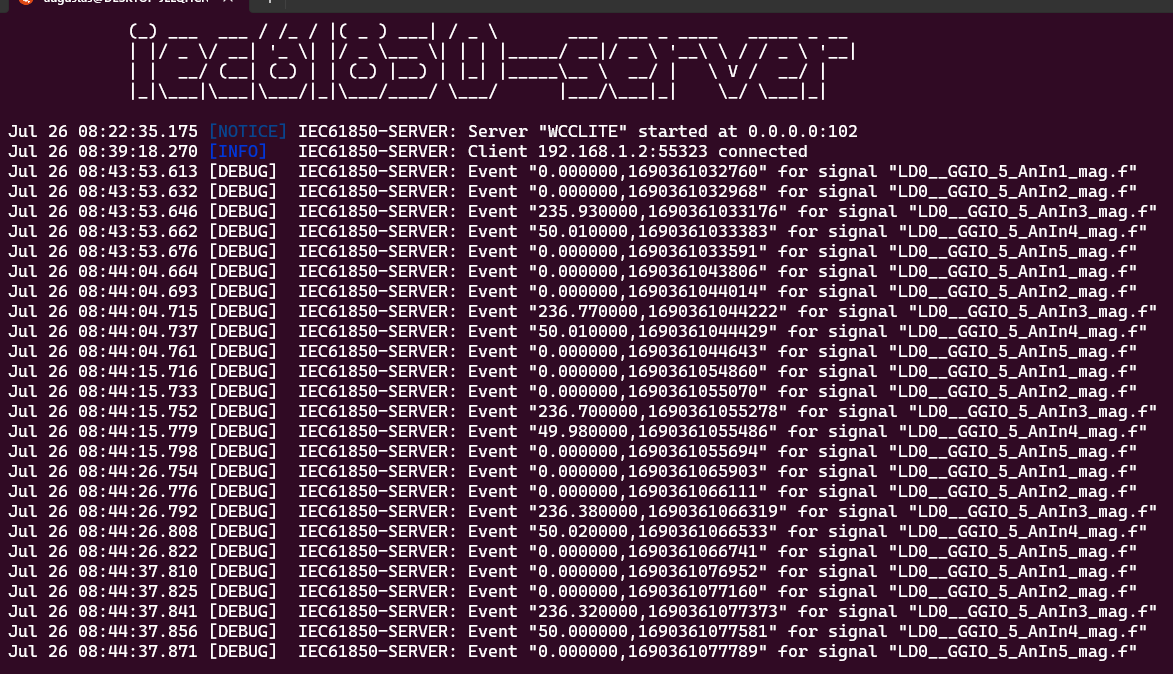

After these commands are executed, the IEC 61850 server is started, it is shown in Fig. 8.

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690359835315.png)

Fig. 8 Connecting to Wcc Lite through SSH and starting IEC61850 server

## Connecting to Wcc Lite (server) on IEDscout (client)

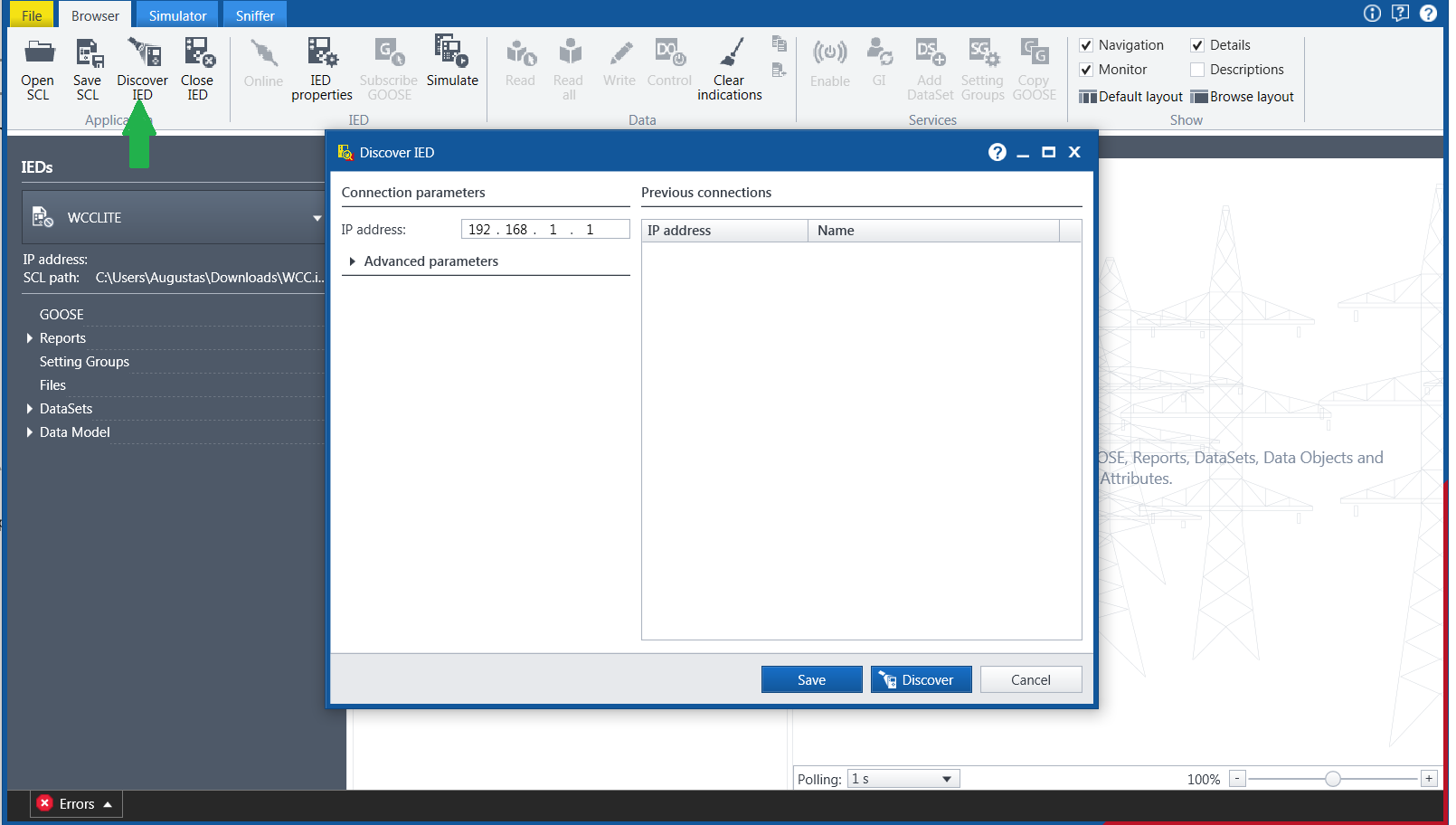

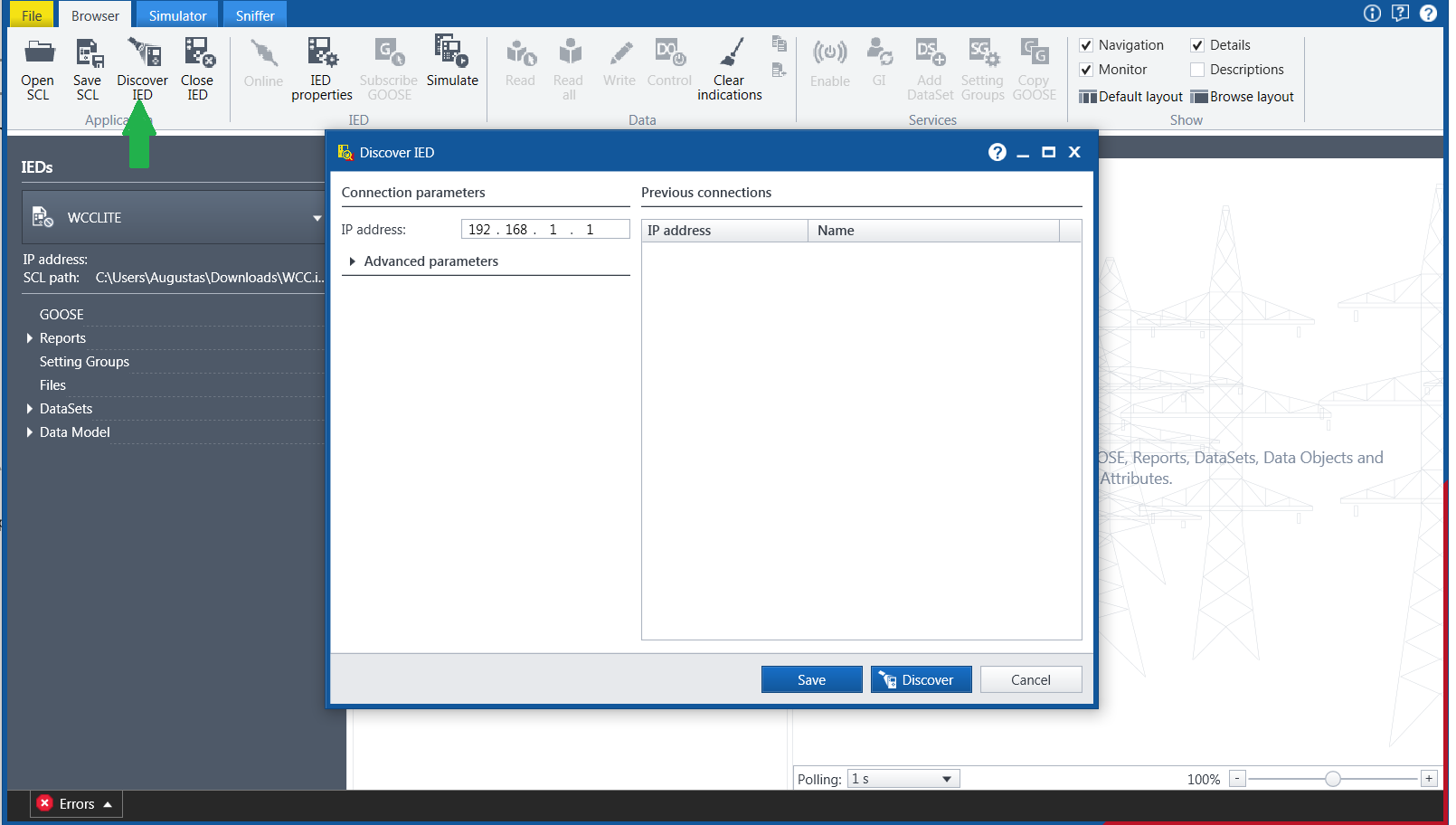

For this step, IEDscout will be needed. IEDScout is an ideal tool for protection and substation automation engineers working with IEC 61850 devices. It provides access to the IEDs (Intelligent Electronic Devices) and performs numerous useful functions when working with them. The software can simulate entire Ed. Also any different but similar functionality software can be used as well. Following steps are done using IEDscout software.

1\. Open IEDscout software, then choose and open ICD file that is needed.

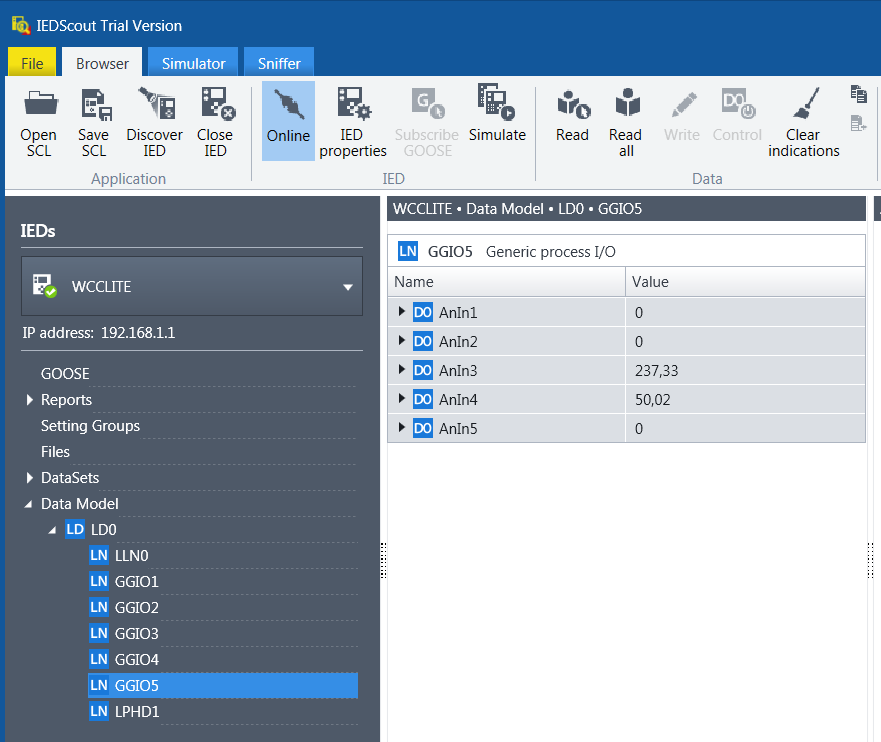

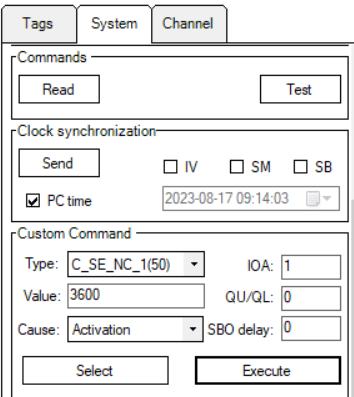

2\. In opened IEDscout Browser window click "Discover IED", then in opened window enter Wcc Lite IP (192.168.1.1) and press "discover" (Fig. 9).

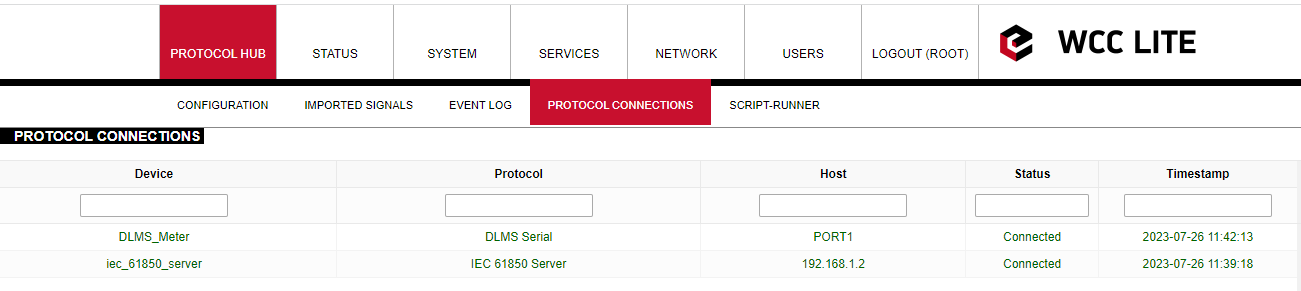

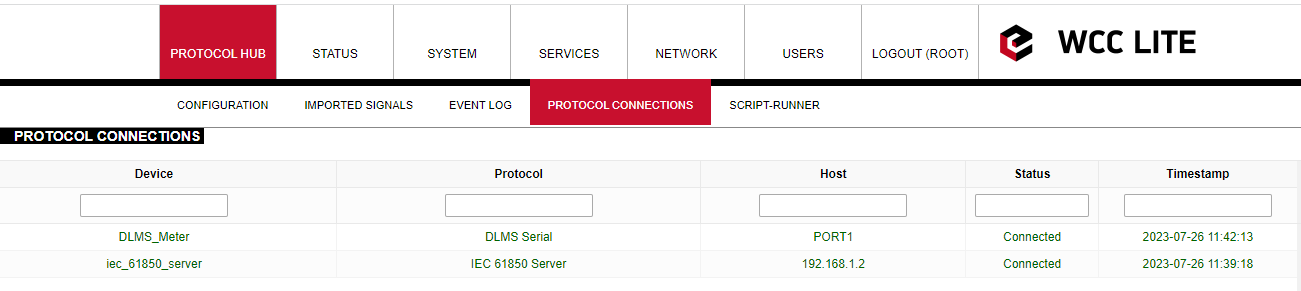

3\. If the Wcc Lite did not connect when "discover" was pressed, then it is needed to press "Online". The indication, that IEC61850 server and Meter with DLMS serial protocol are connected correctly can be seen in Wcc Lite WEB "protocol connections" tab (Fig. 10).

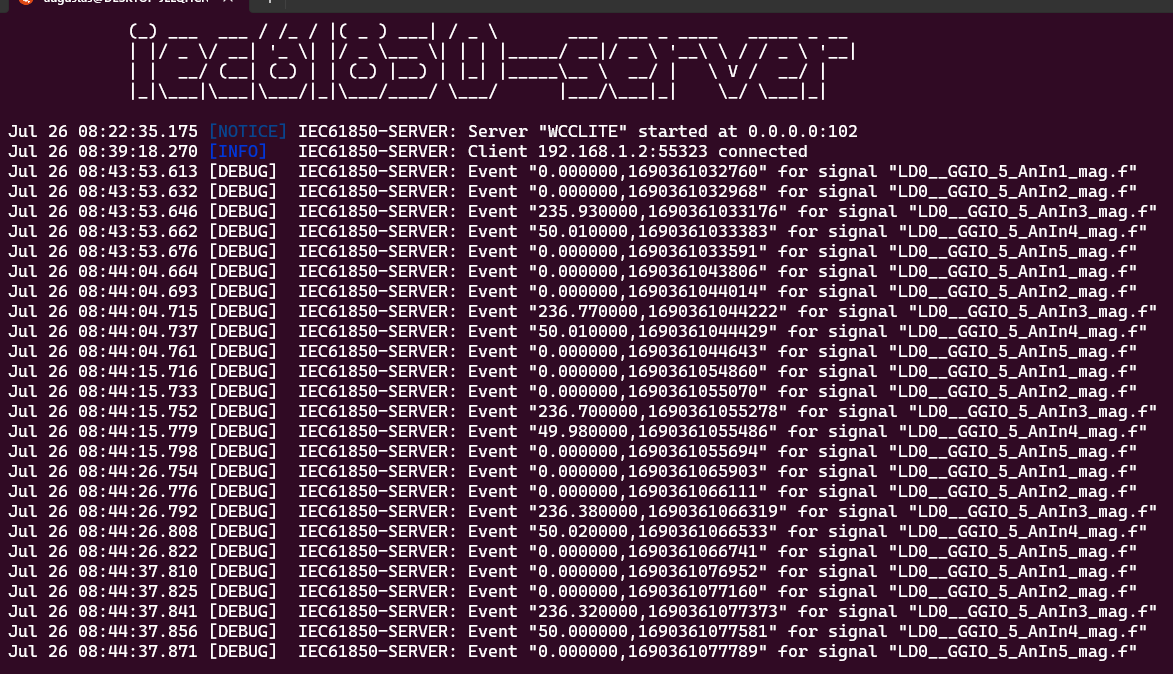

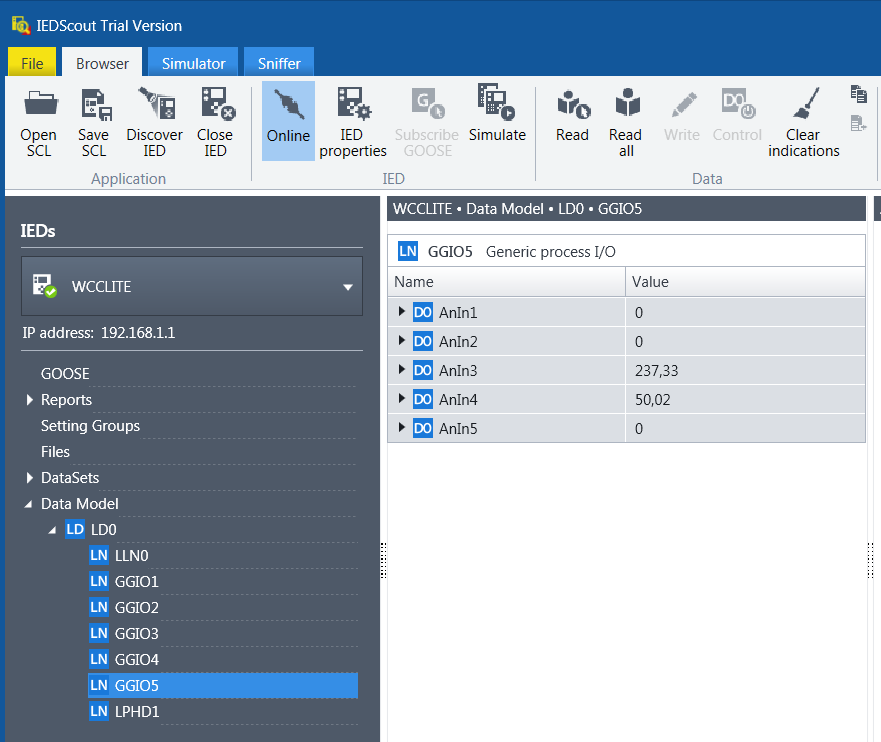

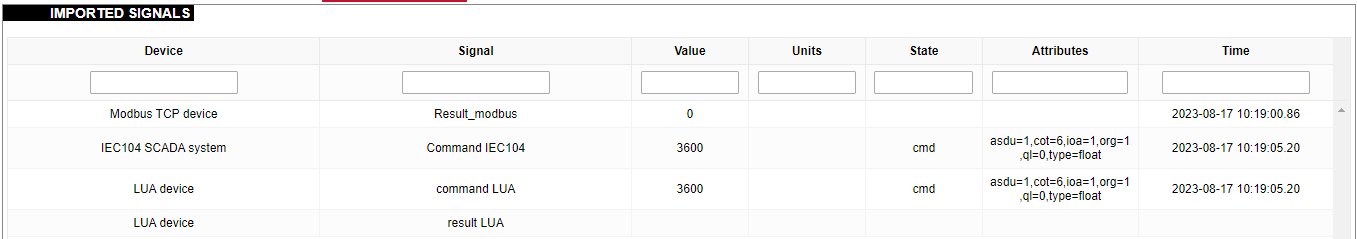

Now Wcc Lite IEC61850 server and IEC61850 client on IEDscout are connected and after few moments we should see measurement from the Meter in the debugger window. When measurements from the Meter appears in debugger window (Fig. 11), press "Read" on IEDscout to update values (Fig. 12).

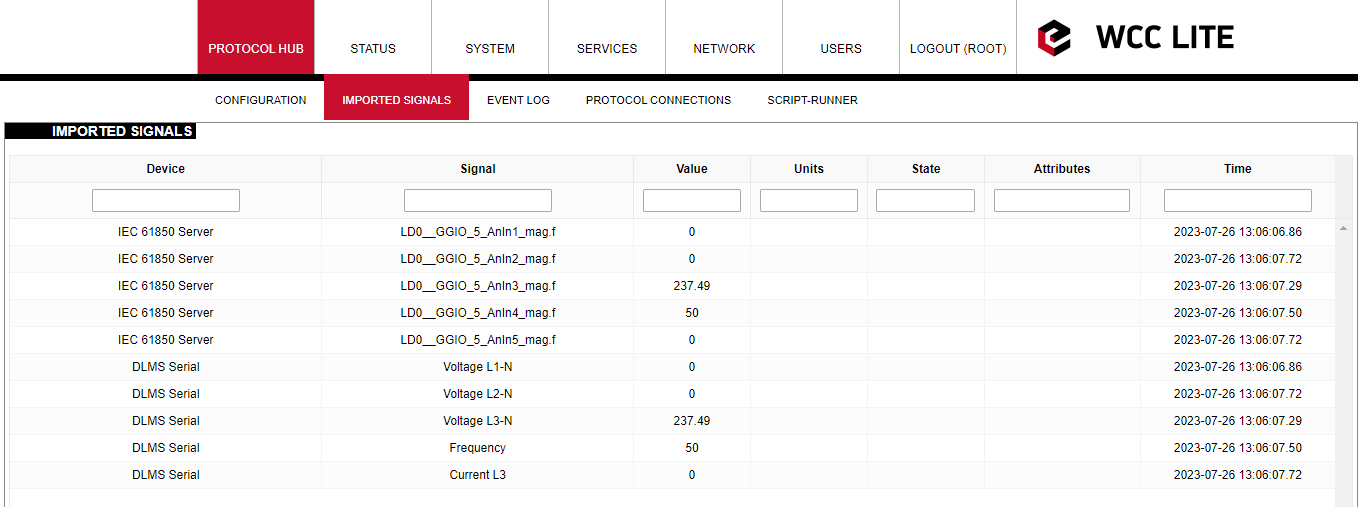

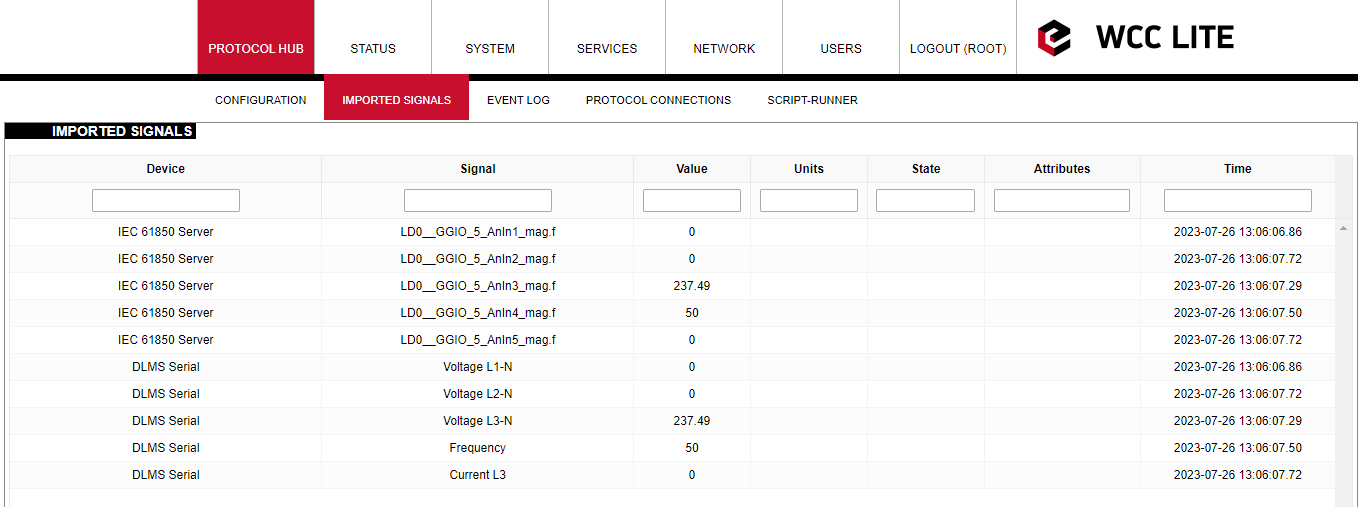

All these measurements are also represented in Wcc Lite WEB. There you can see that it has DLMS serial Meter signals and IEC 61850 server signals all in one place in "Imported signals" tab (Fig. 13).

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690360585596.png)

Fig. 9 Starting IED on IEDscout

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690361170192.png)

Fig. 10 Protocol connections

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690361780503.png)

Fig. 11 Measurements from Meter linked to IEC61850 server signals

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690361918281.png)

Fig. 12 Measurements appeared in IEDscout software

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690365992182.png)

Fig. 13 Measurements represented in Wcc Lite WEB "Imported signals" tab.

#### Files used in this article:

1\. ICD file: [WCC.icd](https://wiki.elseta.com/attachments/602)

2\. Server Model file: [WCC.cfg](https://wiki.elseta.com/attachments/603)

3\. Excel configuration file: [WCC\_full.xlsx](https://wiki.elseta.com/attachments/604)

4\. Excel Utility software: [Excel Utility](https://wiki.elseta.com/attachments/55)

5\. Wcc Lite firmware: [Wcc 1.7.0 RTU](https://wiki.elseta.com/attachments/47)

# DLMS Serial to IEC61850-server protocol conversion (WCC Lite FW: 1.10.0 or newer)

#### Description

This article explains how to configure the WCC Lite to convert data from a DLMS Serial protocol meter to an IEC 61850 server. The process includes device setup, signal mapping, server model creation, configuration upload, and validation through IEDscout.

[](https://wiki.elseta.com/uploads/images/gallery/2023-07/image-1690356504117.png)

Fig 1. Connecting Meter with DLMS serial protocol to WCC Lite and IEC61850 server

#### Preparatiom

To begin, ensure that the WCC Lite is physically installed according to manufacturer's instructions. Connect your computer to the WCC Lite using an Ethernet cable via the ETH0 port. Log in using the default credentials and perform basic setup, including system name, network parameters, and user management. You can find additional assistance in related [How to](https://wiki.elseta.com/books/how-to) articles.

#### Excel configuration

Configuration is done using an Excel file containing two main sheets: Devices and Signals. In the Devices sheet, add a row for the DLMS meter. Specify its communication settings, including serial port parameters, protocol (DLMS), and authentication details. The serial number should also match the connected device.

Add required information for the connected Gama meter with **DLMS Serial** protocol:

**name**

**description**

**device\_alias**

**protocol**

**serial\_number**

**device**

**databits**

**stopbits**

**baudrate**

**parity**

DLMS Serial

DLMS Serial

DLMS\_Meter

DLMS

2250259

PORT1

8

1

4800

none

**flowcontrol**

**enable**

**auth**

**logical\_address**

**address\_size**

**client\_address**

**type**

**mode**

none

1

LOW

1

2

32

SN

DLMS-HDLC

More information about DLMS protocol configuration is provided in [DLMS/COSEM](https://wiki.elseta.com/books/manual-18/page/171-dlmscosem) article.

Next, define a second row for the IEC 61850 server. Assign an alias and bind it to the 0.0.0.0 address. **The model filename you enter here will later be matched to the server model file you generate.** Define the IED name, logical device, access point, and port settings.

Add **IEC 61850 server** protocol required information:

**name**

**description**

**device\_alias**

**protocol**

**bind\_address**

IEC 61850 Server

IEC 61850 Server

iec\_61850\_server

iec 61850 server

0.0.0.0

**ied\_name**

**access\_point**

**port**

**auth**

**host**

**model\_filename**

WCCLITE

LD0

102

NONE

192.168.1.2

WCC\_test

More information about IEC 61850 server protocol configuration is provided in [IEC 61850 server](https://wiki.elseta.com/books/manual-18/page/152-iec-61850-server) article.

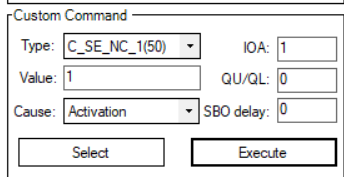

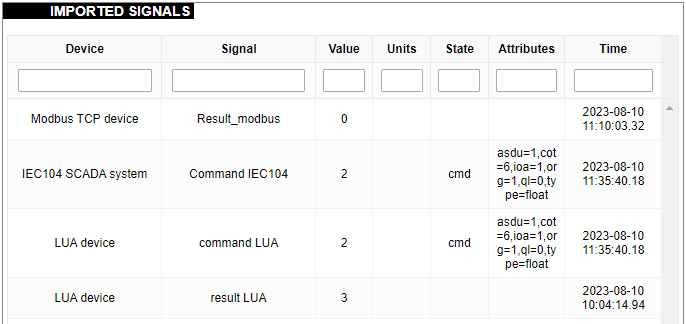

#### Configure signals (Excel "Signals\_DLMS" sheet)